-

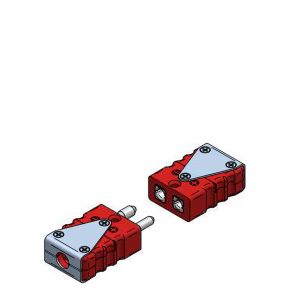

Features • Body of ultra-high temp thermoset compound with original thermocouple material pins and springloaded inserts. • Polarized pins ensure proper connection. • Easy wire connection through sandwich construction. • Molded barriers prevent short circuit. • Rugged one body design. • Stainless steel bracket and screws for usage in robust environment

Features • Body of ultra-high temp thermoset compound with original thermocouple material pins and springloaded inserts. • Polarized pins ensure proper connection. • Easy wire connection through sandwich construction. • Molded barriers prevent short circuit. • Rugged one body design. • Stainless steel bracket and screws for usage in robust environment -

D120 Series Family

D120 Series Family- D123-PP 900 - 2200 l/h

- D123-PVDF 900 - 2200 l/h

- D124-PP 900 - 4000 l/h

- D124-PVDF 900 - 4000 l/h

- D125-PP 900 - 7500 l/h

- D125-PVDF 900 - 7500 l/h

- D126-PP 900 - 9000 l/h

- D126-PVDF 900 - 9000 l/h

-

D13 Series Family

D13 Series Family- D13-08-300-PP 2000 - 8000 l/h

- D13-10-300-PP 2000 - 10000 l/h

- D13-12-300-PP 2000 - 12000 l/h

-

D16 Series Family

D16 Series Family- D16-05-260-SS 1700 - 5000 l/h

- D16-07-260-SS 1700 - 7000 l/h

- D16-14-400-SS 1700 - 13500 l/h

- D16-17-400-SS 1700 - 17000 l/h

- D16-21-400-SS 1700 - 21000 l/h

- D16-32-400-SS 1700 - 32000 l/h

-

D18 Series Family

D18 Series Family- D18-14-400-PP 12000 - 14000 l/h

- D18-14-400-PVDF 12000 - 23000 l/h

- D18-18-400-PP 12000 - 18000 l/h

- D18-18-400-PVDF 12000 - 18000 l/h

- D18-23-400-PP 12000 - 23000 l/h

- D18-23-400-PVDF 12000 - 23000 l/h

- D18-30-400-PP 12000 - 30000 l/h

- D18-30-400-PVDF 12000 - 30000 l/h

- D18-36-400-PP 12000 - 36000 l/h

- D18-36-400-PVDF 12000 - 36000 l/h

- D18-43-400-PP 12000 - 43000 l/h

- D18-43-400-PVDF 12000 - 43000 l/h

- D18-05-HD-400-PP Qmax 5000 l/h

- D18-05-HD-400-PVDF Qmax 5000 l/h

- D18-10-HD-400-PP Qmax 10000 l/h

-

D20 Series Family

D20 Series Family- D20-40/20-PP 20 - 40 m3/h

- D20-45/25-PP 20 - 45 m3/h

- D20-50/28-PP 20 - 50 m3/h

- D20-50/31-PP 20 - 54 m3/h

-

D24 Series Family

D24 Series Family- D24-50/27-PP 20 - 65 m3/h

- D24-55/35-PP 20 - 54 m3/h

- D24-60/29-PP 20 - 73 m3/h

- D24-60/42-PP 20 - 54 m3/h

- D24-65/37-PP 20 - 54 m3/h

- D24-70/42-PP 20 - 82 m3/h

-

D30 Series Family

D30 Series Family- D33-90/14-PP 40 - 70 m3/h

- D33-100/14-PP 40 - 90 m3/h

- D33-110/16-PP 40 - 98 m3/h

- D35-130/14-PP 40 - 132 m3/h

- D35-150/15-PP 40 - 143 m3/h

- D39-180/17-PP 40 - 180 m3/h

-

D43 Series Family

D43 Series Family- 43-400-PP 40 - 180 m3/h

- D43-600-PP 40 - 180 m3/h

-

D90 Series Family

D90 Series Family- D91-PP 600 - 1600 l/h

- D91-PVDF 600 - 1600 l/h

- D92-PP 600 - 2200 l/h

- D92-PVDF 600 - 2200 l/h

- D93-PP 600 - 3300 l/h

- D93-PVDF 600 - 3300 l/h

- D94-PP 600 - 4400 l/h

- D94-PVDF 600 - 4400 l/h

- D95-PP 600 - 6000 l/h

- D95-PVDF 600 - 6000 l/h

-

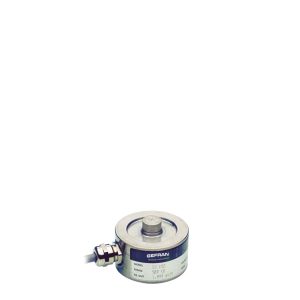

Features • Measurement of nozzle touch force (nozzle pressure force) in injection-molding and die-casting machines • User-friendly, small and compact • Force measurement range: 200kN / 450kN • Very high repeatability • Direct connection to our signal amplifiers and monitors • Various nozzle adapters can be retrofitted (e.g., brass) • Magnetic bases can be retrofitted in different sizes

Features • Measurement of nozzle touch force (nozzle pressure force) in injection-molding and die-casting machines • User-friendly, small and compact • Force measurement range: 200kN / 450kN • Very high repeatability • Direct connection to our signal amplifiers and monitors • Various nozzle adapters can be retrofitted (e.g., brass) • Magnetic bases can be retrofitted in different sizes -

Features

Features- Very easy, leak free, in-tank installation

- Filter chamber with welded bottom (no seal)

- Discs (thin/thick paper, cloth), cartridges or bags

- Including complete +GF+ union

- EPDM elastomers for PP and FPM for PVDF

- Including suction strainer

- Max. temperature PP 80°C, PVDF 100°C

- Stainless steel fittings, fasteners and type shields

- Pressure gauge and air release

- High quality European, purpose designed electric motor: - 3 phase, 50/60 Hz, 2900/3500 rpm, IP55, multi voltage - with double layer 2C chemical resistant coating - full length SS shaft with PP/PVDF protection pipe - including PP drip cover, fan cover and wiring box - suitable for frequency drive control

-

Features

Features- Very easy, leak free, in-tank installation

- Filter chamber with welded bottom (no seal)

- Discs (thin/thick paper, cloth), cartridges or bags

- Including complete +GF+ union

- EPDM elastomers for PP and FPM for PVDF

- Including suction strainer

- Max. temperature PP 80°C, PVDF 100°C

- Stainless steel fittings, fasteners and type shields

- Pressure gauge and air release

- High quality European, purpose designed electric motor: - 3 phase, 50/60 Hz, 2900/3500 rpm, IP55, multi voltage - with double layer 2C chemical resistant coating - full length SS shaft with PP/PVDF protection pipe - including PP drip cover, fan cover and wiring box - suitable for frequency drive control

-

Features

Features- Very easy, leak free, in-tank installation

- Filter chamber with welded bottom (no seal)

- Filter media discs, cartridge or bag

- EPDM elastomers for PP and FPM for PVDF

- Including suction strainer

- Max. temperature PP 80°C, PVDF 100°C

- Stainless steel fittings, fasteners and type shields

- Air release

- High quality European, purpose designed electric motor: - 3 phase, 50/60 Hz, 2900/3500 rpm, IP55, multi voltage - with double layer 2C chemical resistant coating - full length SS shaft with PP/PVDF protection pipe - including PP drip cover, fan cover and wiring box - suitable for frequency drive control

-

Features

Features- Magnetic drive pump,

- 100% air tight

-

Features • ATEX and IECEx approval -Ex ia IIC T4 Ga -Ex ia IIIC T135°C Da • 3 wire RTD or thermocouple input • Universal temperature RTD and thermocouple input • 6 digit alpha-numeric LCD display • Approx 8mm display, non-backlit -6 digits,14 segment input value plus “Warning” icon. -Resolution to one decimal place with unit character. -Up to two decimal places (no units displayed with 2 dec place configuration). • 2 x AAA 1.5 V Lithium, Energizer L92 Battery Power (approx. 2-3 years life at 10 sec log interval) • Push-button and NFC configuration • Data logger (NFC interface) up to 1500 temperature measurements stored

Features • ATEX and IECEx approval -Ex ia IIC T4 Ga -Ex ia IIIC T135°C Da • 3 wire RTD or thermocouple input • Universal temperature RTD and thermocouple input • 6 digit alpha-numeric LCD display • Approx 8mm display, non-backlit -6 digits,14 segment input value plus “Warning” icon. -Resolution to one decimal place with unit character. -Up to two decimal places (no units displayed with 2 dec place configuration). • 2 x AAA 1.5 V Lithium, Energizer L92 Battery Power (approx. 2-3 years life at 10 sec log interval) • Push-button and NFC configuration • Data logger (NFC interface) up to 1500 temperature measurements stored -

Features • Available for all Sensormate sensors (2/4 bridges) • Direct display of the measured values in µe, kN or t • High accuracy and stable reset • Automatic reset, external reset and alarm output • Ideal for control cabinet installation (96x96mm, DIN 43700) • Battery operation possible (optional) / not rechargeable

Features • Available for all Sensormate sensors (2/4 bridges) • Direct display of the measured values in µe, kN or t • High accuracy and stable reset • Automatic reset, external reset and alarm output • Ideal for control cabinet installation (96x96mm, DIN 43700) • Battery operation possible (optional) / not rechargeable -

Features • Available for all Sensormate sensors (2/4 bridges) • Direct display of the measured values in µe, kN or t • High accuracy and stable reset • Very bright displays and robust aluminum housing (IP52); Ideal for rough environments • USB connection for tie bar adjustment software (optional) • Analog output 0...10VDC (optional)

Features • Available for all Sensormate sensors (2/4 bridges) • Direct display of the measured values in µe, kN or t • High accuracy and stable reset • Very bright displays and robust aluminum housing (IP52); Ideal for rough environments • USB connection for tie bar adjustment software (optional) • Analog output 0...10VDC (optional)