-

Features • ½-inch (13mm) PFA tubing, .030” (.76mm) thick • All welded construction (shell) • 4½-inch (114mm) diameter polypropylene or PVDF shell • Internally baffled for enhanced heat exchanger performance • “U” factor (depending on flow rate): 25-50 BTU/(hr. x ft² x °F) = 142-284 J/(s x m² x °C) • Shell-side drain connection

Features • ½-inch (13mm) PFA tubing, .030” (.76mm) thick • All welded construction (shell) • 4½-inch (114mm) diameter polypropylene or PVDF shell • Internally baffled for enhanced heat exchanger performance • “U” factor (depending on flow rate): 25-50 BTU/(hr. x ft² x °F) = 142-284 J/(s x m² x °C) • Shell-side drain connection -

Features • Wide variety of materials available for use in heating or cooling applications for alkaline or acid solutionsand rinse tanks. Check solution guide or consult with your chemical supplier for proper sheath material • Heavy wall, 18 gauge metal tubing available in steel, 316 stainless steel and titanium • 1” diameter tubing and 1” MNPT connection fittings standard • Single point connections reduce the potential for leaks and simplify installation • Tubing sizes: ⅜ inch diameter through 1¼ inch diameter • Helical sizes: From 3¼ inch to 10 ft. diameter available based on tube diameter and wall thickness • Wall thickness: .035 through .065 inches

Features • Wide variety of materials available for use in heating or cooling applications for alkaline or acid solutionsand rinse tanks. Check solution guide or consult with your chemical supplier for proper sheath material • Heavy wall, 18 gauge metal tubing available in steel, 316 stainless steel and titanium • 1” diameter tubing and 1” MNPT connection fittings standard • Single point connections reduce the potential for leaks and simplify installation • Tubing sizes: ⅜ inch diameter through 1¼ inch diameter • Helical sizes: From 3¼ inch to 10 ft. diameter available based on tube diameter and wall thickness • Wall thickness: .035 through .065 inches -

Features • Wide variety of materials available for use in heating or cooling applications for alkaline or acid solutions and rinse tanks. Check solution guide or consult with • your chemical supplier for proper sheath material. • Heavy wall, 20 gauge metal tubing available in steel, 316 stainless steel and titanium. • 1” diameter tubing and 1” MNPT connection fittings standard. • 4.6 square foot to 89.9 square foot of exchange area • Single point connections reduce the potential for leaks and simplify installation

Features • Wide variety of materials available for use in heating or cooling applications for alkaline or acid solutions and rinse tanks. Check solution guide or consult with • your chemical supplier for proper sheath material. • Heavy wall, 20 gauge metal tubing available in steel, 316 stainless steel and titanium. • 1” diameter tubing and 1” MNPT connection fittings standard. • 4.6 square foot to 89.9 square foot of exchange area • Single point connections reduce the potential for leaks and simplify installation -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element and PVDF screw plug reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element and PVDF screw plug reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element and PVDF screw plug reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element and PVDF screw plug reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Optional patented purge feature promotes a longer heater life by reducing chemical permeation • Lower Watt densities available for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Optional patented purge feature promotes a longer heater life by reducing chemical permeation • Lower Watt densities available for highly viscous solutions & technical acids -

Features • Years of trouble-free performance in the most demanding chemical applications, such as semiconductor, FPD, MEMS, & biomedical industries • PTFE heater element with 38mm (.015 in.) thick fluoropolymer sheath for safety & long service life • Patented “purged” element design ensures maximum element life by removing chemical • permeation • 100% fluoropolymer wetted surfaces for virtually any non-flammable process solutions including HF & KOH • Low Watt density design promotes process temperature uniformity

Features • Years of trouble-free performance in the most demanding chemical applications, such as semiconductor, FPD, MEMS, & biomedical industries • PTFE heater element with 38mm (.015 in.) thick fluoropolymer sheath for safety & long service life • Patented “purged” element design ensures maximum element life by removing chemical • permeation • 100% fluoropolymer wetted surfaces for virtually any non-flammable process solutions including HF & KOH • Low Watt density design promotes process temperature uniformity -

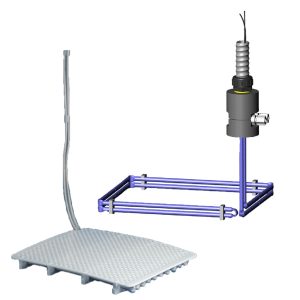

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density Design of 10 W/in2 (1.5 W/cm2) • Flexible riser with 4 ft. (1.2m) of continuous PTFE cable leading to vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes a longer heater life by reducing chemical permeation

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density Design of 10 W/in2 (1.5 W/cm2) • Flexible riser with 4 ft. (1.2m) of continuous PTFE cable leading to vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes a longer heater life by reducing chemical permeation -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Flexible riser with 4 ft. (1.2m) of continuous PTFE cable leading to vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes a longer heater life by reducing chemical permeation

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Flexible riser with 4 ft. (1.2m) of continuous PTFE cable leading to vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes a longer heater life by reducing chemical permeation -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Flexible riser with 4 ft. (1.2m) of continuous PTFE cable leading to vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes a longer heater life by reducing chemical permeation

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Flexible riser with 4 ft. (1.2m) of continuous PTFE cable leading to vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes a longer heater life by reducing chemical permeation -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower watt densities for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower watt densities for highly viscous solutions & technical acids -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit. • Lower watt densities for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit. • Lower watt densities for highly viscous solutions & technical acids -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Optional patented purge feature promotes longer heater life • Lower Watt densities available for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Optional patented purge feature promotes longer heater life • Lower Watt densities available for highly viscous solutions & technical acids -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life