-

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element and PVDF screw plug reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element and PVDF screw plug reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element and PVDF screw plug reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element and PVDF screw plug reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Optional patented purge feature promotes a longer heater life by reducing chemical permeation • Lower Watt densities available for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Optional patented purge feature promotes a longer heater life by reducing chemical permeation • Lower Watt densities available for highly viscous solutions & technical acids -

Features • Years of trouble-free performance in the most demanding chemical applications, such as semiconductor, FPD, MEMS, & biomedical industries • PTFE heater element with 38mm (.015 in.) thick fluoropolymer sheath for safety & long service life • Patented “purged” element design ensures maximum element life by removing chemical • permeation • 100% fluoropolymer wetted surfaces for virtually any non-flammable process solutions including HF & KOH • Low Watt density design promotes process temperature uniformity

Features • Years of trouble-free performance in the most demanding chemical applications, such as semiconductor, FPD, MEMS, & biomedical industries • PTFE heater element with 38mm (.015 in.) thick fluoropolymer sheath for safety & long service life • Patented “purged” element design ensures maximum element life by removing chemical • permeation • 100% fluoropolymer wetted surfaces for virtually any non-flammable process solutions including HF & KOH • Low Watt density design promotes process temperature uniformity -

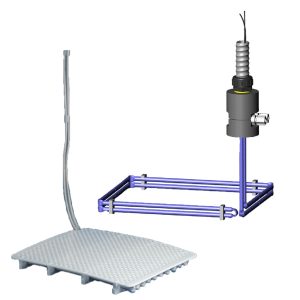

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density Design of 10 W/in2 (1.5 W/cm2) • Flexible riser with 4 ft. (1.2m) of continuous PTFE cable leading to vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes a longer heater life by reducing chemical permeation

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density Design of 10 W/in2 (1.5 W/cm2) • Flexible riser with 4 ft. (1.2m) of continuous PTFE cable leading to vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes a longer heater life by reducing chemical permeation -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Flexible riser with 4 ft. (1.2m) of continuous PTFE cable leading to vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes a longer heater life by reducing chemical permeation

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Flexible riser with 4 ft. (1.2m) of continuous PTFE cable leading to vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes a longer heater life by reducing chemical permeation -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Flexible riser with 4 ft. (1.2m) of continuous PTFE cable leading to vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes a longer heater life by reducing chemical permeation

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Flexible riser with 4 ft. (1.2m) of continuous PTFE cable leading to vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes a longer heater life by reducing chemical permeation -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower watt densities for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower watt densities for highly viscous solutions & technical acids -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit. • Lower watt densities for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit. • Lower watt densities for highly viscous solutions & technical acids -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Optional patented purge feature promotes longer heater life • Lower Watt densities available for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Optional patented purge feature promotes longer heater life • Lower Watt densities available for highly viscous solutions & technical acids -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life