-

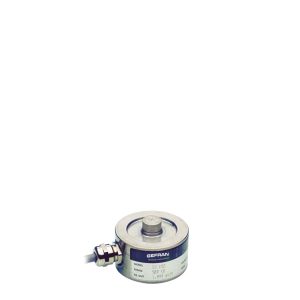

Features • Measurement of nozzle touch force (nozzle pressure force) in injection-molding and die-casting machines • User-friendly, small and compact • Force measurement range: 200kN / 450kN • Very high repeatability • Direct connection to our signal amplifiers and monitors • Various nozzle adapters can be retrofitted (e.g., brass) • Magnetic bases can be retrofitted in different sizes

Features • Measurement of nozzle touch force (nozzle pressure force) in injection-molding and die-casting machines • User-friendly, small and compact • Force measurement range: 200kN / 450kN • Very high repeatability • Direct connection to our signal amplifiers and monitors • Various nozzle adapters can be retrofitted (e.g., brass) • Magnetic bases can be retrofitted in different sizes -

Features • Available for all Sensormate sensors (2/4 bridges) • Direct display of the measured values in µe, kN or t • High accuracy and stable reset • Automatic reset, external reset and alarm output • Ideal for control cabinet installation (96x96mm, DIN 43700) • Battery operation possible (optional) / not rechargeable

Features • Available for all Sensormate sensors (2/4 bridges) • Direct display of the measured values in µe, kN or t • High accuracy and stable reset • Automatic reset, external reset and alarm output • Ideal for control cabinet installation (96x96mm, DIN 43700) • Battery operation possible (optional) / not rechargeable -

Features • Available for all Sensormate sensors (2/4 bridges) • Direct display of the measured values in µe, kN or t • High accuracy and stable reset • Very bright displays and robust aluminum housing (IP52); Ideal for rough environments • USB connection for tie bar adjustment software (optional) • Analog output 0...10VDC (optional)

Features • Available for all Sensormate sensors (2/4 bridges) • Direct display of the measured values in µe, kN or t • High accuracy and stable reset • Very bright displays and robust aluminum housing (IP52); Ideal for rough environments • USB connection for tie bar adjustment software (optional) • Analog output 0...10VDC (optional) -

Features • Direct measurement of surface strain • Quick and easy non-destructive assembly • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…400mm) • Dynamic applications • Without amplifier (passive) • Ideal for online monitoring of clamping force • Ideal for self-made load cells

Features • Direct measurement of surface strain • Quick and easy non-destructive assembly • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…400mm) • Dynamic applications • Without amplifier (passive) • Ideal for online monitoring of clamping force • Ideal for self-made load cells -

Features • Direct measurement of surface strain • With integrated digital amplifier • Quick and easy non-destructive assembly • High accuracy and linearity • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…250mm) • Dynamic applications • Ideal for online monitoring of clamping force

Features • Direct measurement of surface strain • With integrated digital amplifier • Quick and easy non-destructive assembly • High accuracy and linearity • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…250mm) • Dynamic applications • Ideal for online monitoring of clamping force -

Features • Complete system for the strain-measurement on one tie bar • Direct display of the measured values in µe, kN or t • Quick and easy non-destructive assembly • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…400mm) • Dynamic applications • 1- channel digital monitor DU1D • Ideal for self-construction load cells • Very compact and easy to use system

Features • Complete system for the strain-measurement on one tie bar • Direct display of the measured values in µe, kN or t • Quick and easy non-destructive assembly • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…400mm) • Dynamic applications • 1- channel digital monitor DU1D • Ideal for self-construction load cells • Very compact and easy to use system -

Features • Complete system for the simultaneous strain-measurement on up to four tie bars • Direct display of the measured values in µe, kN or t • Quick and easy non-destructive assembly • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…400mm) • Dynamic applications • 4- channel digital monitor DU4D • USB connection for tie bar adjustment software (optional) • Analog output 0...10VDC (optional) • Very compact and easy to use system

Features • Complete system for the simultaneous strain-measurement on up to four tie bars • Direct display of the measured values in µe, kN or t • Quick and easy non-destructive assembly • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…400mm) • Dynamic applications • 4- channel digital monitor DU4D • USB connection for tie bar adjustment software (optional) • Analog output 0...10VDC (optional) • Very compact and easy to use system -

Features

Features- Measurement range : ±10° ±15° ±20° ±30° ±45° ±60° ±85° (dual axis XY); 360° (±180°) (single axis Z)

- Supply voltage: +5Vdc (only for 0.5..4.5Vdc output); +10…+36Vdc (see output signal for right supply voltage)

- Output signal: 0.5...4.5V RATIOMETRIC (supply +5Vdc); 0.5...4.5V; 0...10V; 4...20mA; CANopen

- Electrical connections: AMP Superseal 6P 282108-1; 6 wires output 18 AWG 1.65mm OD (cable+connector on request)

- Resolution: 0.05° (±10° to ±20°); 0.05°(±30°); 0.1°(±45°); 0.1°(±60°); 0.1°(±85°); 0.1° (±180°) analog output; 0.05° CANopen output

-

Features • Measurement range: ±180° different values on request programmable in steps of ±15° (ONLY for analogue versions) • Supply voltage: +5Vdc (only for 0.5..4.5Vdc output); +9…+36Vdc (see output signal for right supply voltage) • Output signal : 0.5...4.5V Ratiometric (supply +5Vdc); 0.5...4.5V; 0...10V; 4...20mA; CANopen, SAE J1939 • Electrical connections: AMP Superseal 6P 282108-1; DEUTSCH 6P DT04-6P • Resolution and speed of rotation: 12 bit (analog output); 14 bit (CANopen/SAE J1939 output); 120 rpm max. • Linearity: < ± 0.5% FS • Working and coefficient temperature: -40°C ... +85°C (higher values on request); thermal drift < 50 ppm/°C

Features • Measurement range: ±180° different values on request programmable in steps of ±15° (ONLY for analogue versions) • Supply voltage: +5Vdc (only for 0.5..4.5Vdc output); +9…+36Vdc (see output signal for right supply voltage) • Output signal : 0.5...4.5V Ratiometric (supply +5Vdc); 0.5...4.5V; 0...10V; 4...20mA; CANopen, SAE J1939 • Electrical connections: AMP Superseal 6P 282108-1; DEUTSCH 6P DT04-6P • Resolution and speed of rotation: 12 bit (analog output); 14 bit (CANopen/SAE J1939 output); 120 rpm max. • Linearity: < ± 0.5% FS • Working and coefficient temperature: -40°C ... +85°C (higher values on request); thermal drift < 50 ppm/°C -

Features • Measurement range: ±180° - different values on request programmable in steps of ±15° (ONLY for analogue versions) • Supply voltage: +5Vdc (only for 0.5..4.5Vdc output); +9…+36Vdc (see output signal for right supply voltage) • Output signal: 0.5...4.5V RATIOMETRIC (supply +5Vdc); 0.5...4.5V; 0...10V; 4...20mA; CANopen, SAE J1939 • Electrical connections: AMP Superseal 6P 282108-1; cable output 18 AWG 1.65mm OD • Resolution and speed of rotation: 12 bit (analog output); 14 bit (CANopen/SAE J1939 output); 120 rpm max. • Linearity: < ±0.5%FS • Working and coefficient temperature: -40°C ... +85°C (higher values on request); thermal drift < 50 ppm/°C

Features • Measurement range: ±180° - different values on request programmable in steps of ±15° (ONLY for analogue versions) • Supply voltage: +5Vdc (only for 0.5..4.5Vdc output); +9…+36Vdc (see output signal for right supply voltage) • Output signal: 0.5...4.5V RATIOMETRIC (supply +5Vdc); 0.5...4.5V; 0...10V; 4...20mA; CANopen, SAE J1939 • Electrical connections: AMP Superseal 6P 282108-1; cable output 18 AWG 1.65mm OD • Resolution and speed of rotation: 12 bit (analog output); 14 bit (CANopen/SAE J1939 output); 120 rpm max. • Linearity: < ±0.5%FS • Working and coefficient temperature: -40°C ... +85°C (higher values on request); thermal drift < 50 ppm/°C -

Features • Pressure ranges from: 0-17 to 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FS (H); < ±0.5% FS (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). • SIL2 and PL d approvals for Functional Safety • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi (up to 400°C/750°F) • Stem material: 17-4 PH

Features • Pressure ranges from: 0-17 to 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FS (H); < ±0.5% FS (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). • SIL2 and PL d approvals for Functional Safety • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi (up to 400°C/750°F) • Stem material: 17-4 PH -

Principal Characteristics • Transducer with exposed tracks, allowing rod diameter is reduced to be reduced to a minimum to permit installation in small cylinders. • Thanks to a special constructive technique, the IC transducer provides high resistance to the working pressures of oil-pressure cylinders (max 340 bar) • Available with internal flanges or external threads to guarantee mechanical compatibility with all principal cylinder types.

Principal Characteristics • Transducer with exposed tracks, allowing rod diameter is reduced to be reduced to a minimum to permit installation in small cylinders. • Thanks to a special constructive technique, the IC transducer provides high resistance to the working pressures of oil-pressure cylinders (max 340 bar) • Available with internal flanges or external threads to guarantee mechanical compatibility with all principal cylinder types. -

Features • Pressure ranges from: 0-17 to 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FS (H); < ±0.5% FS (M) • “Mercury free” hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi up to 400°C (750°F) • Stem material: 17-4 PH • IO-Link output, ready for “Industry 4.0” • Rangeabilty: 3:1 • PLd and SIL2 approvals for Functional safety • Autozero function • Auxiliary information over IO-Link protocol

Features • Pressure ranges from: 0-17 to 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FS (H); < ±0.5% FS (M) • “Mercury free” hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi up to 400°C (750°F) • Stem material: 17-4 PH • IO-Link output, ready for “Industry 4.0” • Rangeabilty: 3:1 • PLd and SIL2 approvals for Functional safety • Autozero function • Auxiliary information over IO-Link protocol -

Features • Pressure ranges from: 0-35 to 0-1000 bar / 0-500 to 0-15000 psi • Accuracy <±0.25% FSO (H); <±0.5% FSO (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. NaK is defined as a safe substance (GRAS • Quantity of NaK contained per model: K30 series (30mm³) [0.00183 in³], K31-K32-K33 series (40mm³) [0.00244 in³] • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi up to 400°C (750°F) • Stem material: 17-4 PH

Features • Pressure ranges from: 0-35 to 0-1000 bar / 0-500 to 0-15000 psi • Accuracy <±0.25% FSO (H); <±0.5% FSO (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. NaK is defined as a safe substance (GRAS • Quantity of NaK contained per model: K30 series (30mm³) [0.00183 in³], K31-K32-K33 series (40mm³) [0.00244 in³] • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi up to 400°C (750°F) • Stem material: 17-4 PH -

Features • Pressure ranges from: 0-17 ato 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FSO (H); < ±0.5% FSO (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. NaK is defined as a safe substance (GRAS). • Quantity of NaK contained per model: K70 series (30mm³) [0.00183 in³], K71, K72, K73 (40mm³) [0.00244 in³] • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100 bar-1500 psi up to 400°C (750°F) • Material of stem 17-4PH

Features • Pressure ranges from: 0-17 ato 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FSO (H); < ±0.5% FSO (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. NaK is defined as a safe substance (GRAS). • Quantity of NaK contained per model: K70 series (30mm³) [0.00183 in³], K71, K72, K73 (40mm³) [0.00244 in³] • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100 bar-1500 psi up to 400°C (750°F) • Material of stem 17-4PH -

Features • Pressure ranges from: 0-17 to 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FS (H); < ±0.5% FS (M) • SIL2 approvals for Functional Safety • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Stem drift Auto compensation function (SP version) • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100 bar-1500 psi up to 400°C (750°F) • Material of stem 17-4PH

Features • Pressure ranges from: 0-17 to 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FS (H); < ±0.5% FS (M) • SIL2 approvals for Functional Safety • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Stem drift Auto compensation function (SP version) • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100 bar-1500 psi up to 400°C (750°F) • Material of stem 17-4PH -

Features Electrical • Digital output signal with DP404 CAN OPEN communication protocol • Transmission frequency (Baud rate): 10 Kbaud to 1Mbaud (default 500 Kbaud) • Software selection of Baud rate and ID nodes • Operation with 1 or 2 settable alarm limits • “Autozero” for temperature compensation • 80% FSO calibration signal

Features Electrical • Digital output signal with DP404 CAN OPEN communication protocol • Transmission frequency (Baud rate): 10 Kbaud to 1Mbaud (default 500 Kbaud) • Software selection of Baud rate and ID nodes • Operation with 1 or 2 settable alarm limits • “Autozero” for temperature compensation • 80% FSO calibration signal -

Features • Pressure ranges from: 0-35 to 0-1000 bar / 0-500 to 0-15000 psi • Accuracy: < ±0.25% FSO (H); < ±0.5% FSO (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. NaK is defined as a safe substance (GRAS) • Quantity of NaK contained per model: KE0 series (30mm³) [0.00183 in³], KE1, KE2, KE3 (40mm³) [0.00244 in³] • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Stem drift Auto compensation function (SP version) • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi up to 400°C (750°F) • Stem material: 17-4 PH

Features • Pressure ranges from: 0-35 to 0-1000 bar / 0-500 to 0-15000 psi • Accuracy: < ±0.25% FSO (H); < ±0.5% FSO (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. NaK is defined as a safe substance (GRAS) • Quantity of NaK contained per model: KE0 series (30mm³) [0.00183 in³], KE1, KE2, KE3 (40mm³) [0.00244 in³] • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Stem drift Auto compensation function (SP version) • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi up to 400°C (750°F) • Stem material: 17-4 PH -

Features • Pressure ranges from: 0-17 to 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FSO (H); < ±0.5% FSO (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. NaK is defined as a safe substance (GRAS) • Quantity of NaK contained per model: KE0 series (30mm³) [0.00183 in³], KE1, KE2, KE3 (40mm³) [0.00244 in³] • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi up to 400°C (750°F) • Stem material: 17-4 PH

Features • Pressure ranges from: 0-17 to 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FSO (H); < ±0.5% FSO (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. NaK is defined as a safe substance (GRAS) • Quantity of NaK contained per model: KE0 series (30mm³) [0.00183 in³], KE1, KE2, KE3 (40mm³) [0.00244 in³] • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi up to 400°C (750°F) • Stem material: 17-4 PH -

Features • Pressure ranges from: 0-17 to 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FS (H); < ±0.5% FS (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. • SIL2 approvals for Functional Safety • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Stem drift Auto compensation function (SP version) • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi up to 400°C (750°F) • Stem material: 17-4 PH

Features • Pressure ranges from: 0-17 to 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FS (H); < ±0.5% FS (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. • SIL2 approvals for Functional Safety • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Stem drift Auto compensation function (SP version) • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi up to 400°C (750°F) • Stem material: 17-4 PH