-

Features • Available for all Sensormate sensors (2/4 bridges) • Direct display of the measured values in µe, kN or t • High accuracy and stable reset • Very bright displays and robust aluminum housing (IP52); Ideal for rough environments • USB connection for tie bar adjustment software (optional) • Analog output 0...10VDC (optional)

Features • Available for all Sensormate sensors (2/4 bridges) • Direct display of the measured values in µe, kN or t • High accuracy and stable reset • Very bright displays and robust aluminum housing (IP52); Ideal for rough environments • USB connection for tie bar adjustment software (optional) • Analog output 0...10VDC (optional) -

Features • Available for all Sensormate sensors (2/4 bridges) • Direct display of the measured values in µe, kN or t • High accuracy and stable reset • Automatic reset, external reset and alarm output • Ideal for control cabinet installation (96x96mm, DIN 43700) • Battery operation possible (optional) / not rechargeable

Features • Available for all Sensormate sensors (2/4 bridges) • Direct display of the measured values in µe, kN or t • High accuracy and stable reset • Automatic reset, external reset and alarm output • Ideal for control cabinet installation (96x96mm, DIN 43700) • Battery operation possible (optional) / not rechargeable -

Features • Complete system for the simultaneous strain-measurement on up to four tie bars • Direct display of the measured values in µe, kN or t • Quick and easy non-destructive assembly • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…400mm) • Dynamic applications • 4- channel digital monitor DU4D • USB connection for tie bar adjustment software (optional) • Analog output 0...10VDC (optional) • Very compact and easy to use system

Features • Complete system for the simultaneous strain-measurement on up to four tie bars • Direct display of the measured values in µe, kN or t • Quick and easy non-destructive assembly • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…400mm) • Dynamic applications • 4- channel digital monitor DU4D • USB connection for tie bar adjustment software (optional) • Analog output 0...10VDC (optional) • Very compact and easy to use system -

Features • Complete system for the strain-measurement on one tie bar • Direct display of the measured values in µe, kN or t • Quick and easy non-destructive assembly • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…400mm) • Dynamic applications • 1- channel digital monitor DU1D • Ideal for self-construction load cells • Very compact and easy to use system

Features • Complete system for the strain-measurement on one tie bar • Direct display of the measured values in µe, kN or t • Quick and easy non-destructive assembly • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…400mm) • Dynamic applications • 1- channel digital monitor DU1D • Ideal for self-construction load cells • Very compact and easy to use system -

Features • Complete system for the simultaneous strain-measurement on up to four tie bars • Direct display of strain values in µe, kN or t (via our Inspectmate software) • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 4- channel digital monitor-box DU-4USB • USB connection for tie bar adjustment software and power supply • Very compact and easy to use system

Features • Complete system for the simultaneous strain-measurement on up to four tie bars • Direct display of strain values in µe, kN or t (via our Inspectmate software) • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 4- channel digital monitor-box DU-4USB • USB connection for tie bar adjustment software and power supply • Very compact and easy to use system -

Features • Complete system for the simultaneous strain-measurement on up to four tie bars • Direct display of strain values in µe, kN or t • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 4- channel digital monitor DU4D • USB connection for tie bar adjustment software (optional) • Very compact and easy to use system

Features • Complete system for the simultaneous strain-measurement on up to four tie bars • Direct display of strain values in µe, kN or t • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 4- channel digital monitor DU4D • USB connection for tie bar adjustment software (optional) • Very compact and easy to use system -

Features • Complete system for the strain-measurement on one tie bar • Direct display of strain values in µe, kN or t • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 1- channel digital monitor DU1D • Battery operation possible (optional) / not rechargeable • Very compact and easy to use system

Features • Complete system for the strain-measurement on one tie bar • Direct display of strain values in µe, kN or t • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 1- channel digital monitor DU1D • Battery operation possible (optional) / not rechargeable • Very compact and easy to use system -

Features • Measure strain in any direction in seconds • Smallest press-on sensor with magnet mounting • Direct surface strain reading like bonded strain gages, high linearity on tension and compression • Quick and easy mounting on magnetic structures • Calibrated sensor (K=2.00) for dynamic applications • Ideal for checking FEM calculations and for stress analysis on flat steel structures • Without amplifier (passiv) • External amplifier recommended (e.g. MBA100; VDA, Monitor DU-1D

Features • Measure strain in any direction in seconds • Smallest press-on sensor with magnet mounting • Direct surface strain reading like bonded strain gages, high linearity on tension and compression • Quick and easy mounting on magnetic structures • Calibrated sensor (K=2.00) for dynamic applications • Ideal for checking FEM calculations and for stress analysis on flat steel structures • Without amplifier (passiv) • External amplifier recommended (e.g. MBA100; VDA, Monitor DU-1D -

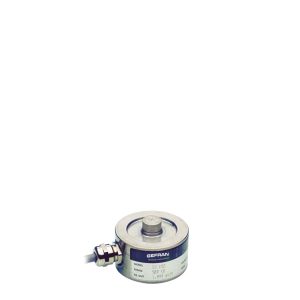

Features • Measurement of nozzle touch force (nozzle pressure force) in injection-molding and die-casting machines • User-friendly, small and compact • Force measurement range: 200kN / 450kN • Very high repeatability • Direct connection to our signal amplifiers and monitors • Various nozzle adapters can be retrofitted (e.g., brass) • Magnetic bases can be retrofitted in different sizes

Features • Measurement of nozzle touch force (nozzle pressure force) in injection-molding and die-casting machines • User-friendly, small and compact • Force measurement range: 200kN / 450kN • Very high repeatability • Direct connection to our signal amplifiers and monitors • Various nozzle adapters can be retrofitted (e.g., brass) • Magnetic bases can be retrofitted in different sizes -

Features • Direct measurement of surface strain • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • Without amplifier (passive)

Features • Direct measurement of surface strain • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • Without amplifier (passive) -

Features • Direct measurement of surface strain • Quick and easy non-destructive assembly • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…400mm) • Dynamic applications • Without amplifier (passive) • Ideal for online monitoring of clamping force • Ideal for self-made load cells

Features • Direct measurement of surface strain • Quick and easy non-destructive assembly • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…400mm) • Dynamic applications • Without amplifier (passive) • Ideal for online monitoring of clamping force • Ideal for self-made load cells -

Features • Direct measurement of surface strain • With integrated digital amplifier • Quick and easy non-destructive assembly • High accuracy and linearity • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…250mm) • Dynamic applications • Ideal for online monitoring of clamping force

Features • Direct measurement of surface strain • With integrated digital amplifier • Quick and easy non-destructive assembly • High accuracy and linearity • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…250mm) • Dynamic applications • Ideal for online monitoring of clamping force -

Features • Measure strain in deep holes • With calibrated digital amplifier • Quick and easy mounting with torque-wrench • High linearity on tension and compression • For dynamic applications • Used in injection moulding and die-casting machines or any cylinder • Very high accuracy (like bonded strain gauges) • Protected against overload

Features • Measure strain in deep holes • With calibrated digital amplifier • Quick and easy mounting with torque-wrench • High linearity on tension and compression • For dynamic applications • Used in injection moulding and die-casting machines or any cylinder • Very high accuracy (like bonded strain gauges) • Protected against overload -

Features • Direct measurement of surface strain • With high grade variable digital amplifier • Amplifies the signal on the spot, avoiding EMC problems • High accuracy and linearity in tension and pressure (like bonded strain gauges) • For dynamic applications • Used on presses, injection moulding and die-casting machines • Quick and easy mounting • Protected against overload

Features • Direct measurement of surface strain • With high grade variable digital amplifier • Amplifies the signal on the spot, avoiding EMC problems • High accuracy and linearity in tension and pressure (like bonded strain gauges) • For dynamic applications • Used on presses, injection moulding and die-casting machines • Quick and easy mounting • Protected against overload -

Features • Small press-on sensor with one-hole mounting • Direct measurement of surface strain • Without amplifier (passiv) • High accuracy and linearity in tension and pressure (like bonded strain gauges) • For dynamic applications • Used on presses, injection moulding and die-casting machines • Quick and easy mounting • Protected against overload • Optional accessories: - Signal amplifier VDA - Monitor DU-1D

Features • Small press-on sensor with one-hole mounting • Direct measurement of surface strain • Without amplifier (passiv) • High accuracy and linearity in tension and pressure (like bonded strain gauges) • For dynamic applications • Used on presses, injection moulding and die-casting machines • Quick and easy mounting • Protected against overload • Optional accessories: - Signal amplifier VDA - Monitor DU-1D -

Features The W92 is a melt pressure and temperature monitoring system which comes complete with the following items: • W32-6-M-xxxx-1-4-D-000 (oil-filled melt pressure transducer with type “J” thermocouple) • 40TB-10-RRR-2-0-1 (1/4 DIN pressure and temperature indicator) • C08WLS (25 foot 6-pin cable) • SF18 (mounting bracket)

Features The W92 is a melt pressure and temperature monitoring system which comes complete with the following items: • W32-6-M-xxxx-1-4-D-000 (oil-filled melt pressure transducer with type “J” thermocouple) • 40TB-10-RRR-2-0-1 (1/4 DIN pressure and temperature indicator) • C08WLS (25 foot 6-pin cable) • SF18 (mounting bracket) -

Features The M92 is a melt pressure and temperature monitoring system which comes complete with the following items: • M32-6-M-xxxx-1-4-D-000 (melt pressure transducer with type “J” thermocouple) • 40TB-10-RRR-2-0-1 (1/4 DIN pressure and temperature indicator) • C08WLS (25 foot 6-pin cable) • SF18 (mounting bracket)

Features The M92 is a melt pressure and temperature monitoring system which comes complete with the following items: • M32-6-M-xxxx-1-4-D-000 (melt pressure transducer with type “J” thermocouple) • 40TB-10-RRR-2-0-1 (1/4 DIN pressure and temperature indicator) • C08WLS (25 foot 6-pin cable) • SF18 (mounting bracket) -

Features • Ranges: from 0...3 to 0...1000 bar and ranges from -1...+1 to -1...+10 bar • Output signal 4...20mA 2-wires / 0.1...5.1Vdc /0.1...10.1Vdc / 0...5Vdc / 0...10Vdc / 1...5Vdc / 1...10Vdc • Protection rating: IP65/IP67 • Wetted parts AISI 430F and 17-4PH • Available with a variety of process connections, both standard and custom

Features • Ranges: from 0...3 to 0...1000 bar and ranges from -1...+1 to -1...+10 bar • Output signal 4...20mA 2-wires / 0.1...5.1Vdc /0.1...10.1Vdc / 0...5Vdc / 0...10Vdc / 1...5Vdc / 1...10Vdc • Protection rating: IP65/IP67 • Wetted parts AISI 430F and 17-4PH • Available with a variety of process connections, both standard and custom