- D91-PP 600 - 1600 l/h

- D91-PVDF 600 - 1600 l/h

- D92-PP 600 - 2200 l/h

- D92-PVDF 600 - 2200 l/h

- D93-PP 600 - 3300 l/h

- D93-PVDF 600 - 3300 l/h

- D94-PP 600 - 4400 l/h

- D94-PVDF 600 - 4400 l/h

- D95-PP 600 - 6000 l/h

- D95-PVDF 600 - 6000 l/h

-

D120 Series Family

D120 Series Family- D123-PP 900 - 2200 l/h

- D123-PVDF 900 - 2200 l/h

- D124-PP 900 - 4000 l/h

- D124-PVDF 900 - 4000 l/h

- D125-PP 900 - 7500 l/h

- D125-PVDF 900 - 7500 l/h

- D126-PP 900 - 9000 l/h

- D126-PVDF 900 - 9000 l/h

-

D13 Series Family

D13 Series Family- D13-08-300-PP 2000 - 8000 l/h

- D13-10-300-PP 2000 - 10000 l/h

- D13-12-300-PP 2000 - 12000 l/h

-

D16 Series Family

D16 Series Family- D16-05-260-SS 1700 - 5000 l/h

- D16-07-260-SS 1700 - 7000 l/h

- D16-14-400-SS 1700 - 13500 l/h

- D16-17-400-SS 1700 - 17000 l/h

- D16-21-400-SS 1700 - 21000 l/h

- D16-32-400-SS 1700 - 32000 l/h

-

D18 Series Family

D18 Series Family- D18-14-400-PP 12000 - 14000 l/h

- D18-14-400-PVDF 12000 - 23000 l/h

- D18-18-400-PP 12000 - 18000 l/h

- D18-18-400-PVDF 12000 - 18000 l/h

- D18-23-400-PP 12000 - 23000 l/h

- D18-23-400-PVDF 12000 - 23000 l/h

- D18-30-400-PP 12000 - 30000 l/h

- D18-30-400-PVDF 12000 - 30000 l/h

- D18-36-400-PP 12000 - 36000 l/h

- D18-36-400-PVDF 12000 - 36000 l/h

- D18-43-400-PP 12000 - 43000 l/h

- D18-43-400-PVDF 12000 - 43000 l/h

- D18-05-HD-400-PP Qmax 5000 l/h

- D18-05-HD-400-PVDF Qmax 5000 l/h

- D18-10-HD-400-PP Qmax 10000 l/h

-

D20 Series Family

D20 Series Family- D20-40/20-PP 20 - 40 m3/h

- D20-45/25-PP 20 - 45 m3/h

- D20-50/28-PP 20 - 50 m3/h

- D20-50/31-PP 20 - 54 m3/h

-

D24 Series Family

D24 Series Family- D24-50/27-PP 20 - 65 m3/h

- D24-55/35-PP 20 - 54 m3/h

- D24-60/29-PP 20 - 73 m3/h

- D24-60/42-PP 20 - 54 m3/h

- D24-65/37-PP 20 - 54 m3/h

- D24-70/42-PP 20 - 82 m3/h

-

M10 .. M15 Series Family

M10 .. M15 Series Family- M10-PP 120 - 1200 l/h

- M10-PVDF 120 - 1200 l/h

- M11-PP 120 - 2200 l/h

- M11-PP 120 - 2200 l/h

- M15-PP 120 - 4200 l/h

- M15-PVDF 120 - 1200 l/h

-

MX40 .. MX120 Series Family

MX40 .. MX120 Series Family- MX40-PP 2000 - 4200 l/h

- MX40-PVDF 2000 - 4200 l/h

- MX60-PP 2000 - 6000 l/h

- MX60-PVDF 2000 - 6000 l/h

- MX61-PP 2000 - 6000 l/h

- MX61-PVDF 2000 - 6000 l/h

- MX62-PP 2000 - 6000 l/h

- MX62-PVDF 2000 - 6000 l/h

- MX90-PP 2000 - 8200 l/h

- MX90-PVDF 2000 - 8200 l/h

- MX91-PP 2000 - 8200 l/h

- MX91-PVDF 2000 - 8200 l/h

- MX120-PP 2000 - 12000 l/h

- MX120-PVDF 2000 - 12000 l/h

-

M110 .. M400 Series Family

M110 .. M400 Series Family- M110-PP 10 - 11 m3/h

- M110-PVDF 10 - 11 m3/h

- M150-PP 10 - 18 m3/h

- M150-PVDF 10 - 18 m3/h

- M220-PP 10 - 24 m3/h

- M220-PVDF 10 - 24 m3/h

- M300-PP 10 - 26 m3/h

- M300-PVDF 10 - 26 m3/h

- M400-PP 10 - 30 m3/h

- M400-PVDF 10 - 30 m3/h

- M150-H-PP 10 - 12 m3/h

- M150-H-PVDF 10 - 12 m3/h

- M220-H-PP 10 - 16 m3/h

- M220-H-PVDF 10 - 16 m3/h

- M300-H-PP 10 - 20 m3/h

- M300-H-PVDF 10 - 20 m3/h

-

MX160...MX410 Series Family

MX160...MX410 Series Family- MX160-PP 10 - 16 m3/h

- MX210-PP 10 - 21 m3/h

- MX260-PP 10 - 26 m3/h

- MX350-PP 10 - 35 m3/h

- MX410-PP 10 - 38 m3/h

-

S55 .. S300 Series Family

S55 .. S300 Series Family- S55-PP 2000 - 6000 l/h

- S110-PP 2000 - 14000 l/h

- S150-PP 2000 - 18000 l/h

- S220-PP 10 - 24 m3/h

- S300-PP 10 - 32 m3/h

-

Filter media are used for filter pumps and filter chambers. We provide filter bags, filter discs, filter cartridges, and micro fibers. [ Click here for more details ]

Filter media are used for filter pumps and filter chambers. We provide filter bags, filter discs, filter cartridges, and micro fibers. [ Click here for more details ] -

Basket strainers are designed to protect pumps for large incoming particles. This can prevent serious damage of your pumps, and will therefore reduce maintenance cost and process down time. [ Click here for more details ]

Basket strainers are designed to protect pumps for large incoming particles. This can prevent serious damage of your pumps, and will therefore reduce maintenance cost and process down time. [ Click here for more details ] -

Priming chambers add a self-priming feature to a standard horizontal pump. A centrifugal pump by its principle is not self-priming, because of its limited ability to transport air. The priming chamber is initially filled with solution. The priming time depends on length/diameter of suction pipe. After the initial filling of the chamber, next time, the pump will automatically reprime. [ Click here for more details ]

Priming chambers add a self-priming feature to a standard horizontal pump. A centrifugal pump by its principle is not self-priming, because of its limited ability to transport air. The priming chamber is initially filled with solution. The priming time depends on length/diameter of suction pipe. After the initial filling of the chamber, next time, the pump will automatically reprime. [ Click here for more details ] -

Features

Features- Magnetic drive pump,

- 100% air tight

-

Features

Features- Very easy, leak free, in-tank installation

- Filter chamber with welded bottom (no seal)

- Filter media discs, cartridge or bag

- EPDM elastomers for PP and FPM for PVDF

- Including suction strainer

- Max. temperature PP 80°C, PVDF 100°C

- Stainless steel fittings, fasteners and type shields

- Air release

- High quality European, purpose designed electric motor: - 3 phase, 50/60 Hz, 2900/3500 rpm, IP55, multi voltage - with double layer 2C chemical resistant coating - full length SS shaft with PP/PVDF protection pipe - including PP drip cover, fan cover and wiring box - suitable for frequency drive control

-

Features

Features- Very easy, leak free, in-tank installation

- Filter chamber with welded bottom (no seal)

- Discs (thin/thick paper, cloth), cartridges or bags

- Including complete +GF+ union

- EPDM elastomers for PP and FPM for PVDF

- Including suction strainer

- Max. temperature PP 80°C, PVDF 100°C

- Stainless steel fittings, fasteners and type shields

- Pressure gauge and air release

- High quality European, purpose designed electric motor: - 3 phase, 50/60 Hz, 2900/3500 rpm, IP55, multi voltage - with double layer 2C chemical resistant coating - full length SS shaft with PP/PVDF protection pipe - including PP drip cover, fan cover and wiring box - suitable for frequency drive control

-

Features

Features- Full PP construction from machined Simona® AlphaPlusTM PP

- Hinged cover from reinforced PP-GF pressed plate

- Stainless steel ANSI316 forged swing bolt closure

- High wall thickness cylinder with welded bottom (no seal)

- Smart pump pull back system for easy maintenance

- Stainless steel fittings, fasteners and type shields

- Including complete +GF+ three-piece union

- EPDM elastomers

- Max. temperature 80°C

- Pressure gauge, air release and drain valve

- Thermal overload incl. on/off switch and lead

- Magnetic drive or mechanical seal pump

- High quality European, purpose designed electric motor: - 3 phase, 50/60 Hz, 2900/3500 rpm, IP55, multi voltage - with double layer 2C chemical resistant coating - suitable for frequency drive control

-

Features

Features- Full PP construction from machined Simona® AlphaPlusTM PP

- Hinged cover from reinforced PP-GF pressed plate

- Stainless steel ANSI316 forged swing bolt closure

- High wall thickness cylinder with welded bottom (no seal)

- Smart pump pull back system for easy maintenance

- Stainless steel fittings, fasteners and type shields

- Including complete +GF+ three-piece union

- EPDM elastomers

- Max. temperature 80°C

- Pressure gauge, air release and drain valve

- Thermal overload incl. on/off switch and lead

- Magnetic drive or mechanical seal pump

- High quality European, purpose designed electric motor: - 3 phase, 50/60 Hz, 2900/3500 rpm, IP55, multi voltage - with double layer 2C chemical resistant coating - suitable for frequency drive control

-

Features

Features- Filter chamber with welded bottom (no seal)

- Machined from Simona® AlphaPlusTM high performance PP

- Top plate made of glass-filled PP

- Including complete +GF+ union ends

- EPDM elastomers

- Cartridges

- Max. temperature PP 80°C

- Stainless steel fittings, fasteners and type shields

- Pressure gauge and air release

-

Features

Features- Filter chamber with welded bottom (no seal)

- Machined from Simona® AlphaPlusTM high performance PP

- Including complete +GF+ union ends

- EPDM elastomers

- Thin discs (large filter area) or thick discs (large dirt holding capacity)

- Filter paper (thin/thick), cloth, cartridges (max. Ø 70mm) or bags

- Discs can be removed in manageable stacks

- Max. temperature PP 80°C

- Stainless steel fittings, fasteners and type shields

- Hinged cover for easy access

- Pressure gauge and air release

-

HE-FSD Family Series

HE-FSD Family Series- HE-FSD-72-HT-S110

- HE-FSD-152-HT-S220

- HE-FSD-153-HT-S300

-

HRC Family Series

HRC Family Series- HRC-3000

- HRC-6000

-

Technical Specifications

Technical Specifications- Skid: ANSI 316 frame on adjustable feet

- Material: PP with EPDM elastomers

- Temperature: 80°C max.

- Pump: Magnetic Drive MXH150-PP, 1450 rpm, 0,55 kW motor

- Filter, Main: 95 off Horizontal Disc ø 295 mm, volume 28 liter, pressure gauge 0-1,0 bar

- Slurry tank: volume 80 liter, inspection glass to check clarity

-

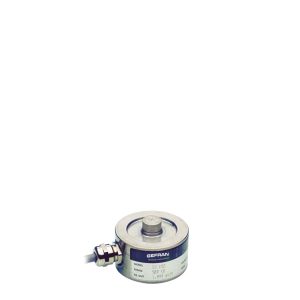

Features • Ranges: from 1 to 1000 bar • Nominal Output Signal: 4...20mA (2 wires) 0...10Vdc / 0.1...5.1Vdc / 0.1...10.1Vdc / 0...5Vdc / 1...5Vdc / 1...6Vdc / 1...10Vdc / 0.2...10.2Vdc (3 wires) 0.5...4.5Vdc (3 wires - ratiometric) • Compact size • Wetted parts: Stainless steel • SIL 2 certified according to IEC/EN 62061:2005

Features • Ranges: from 1 to 1000 bar • Nominal Output Signal: 4...20mA (2 wires) 0...10Vdc / 0.1...5.1Vdc / 0.1...10.1Vdc / 0...5Vdc / 1...5Vdc / 1...6Vdc / 1...10Vdc / 0.2...10.2Vdc (3 wires) 0.5...4.5Vdc (3 wires - ratiometric) • Compact size • Wetted parts: Stainless steel • SIL 2 certified according to IEC/EN 62061:2005 -

Features • Ranges: from 0...3 to 0...1000 bar and ranges from -1...+1 to -1...+10 bar • Output signal 4...20mA 2-wires / 0.1...5.1Vdc /0.1...10.1Vdc / 0...5Vdc / 0...10Vdc / 1...5Vdc / 1...10Vdc • Protection rating: IP65/IP67 • Wetted parts AISI 430F and 17-4PH • Available with a variety of process connections, both standard and custom

Features • Ranges: from 0...3 to 0...1000 bar and ranges from -1...+1 to -1...+10 bar • Output signal 4...20mA 2-wires / 0.1...5.1Vdc /0.1...10.1Vdc / 0...5Vdc / 0...10Vdc / 1...5Vdc / 1...10Vdc • Protection rating: IP65/IP67 • Wetted parts AISI 430F and 17-4PH • Available with a variety of process connections, both standard and custom -

Features • Ranges: from 0...0.05 bar to 0...60 bar (0...1 to 0...1000 psi) • Complete range of voltage/current outputs • Protection rating: IP65/IP67 • Wetted parts: AISI316L • Operating temperature range -40...+85°C • Accuracy: ± 0.15% FS typical • Fill Fluid: silicone oil • Available absolute ranges • Available “Barometric” range (0.8-1.2 bar abs) • Available low ranges (50mbar and 100mbar)

Features • Ranges: from 0...0.05 bar to 0...60 bar (0...1 to 0...1000 psi) • Complete range of voltage/current outputs • Protection rating: IP65/IP67 • Wetted parts: AISI316L • Operating temperature range -40...+85°C • Accuracy: ± 0.15% FS typical • Fill Fluid: silicone oil • Available absolute ranges • Available “Barometric” range (0.8-1.2 bar abs) • Available low ranges (50mbar and 100mbar) -

Features • Ranges: from: 0...1000 to 0...5000 bar • Output signal 4...20mA 2 wires / 0,1...5,1Vdc / 0.1...10.1Vdc / 0...5Vdc / 0...10Vdc / 1...5Vdc / 1...6Vdc / 1...10Vdc • Protection: IP65/IP67 • Wetted parts: 15-5PH / 17-4PH stainless steel • Measurement diaphragm with monolithic stainless steel structure • Digital Auto-Zero & Span function • Suitable for measuring static and dynamic pressure *

Features • Ranges: from: 0...1000 to 0...5000 bar • Output signal 4...20mA 2 wires / 0,1...5,1Vdc / 0.1...10.1Vdc / 0...5Vdc / 0...10Vdc / 1...5Vdc / 1...6Vdc / 1...10Vdc • Protection: IP65/IP67 • Wetted parts: 15-5PH / 17-4PH stainless steel • Measurement diaphragm with monolithic stainless steel structure • Digital Auto-Zero & Span function • Suitable for measuring static and dynamic pressure * -

Features • Ranges: from 0...10 to 0...1000 bar • Output signal 4...20mA 2-wires / 0.1...5.1Vdc / 0.1...10.1Vdc / 0...5Vdc / 0...10Vdc / 1...5Vdc / 1...6Vdc / 1...10Vdc • Protection rating: IP65/IP67 • Wetted parts: 17-4PH Stainless Steel • Flush fitting stainless steel measuring diaphragm • Digital Autozero & Span function

Features • Ranges: from 0...10 to 0...1000 bar • Output signal 4...20mA 2-wires / 0.1...5.1Vdc / 0.1...10.1Vdc / 0...5Vdc / 0...10Vdc / 1...5Vdc / 1...6Vdc / 1...10Vdc • Protection rating: IP65/IP67 • Wetted parts: 17-4PH Stainless Steel • Flush fitting stainless steel measuring diaphragm • Digital Autozero & Span function -

Features • Ranges: from 0...25 to 0...600 bar • Output signal 4...20mA 2-wires / 0.1...5.1Vdc / 0.1...10.1Vdc / 0...5Vdc / 0...10Vdc / 1...5Vdc / 1...6Vdc / 1...10Vdc • Protection rating: IP65/IP67 • Wetted parts: 17-4PH Stainless Steel • Miniature flush fitting stainless steel measuring diaphragm • Magnetic or External Autozero function

Features • Ranges: from 0...25 to 0...600 bar • Output signal 4...20mA 2-wires / 0.1...5.1Vdc / 0.1...10.1Vdc / 0...5Vdc / 0...10Vdc / 1...5Vdc / 1...6Vdc / 1...10Vdc • Protection rating: IP65/IP67 • Wetted parts: 17-4PH Stainless Steel • Miniature flush fitting stainless steel measuring diaphragm • Magnetic or External Autozero function -

Features • Ranges: from 0...3 to 0...1000 bar and ranges from -1...+1 to -1...+10 bar • Output signal 4...20mA 2-wires / 0.1...5.1Vdc /0.1...10.1Vdc / 0...5Vdc / 0...10Vdc / 1...5Vdc / 1...10Vdc • Protection rating: IP65/IP67 • Wetted parts AISI 430F and 17-4PH • Available with a variety of process connections, both standard and custom

Features • Ranges: from 0...3 to 0...1000 bar and ranges from -1...+1 to -1...+10 bar • Output signal 4...20mA 2-wires / 0.1...5.1Vdc /0.1...10.1Vdc / 0...5Vdc / 0...10Vdc / 1...5Vdc / 1...10Vdc • Protection rating: IP65/IP67 • Wetted parts AISI 430F and 17-4PH • Available with a variety of process connections, both standard and custom -

Features The M92 is a melt pressure and temperature monitoring system which comes complete with the following items: • M32-6-M-xxxx-1-4-D-000 (melt pressure transducer with type “J” thermocouple) • 40TB-10-RRR-2-0-1 (1/4 DIN pressure and temperature indicator) • C08WLS (25 foot 6-pin cable) • SF18 (mounting bracket)

Features The M92 is a melt pressure and temperature monitoring system which comes complete with the following items: • M32-6-M-xxxx-1-4-D-000 (melt pressure transducer with type “J” thermocouple) • 40TB-10-RRR-2-0-1 (1/4 DIN pressure and temperature indicator) • C08WLS (25 foot 6-pin cable) • SF18 (mounting bracket) -

Features The W92 is a melt pressure and temperature monitoring system which comes complete with the following items: • W32-6-M-xxxx-1-4-D-000 (oil-filled melt pressure transducer with type “J” thermocouple) • 40TB-10-RRR-2-0-1 (1/4 DIN pressure and temperature indicator) • C08WLS (25 foot 6-pin cable) • SF18 (mounting bracket)

Features The W92 is a melt pressure and temperature monitoring system which comes complete with the following items: • W32-6-M-xxxx-1-4-D-000 (oil-filled melt pressure transducer with type “J” thermocouple) • 40TB-10-RRR-2-0-1 (1/4 DIN pressure and temperature indicator) • C08WLS (25 foot 6-pin cable) • SF18 (mounting bracket) -

Features • Small press-on sensor with one-hole mounting • Direct measurement of surface strain • Without amplifier (passiv) • High accuracy and linearity in tension and pressure (like bonded strain gauges) • For dynamic applications • Used on presses, injection moulding and die-casting machines • Quick and easy mounting • Protected against overload • Optional accessories: - Signal amplifier VDA - Monitor DU-1D

Features • Small press-on sensor with one-hole mounting • Direct measurement of surface strain • Without amplifier (passiv) • High accuracy and linearity in tension and pressure (like bonded strain gauges) • For dynamic applications • Used on presses, injection moulding and die-casting machines • Quick and easy mounting • Protected against overload • Optional accessories: - Signal amplifier VDA - Monitor DU-1D -

Features • Direct measurement of surface strain • With high grade variable digital amplifier • Amplifies the signal on the spot, avoiding EMC problems • High accuracy and linearity in tension and pressure (like bonded strain gauges) • For dynamic applications • Used on presses, injection moulding and die-casting machines • Quick and easy mounting • Protected against overload

Features • Direct measurement of surface strain • With high grade variable digital amplifier • Amplifies the signal on the spot, avoiding EMC problems • High accuracy and linearity in tension and pressure (like bonded strain gauges) • For dynamic applications • Used on presses, injection moulding and die-casting machines • Quick and easy mounting • Protected against overload -

Features • Measure strain in deep holes • With calibrated digital amplifier • Quick and easy mounting with torque-wrench • High linearity on tension and compression • For dynamic applications • Used in injection moulding and die-casting machines or any cylinder • Very high accuracy (like bonded strain gauges) • Protected against overload

Features • Measure strain in deep holes • With calibrated digital amplifier • Quick and easy mounting with torque-wrench • High linearity on tension and compression • For dynamic applications • Used in injection moulding and die-casting machines or any cylinder • Very high accuracy (like bonded strain gauges) • Protected against overload -

Features • Direct measurement of surface strain • With integrated digital amplifier • Quick and easy non-destructive assembly • High accuracy and linearity • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…250mm) • Dynamic applications • Ideal for online monitoring of clamping force

Features • Direct measurement of surface strain • With integrated digital amplifier • Quick and easy non-destructive assembly • High accuracy and linearity • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…250mm) • Dynamic applications • Ideal for online monitoring of clamping force -

Features • Direct measurement of surface strain • Quick and easy non-destructive assembly • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…400mm) • Dynamic applications • Without amplifier (passive) • Ideal for online monitoring of clamping force • Ideal for self-made load cells

Features • Direct measurement of surface strain • Quick and easy non-destructive assembly • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…400mm) • Dynamic applications • Without amplifier (passive) • Ideal for online monitoring of clamping force • Ideal for self-made load cells -

Features • Direct measurement of surface strain • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • Without amplifier (passive)

Features • Direct measurement of surface strain • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • Without amplifier (passive) -

Features • Measurement of nozzle touch force (nozzle pressure force) in injection-molding and die-casting machines • User-friendly, small and compact • Force measurement range: 200kN / 450kN • Very high repeatability • Direct connection to our signal amplifiers and monitors • Various nozzle adapters can be retrofitted (e.g., brass) • Magnetic bases can be retrofitted in different sizes

Features • Measurement of nozzle touch force (nozzle pressure force) in injection-molding and die-casting machines • User-friendly, small and compact • Force measurement range: 200kN / 450kN • Very high repeatability • Direct connection to our signal amplifiers and monitors • Various nozzle adapters can be retrofitted (e.g., brass) • Magnetic bases can be retrofitted in different sizes -

Features • Measure strain in any direction in seconds • Smallest press-on sensor with magnet mounting • Direct surface strain reading like bonded strain gages, high linearity on tension and compression • Quick and easy mounting on magnetic structures • Calibrated sensor (K=2.00) for dynamic applications • Ideal for checking FEM calculations and for stress analysis on flat steel structures • Without amplifier (passiv) • External amplifier recommended (e.g. MBA100; VDA, Monitor DU-1D

Features • Measure strain in any direction in seconds • Smallest press-on sensor with magnet mounting • Direct surface strain reading like bonded strain gages, high linearity on tension and compression • Quick and easy mounting on magnetic structures • Calibrated sensor (K=2.00) for dynamic applications • Ideal for checking FEM calculations and for stress analysis on flat steel structures • Without amplifier (passiv) • External amplifier recommended (e.g. MBA100; VDA, Monitor DU-1D -

Features • Complete system for the strain-measurement on one tie bar • Direct display of strain values in µe, kN or t • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 1- channel digital monitor DU1D • Battery operation possible (optional) / not rechargeable • Very compact and easy to use system

Features • Complete system for the strain-measurement on one tie bar • Direct display of strain values in µe, kN or t • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 1- channel digital monitor DU1D • Battery operation possible (optional) / not rechargeable • Very compact and easy to use system -

Features • Complete system for the simultaneous strain-measurement on up to four tie bars • Direct display of strain values in µe, kN or t • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 4- channel digital monitor DU4D • USB connection for tie bar adjustment software (optional) • Very compact and easy to use system

Features • Complete system for the simultaneous strain-measurement on up to four tie bars • Direct display of strain values in µe, kN or t • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 4- channel digital monitor DU4D • USB connection for tie bar adjustment software (optional) • Very compact and easy to use system -

Features • Complete system for the simultaneous strain-measurement on up to four tie bars • Direct display of strain values in µe, kN or t (via our Inspectmate software) • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 4- channel digital monitor-box DU-4USB • USB connection for tie bar adjustment software and power supply • Very compact and easy to use system

Features • Complete system for the simultaneous strain-measurement on up to four tie bars • Direct display of strain values in µe, kN or t (via our Inspectmate software) • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 4- channel digital monitor-box DU-4USB • USB connection for tie bar adjustment software and power supply • Very compact and easy to use system -

Features • Complete system for the strain-measurement on one tie bar • Direct display of the measured values in µe, kN or t • Quick and easy non-destructive assembly • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…400mm) • Dynamic applications • 1- channel digital monitor DU1D • Ideal for self-construction load cells • Very compact and easy to use system

Features • Complete system for the strain-measurement on one tie bar • Direct display of the measured values in µe, kN or t • Quick and easy non-destructive assembly • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…400mm) • Dynamic applications • 1- channel digital monitor DU1D • Ideal for self-construction load cells • Very compact and easy to use system -

Features • Complete system for the simultaneous strain-measurement on up to four tie bars • Direct display of the measured values in µe, kN or t • Quick and easy non-destructive assembly • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…400mm) • Dynamic applications • 4- channel digital monitor DU4D • USB connection for tie bar adjustment software (optional) • Analog output 0...10VDC (optional) • Very compact and easy to use system

Features • Complete system for the simultaneous strain-measurement on up to four tie bars • Direct display of the measured values in µe, kN or t • Quick and easy non-destructive assembly • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • One system for many different tie bar diameters (25…400mm) • Dynamic applications • 4- channel digital monitor DU4D • USB connection for tie bar adjustment software (optional) • Analog output 0...10VDC (optional) • Very compact and easy to use system -

Features • Available for all Sensormate sensors (2/4 bridges) • Direct display of the measured values in µe, kN or t • High accuracy and stable reset • Automatic reset, external reset and alarm output • Ideal for control cabinet installation (96x96mm, DIN 43700) • Battery operation possible (optional) / not rechargeable

Features • Available for all Sensormate sensors (2/4 bridges) • Direct display of the measured values in µe, kN or t • High accuracy and stable reset • Automatic reset, external reset and alarm output • Ideal for control cabinet installation (96x96mm, DIN 43700) • Battery operation possible (optional) / not rechargeable -

Features • Available for all Sensormate sensors (2/4 bridges) • Direct display of the measured values in µe, kN or t • High accuracy and stable reset • Very bright displays and robust aluminum housing (IP52); Ideal for rough environments • USB connection for tie bar adjustment software (optional) • Analog output 0...10VDC (optional)

Features • Available for all Sensormate sensors (2/4 bridges) • Direct display of the measured values in µe, kN or t • High accuracy and stable reset • Very bright displays and robust aluminum housing (IP52); Ideal for rough environments • USB connection for tie bar adjustment software (optional) • Analog output 0...10VDC (optional)