-

Features • Operator interface with large LCD Display and three configurable bargraphs • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 32 function block applications • 8 Math application blocks • Timer, setpoint and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • 2 setpoint programmers (192 steps in 16 programs, or 12 programs with 16 fixed steps each) • 1 ingresso analogico lineare configurabile per funzioni ausiliarie • 2 PID control loops • 2 Programmatori di setpoint (192 passi in 16 programmi oppure 12 programmi da 16 passi fissi ciascuno) • Relay, logic, isolated analog outputs • Up to two TA inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU slave • RS485 serial communication in Modbus RTU master for reading/ writing information to Modbus slave devices • Ethernet Modbus TCP communication in Slave mode • Web server for browser access to web pages residing in the devvice, for monitoring and setting parameters • Bridge function for creation of Modbus RTU 485 sub-network • Weekly clock\calendar with RTC • Removable faceplate for immediate replacement • Accuracy 0,1%, sampling time 60 ms

Features • Operator interface with large LCD Display and three configurable bargraphs • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 32 function block applications • 8 Math application blocks • Timer, setpoint and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • 2 setpoint programmers (192 steps in 16 programs, or 12 programs with 16 fixed steps each) • 1 ingresso analogico lineare configurabile per funzioni ausiliarie • 2 PID control loops • 2 Programmatori di setpoint (192 passi in 16 programmi oppure 12 programmi da 16 passi fissi ciascuno) • Relay, logic, isolated analog outputs • Up to two TA inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU slave • RS485 serial communication in Modbus RTU master for reading/ writing information to Modbus slave devices • Ethernet Modbus TCP communication in Slave mode • Web server for browser access to web pages residing in the devvice, for monitoring and setting parameters • Bridge function for creation of Modbus RTU 485 sub-network • Weekly clock\calendar with RTC • Removable faceplate for immediate replacement • Accuracy 0,1%, sampling time 60 ms -

Features • Operator interface with large LCD Display, customizable, with choice of colors • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/ paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 16 function block applications • Timer, setpoint and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • Universal input configurable for thermocouples, resistance thermometers, linear inputs • Remote setpoint input • Relay, logic, isolated analog outputs • Up to two CT inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU • Removable faceplate for immediate replacement • Sampling time 60 ms

Features • Operator interface with large LCD Display, customizable, with choice of colors • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/ paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 16 function block applications • Timer, setpoint and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • Universal input configurable for thermocouples, resistance thermometers, linear inputs • Remote setpoint input • Relay, logic, isolated analog outputs • Up to two CT inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU • Removable faceplate for immediate replacement • Sampling time 60 ms -

Features • Operator interface with color touch screen display, 7” • Up to 16 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 250 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection

Features • Operator interface with color touch screen display, 7” • Up to 16 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 250 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection -

Features • Operator interface with color touch screen display, 3.5 “ • Up to 8 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 200 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Management of active and historic alarms • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection

Features • Operator interface with color touch screen display, 3.5 “ • Up to 8 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 200 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Management of active and historic alarms • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection -

Features • Universal input configurable from the faceplate • Acquisition of the input signal every 120msec ; resolution 30000steps • Two control outputs: relay, logic or analogue with Open/Close valve function • 3 configurable alarms • 2 analogue outputs (retransmission) • 2 digital inputs with configurable function • Auxiliary input for valve position potentiometer feedback • Heater Break or shortcircuit probe alarm • Self and Auto-tuning, Soft-start, Local/Remote setpoint, Auto/Man • Multiset function, timer set ramp

Features • Universal input configurable from the faceplate • Acquisition of the input signal every 120msec ; resolution 30000steps • Two control outputs: relay, logic or analogue with Open/Close valve function • 3 configurable alarms • 2 analogue outputs (retransmission) • 2 digital inputs with configurable function • Auxiliary input for valve position potentiometer feedback • Heater Break or shortcircuit probe alarm • Self and Auto-tuning, Soft-start, Local/Remote setpoint, Auto/Man • Multiset function, timer set ramp -

Features • Up to 16 inputs/16 outputs • For Temperature, Pressure, Flow, Level, RH, Conductivity, etc. • Various Input (X)/Output (Y) combinations : X4Y0, X4Y8, X8Y4, X8Y16, X16Y16, etc • Universal Input : 8 Thermocouples, Pt100, mV or mA input front panel selection without DIP for each channel • Front panel user calibration • Input burn protection • Non-volatile memory for parameters - no batteries • 3 key, 5 level programming • Setpoint and level locks • Tactile membrane keypad • 5 software versions : Indicator, Multisetpoint, Grouping, etc • RS485 with MODBUS RTU • Powerful, flexible SCADA software available • FDA21CFR Part11 compliant SCADA version also • Option : Printer interface (no computer needed) • 85~265 V AC SMPS or 24 V DC supply

Features • Up to 16 inputs/16 outputs • For Temperature, Pressure, Flow, Level, RH, Conductivity, etc. • Various Input (X)/Output (Y) combinations : X4Y0, X4Y8, X8Y4, X8Y16, X16Y16, etc • Universal Input : 8 Thermocouples, Pt100, mV or mA input front panel selection without DIP for each channel • Front panel user calibration • Input burn protection • Non-volatile memory for parameters - no batteries • 3 key, 5 level programming • Setpoint and level locks • Tactile membrane keypad • 5 software versions : Indicator, Multisetpoint, Grouping, etc • RS485 with MODBUS RTU • Powerful, flexible SCADA software available • FDA21CFR Part11 compliant SCADA version also • Option : Printer interface (no computer needed) • 85~265 V AC SMPS or 24 V DC supply -

Features • Upto 16 inputs/16 outputs • For Temperature, Pressure, Flow, Level, RH, Conductivity, etc. • Various Input (X)/Output (Y) combinations : X4Y0, X4Y8, X8Y4, X8Y16, X16Y16, etc • Universal Input : 8 Thermocouples, Pt100, mV or mA input front panel selection without DIP for each channel • Front panel user calibration • Input burn protection • Non-volatile memory for parameters - no batteries • 3 key, 5 level programming • Setpoint and level locks • Tactile membrane keypad • 5 software versions : Indicator, Multisetpoint, Grouping, etc • RS485 with MODBUS RTU • Powerful, flexible SCADA software available • FDA21CFR Part11 compliant SCADA version also • Option : Printer interface (no computer needed) • 85~265 V AC SMPS or 24 V DC supply

Features • Upto 16 inputs/16 outputs • For Temperature, Pressure, Flow, Level, RH, Conductivity, etc. • Various Input (X)/Output (Y) combinations : X4Y0, X4Y8, X8Y4, X8Y16, X16Y16, etc • Universal Input : 8 Thermocouples, Pt100, mV or mA input front panel selection without DIP for each channel • Front panel user calibration • Input burn protection • Non-volatile memory for parameters - no batteries • 3 key, 5 level programming • Setpoint and level locks • Tactile membrane keypad • 5 software versions : Indicator, Multisetpoint, Grouping, etc • RS485 with MODBUS RTU • Powerful, flexible SCADA software available • FDA21CFR Part11 compliant SCADA version also • Option : Printer interface (no computer needed) • 85~265 V AC SMPS or 24 V DC supply -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Optional patented purge feature promotes longer heater life • Lower Watt densities available for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Optional patented purge feature promotes longer heater life • Lower Watt densities available for highly viscous solutions & technical acids -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit. • Lower watt densities for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit. • Lower watt densities for highly viscous solutions & technical acids -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower watt densities for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower watt densities for highly viscous solutions & technical acids -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Flexible riser with 4 ft. (1.2m) of continuous PTFE cable leading to vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes a longer heater life by reducing chemical permeation

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Flexible riser with 4 ft. (1.2m) of continuous PTFE cable leading to vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes a longer heater life by reducing chemical permeation -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Flexible riser with 4 ft. (1.2m) of continuous PTFE cable leading to vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes a longer heater life by reducing chemical permeation

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Flexible riser with 4 ft. (1.2m) of continuous PTFE cable leading to vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes a longer heater life by reducing chemical permeation -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes longer heater life -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density Design of 10 W/in2 (1.5 W/cm2) • Flexible riser with 4 ft. (1.2m) of continuous PTFE cable leading to vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes a longer heater life by reducing chemical permeation

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density Design of 10 W/in2 (1.5 W/cm2) • Flexible riser with 4 ft. (1.2m) of continuous PTFE cable leading to vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids • Optional patented purge feature promotes a longer heater life by reducing chemical permeation -

Features • Years of trouble-free performance in the most demanding chemical applications, such as semiconductor, FPD, MEMS, & biomedical industries • PTFE heater element with 38mm (.015 in.) thick fluoropolymer sheath for safety & long service life • Patented “purged” element design ensures maximum element life by removing chemical • permeation • 100% fluoropolymer wetted surfaces for virtually any non-flammable process solutions including HF & KOH • Low Watt density design promotes process temperature uniformity

Features • Years of trouble-free performance in the most demanding chemical applications, such as semiconductor, FPD, MEMS, & biomedical industries • PTFE heater element with 38mm (.015 in.) thick fluoropolymer sheath for safety & long service life • Patented “purged” element design ensures maximum element life by removing chemical • permeation • 100% fluoropolymer wetted surfaces for virtually any non-flammable process solutions including HF & KOH • Low Watt density design promotes process temperature uniformity -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Optional patented purge feature promotes a longer heater life by reducing chemical permeation • Lower Watt densities available for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Optional patented purge feature promotes a longer heater life by reducing chemical permeation • Lower Watt densities available for highly viscous solutions & technical acids -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element and PVDF screw plug reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element and PVDF screw plug reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element and PVDF screw plug reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element and PVDF screw plug reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids -

Features • Wide variety of materials available for use in heating or cooling applications for alkaline or acid solutions and rinse tanks. Check solution guide or consult with • your chemical supplier for proper sheath material. • Heavy wall, 20 gauge metal tubing available in steel, 316 stainless steel and titanium. • 1” diameter tubing and 1” MNPT connection fittings standard. • 4.6 square foot to 89.9 square foot of exchange area • Single point connections reduce the potential for leaks and simplify installation

Features • Wide variety of materials available for use in heating or cooling applications for alkaline or acid solutions and rinse tanks. Check solution guide or consult with • your chemical supplier for proper sheath material. • Heavy wall, 20 gauge metal tubing available in steel, 316 stainless steel and titanium. • 1” diameter tubing and 1” MNPT connection fittings standard. • 4.6 square foot to 89.9 square foot of exchange area • Single point connections reduce the potential for leaks and simplify installation -

Features • Wide variety of materials available for use in heating or cooling applications for alkaline or acid solutionsand rinse tanks. Check solution guide or consult with your chemical supplier for proper sheath material • Heavy wall, 18 gauge metal tubing available in steel, 316 stainless steel and titanium • 1” diameter tubing and 1” MNPT connection fittings standard • Single point connections reduce the potential for leaks and simplify installation • Tubing sizes: ⅜ inch diameter through 1¼ inch diameter • Helical sizes: From 3¼ inch to 10 ft. diameter available based on tube diameter and wall thickness • Wall thickness: .035 through .065 inches

Features • Wide variety of materials available for use in heating or cooling applications for alkaline or acid solutionsand rinse tanks. Check solution guide or consult with your chemical supplier for proper sheath material • Heavy wall, 18 gauge metal tubing available in steel, 316 stainless steel and titanium • 1” diameter tubing and 1” MNPT connection fittings standard • Single point connections reduce the potential for leaks and simplify installation • Tubing sizes: ⅜ inch diameter through 1¼ inch diameter • Helical sizes: From 3¼ inch to 10 ft. diameter available based on tube diameter and wall thickness • Wall thickness: .035 through .065 inches -

Features • ½-inch (13mm) PFA tubing, .030” (.76mm) thick • All welded construction (shell) • 4½-inch (114mm) diameter polypropylene or PVDF shell • Internally baffled for enhanced heat exchanger performance • “U” factor (depending on flow rate): 25-50 BTU/(hr. x ft² x °F) = 142-284 J/(s x m² x °C) • Shell-side drain connection

Features • ½-inch (13mm) PFA tubing, .030” (.76mm) thick • All welded construction (shell) • 4½-inch (114mm) diameter polypropylene or PVDF shell • Internally baffled for enhanced heat exchanger performance • “U” factor (depending on flow rate): 25-50 BTU/(hr. x ft² x °F) = 142-284 J/(s x m² x °C) • Shell-side drain connection -

Features

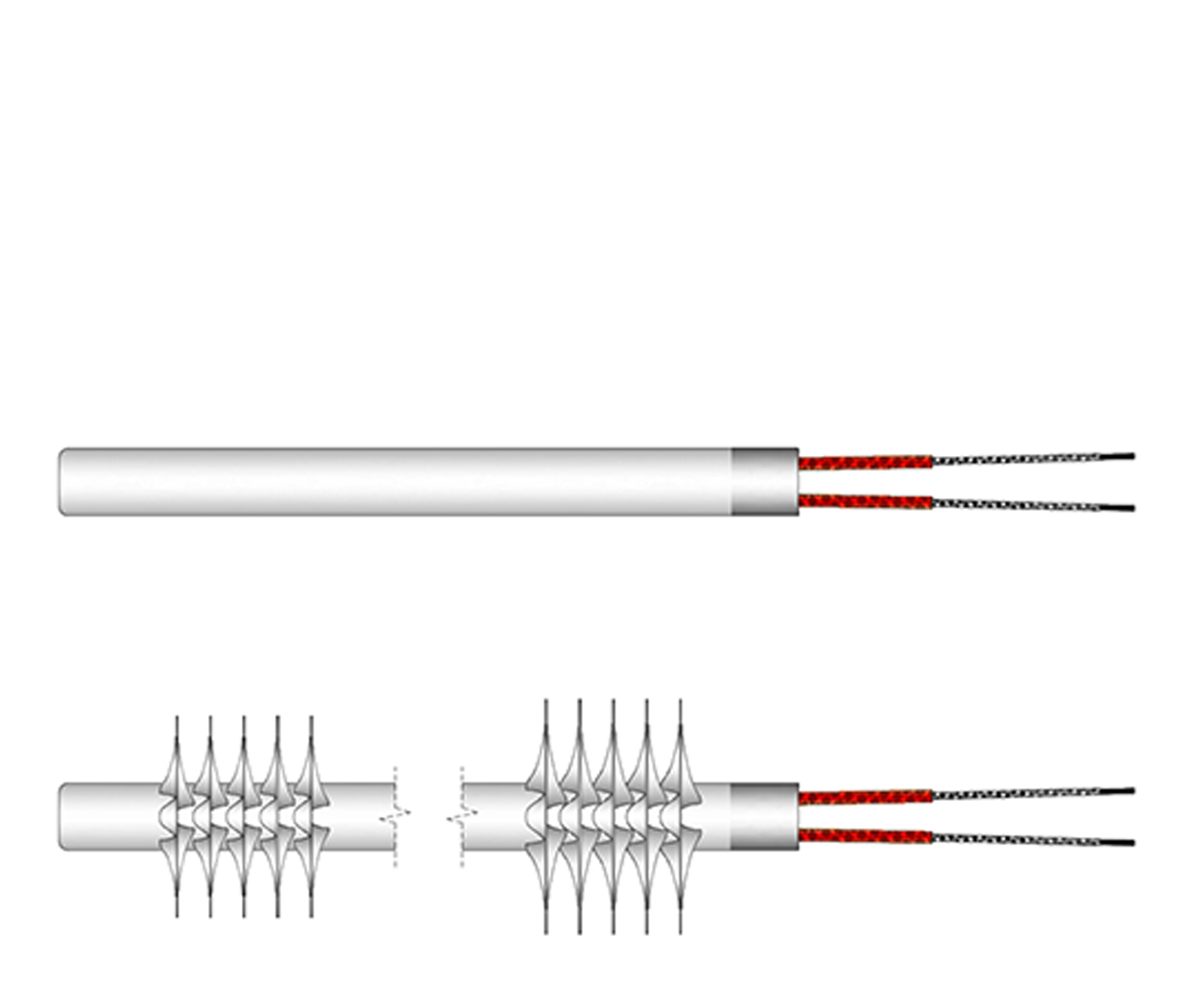

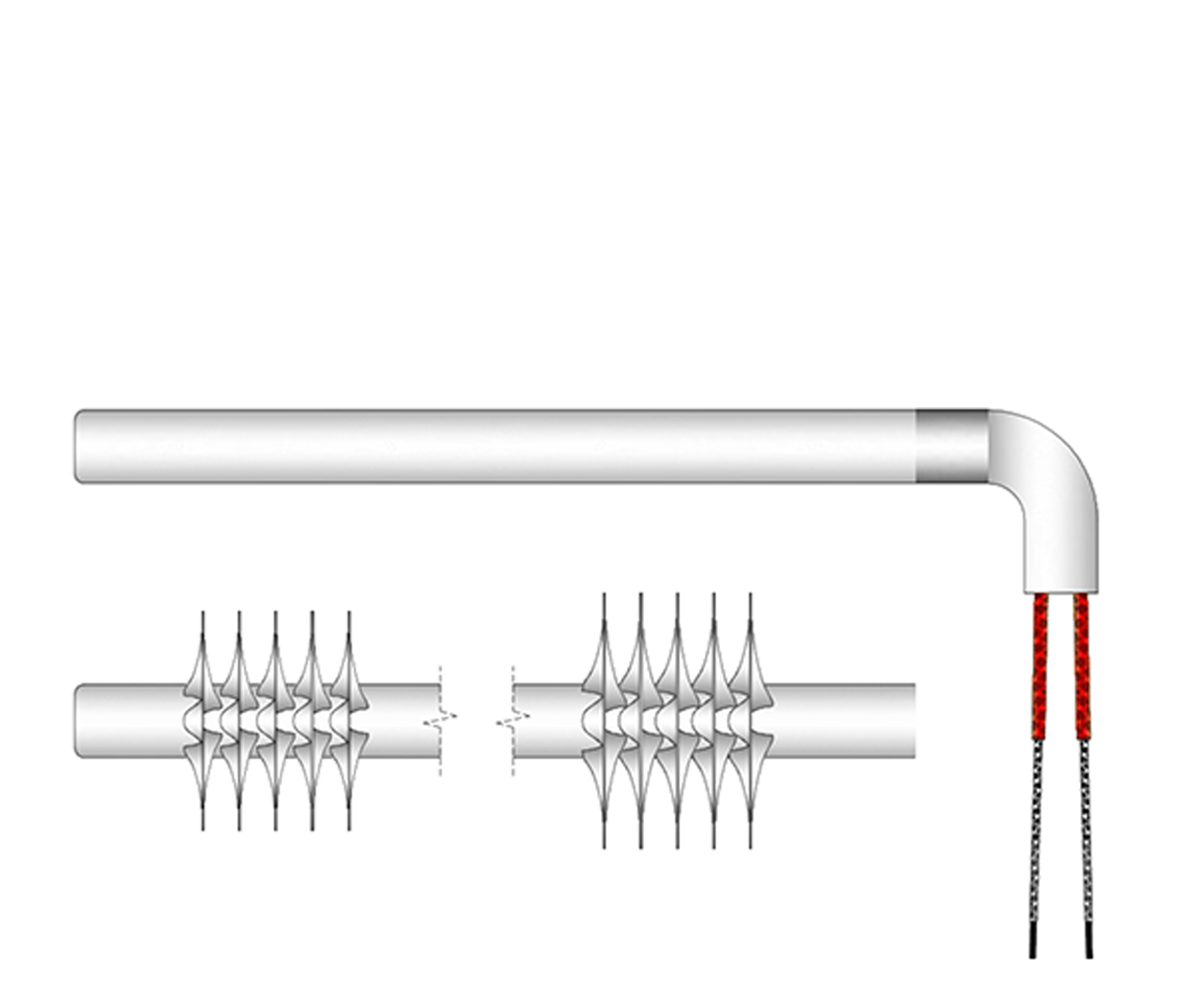

Features- Highly adaptable to most applications where electrical heating is required. They can be used in their straight form or bent into various shapes.

- Used in free air, clamped to a surface, placed inside a groove, or cast into metal.

- Use 80% Nickel 20 % Chromium high-grade coiled resistance wire as a heating core.

-

Features

Features- Highly adaptable to most applications where electrical heating is required. They can be used in their straight form or bent into various shapes.

- Used in free air, clamped to a surface, placed inside a groove, or cast into metal.

- Use 80% Nickel 20 % Chromium high-grade coiled resistance wire as a heating core.

-

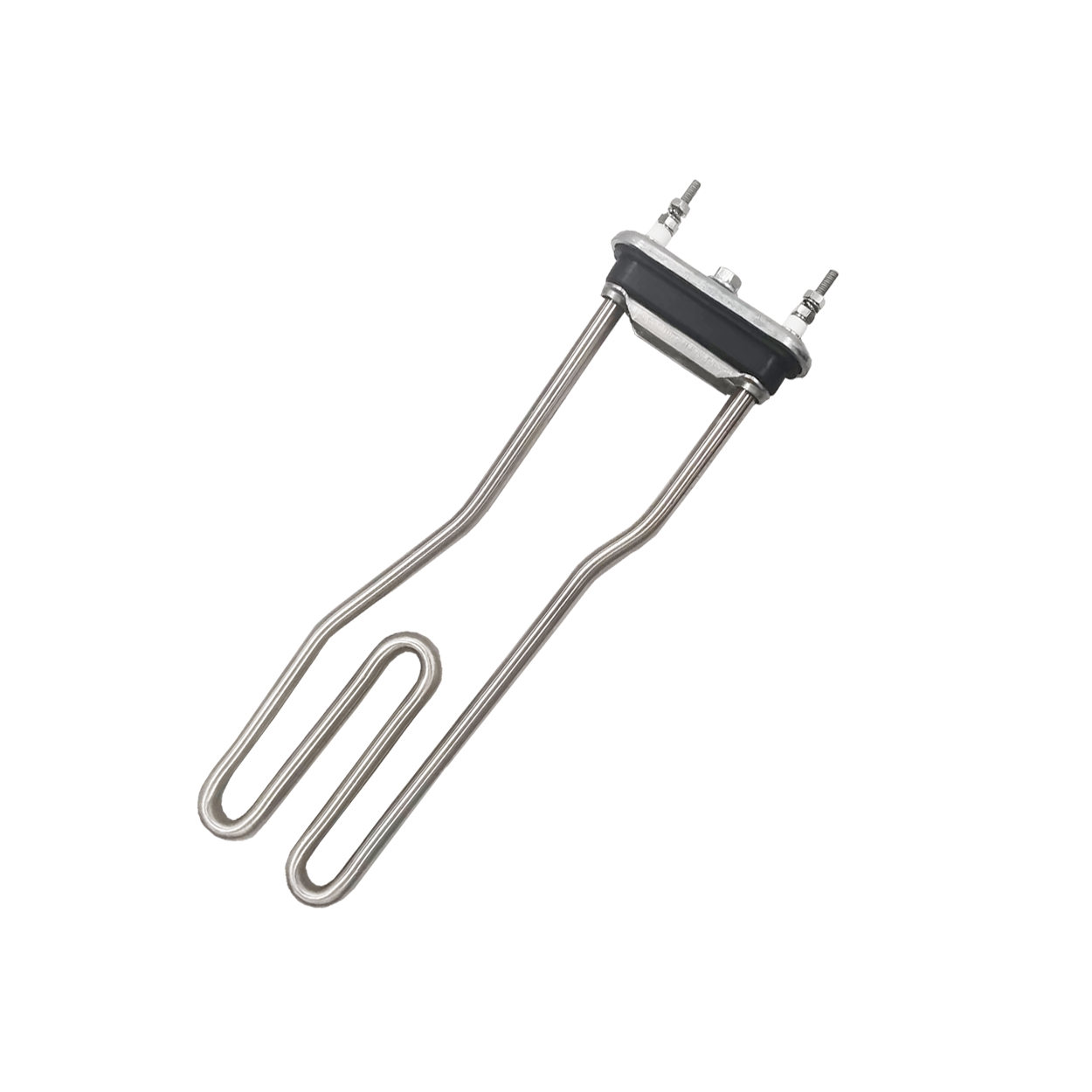

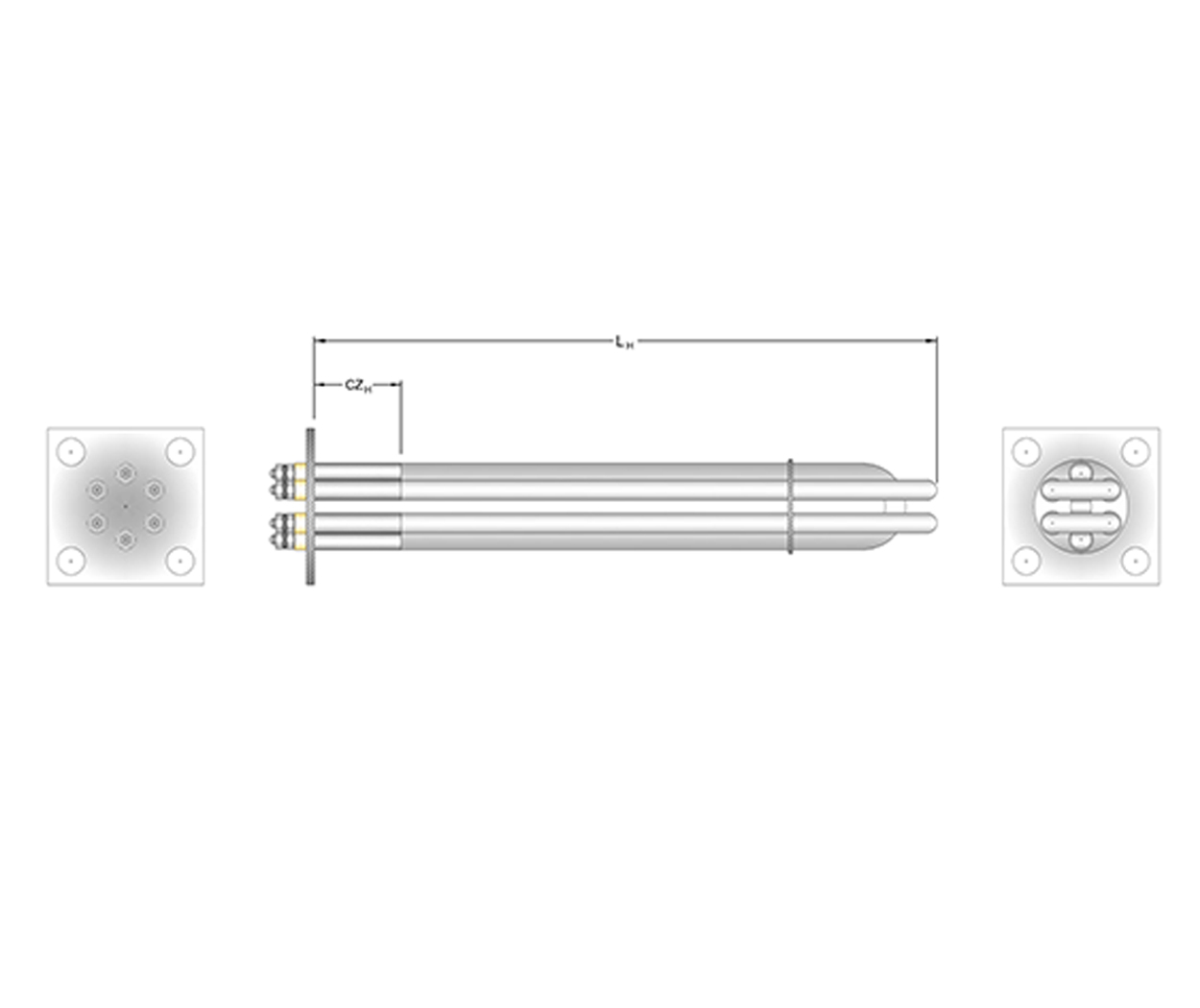

Application

Application- Screw Plug Immersion Heaters are used for heating liquids and gases in a variety of processes.

- These heaters are ideal for process water heating and freeze protection.

- These heaters are ideal for process water heating and freeze protection. All types of oils and heat transfer solutions can also be heated using these compact, easily controlled units.

- The direct immersion method is energy efficient and well suited for many applications. "Hot Water Storage Tanks" "Warming Equipment" "Preheating all Grades of Oil" "Food Processing Equipment" "Cleaning and Rinsing Tanks" "Heat Transfer Systems" "Process Air Equipment" "Boiler Equipment" "Freeze Protection of Any Fluid"

- The heated media, viscosity, specific heat, density and corrosive properties.

- Contaminants or pH present in the media.

- The corrosion resistant properties of heater sheath material.

- Watt density of the heating element the heat output per square inch.

- Screw plug material.

-

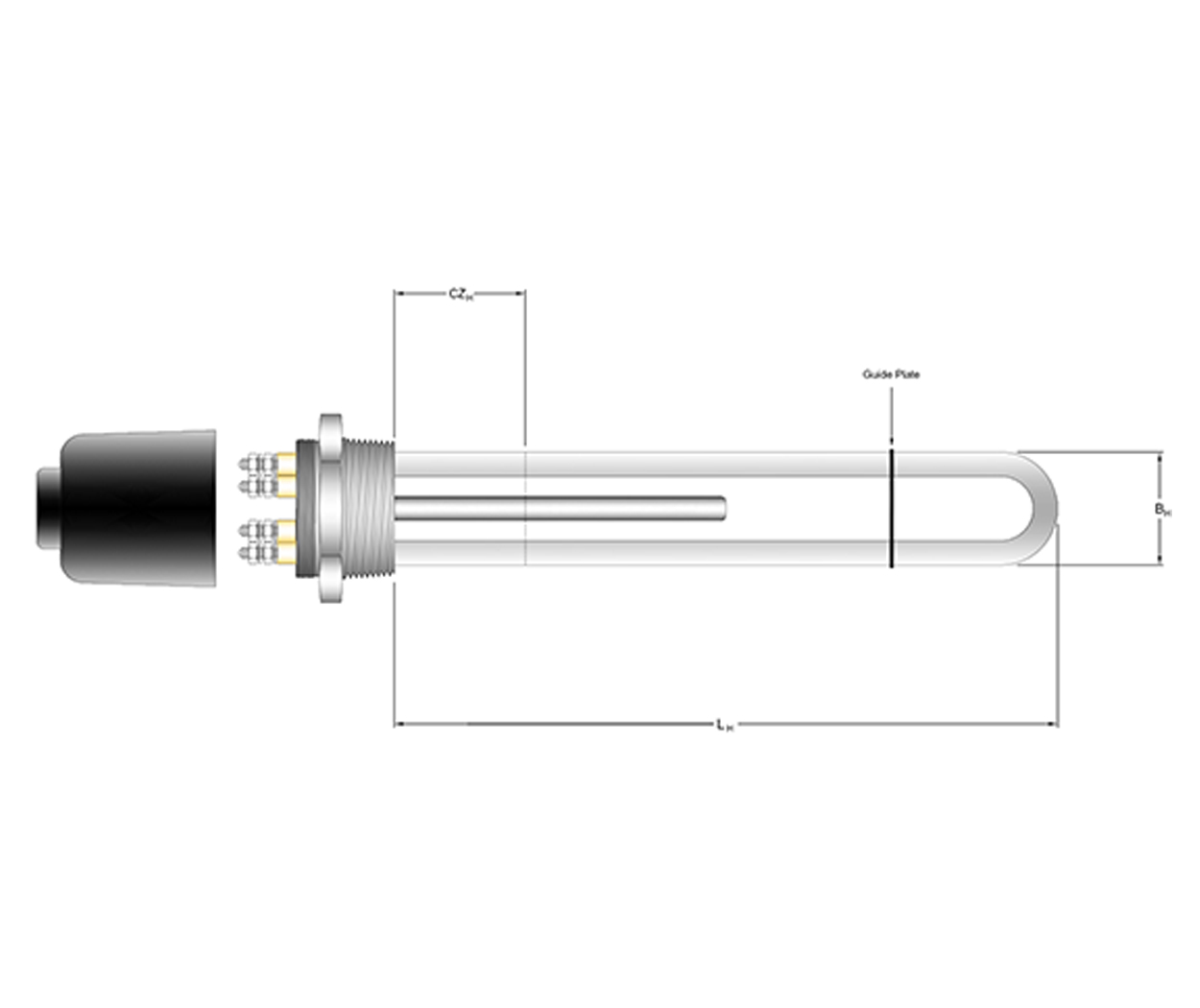

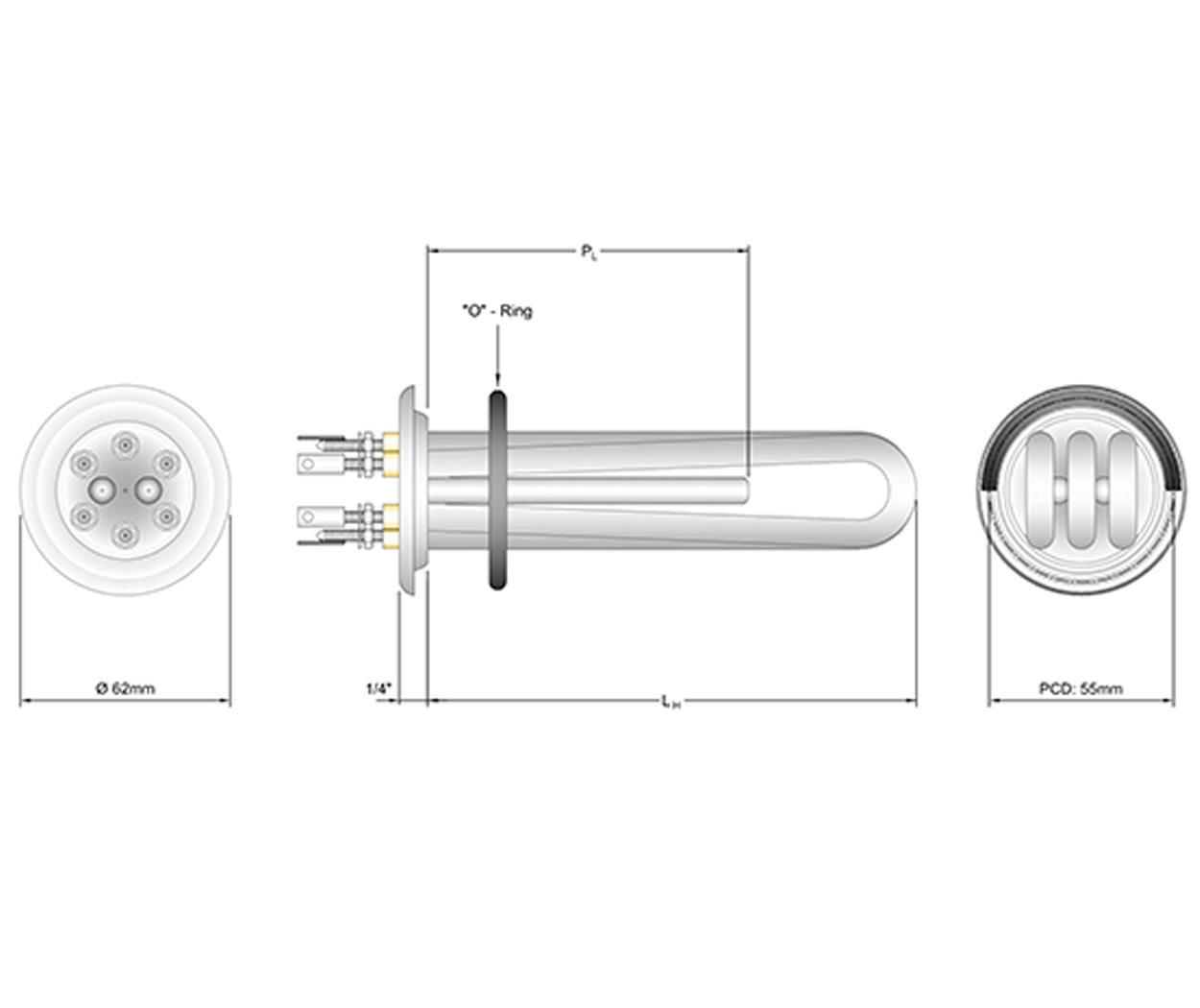

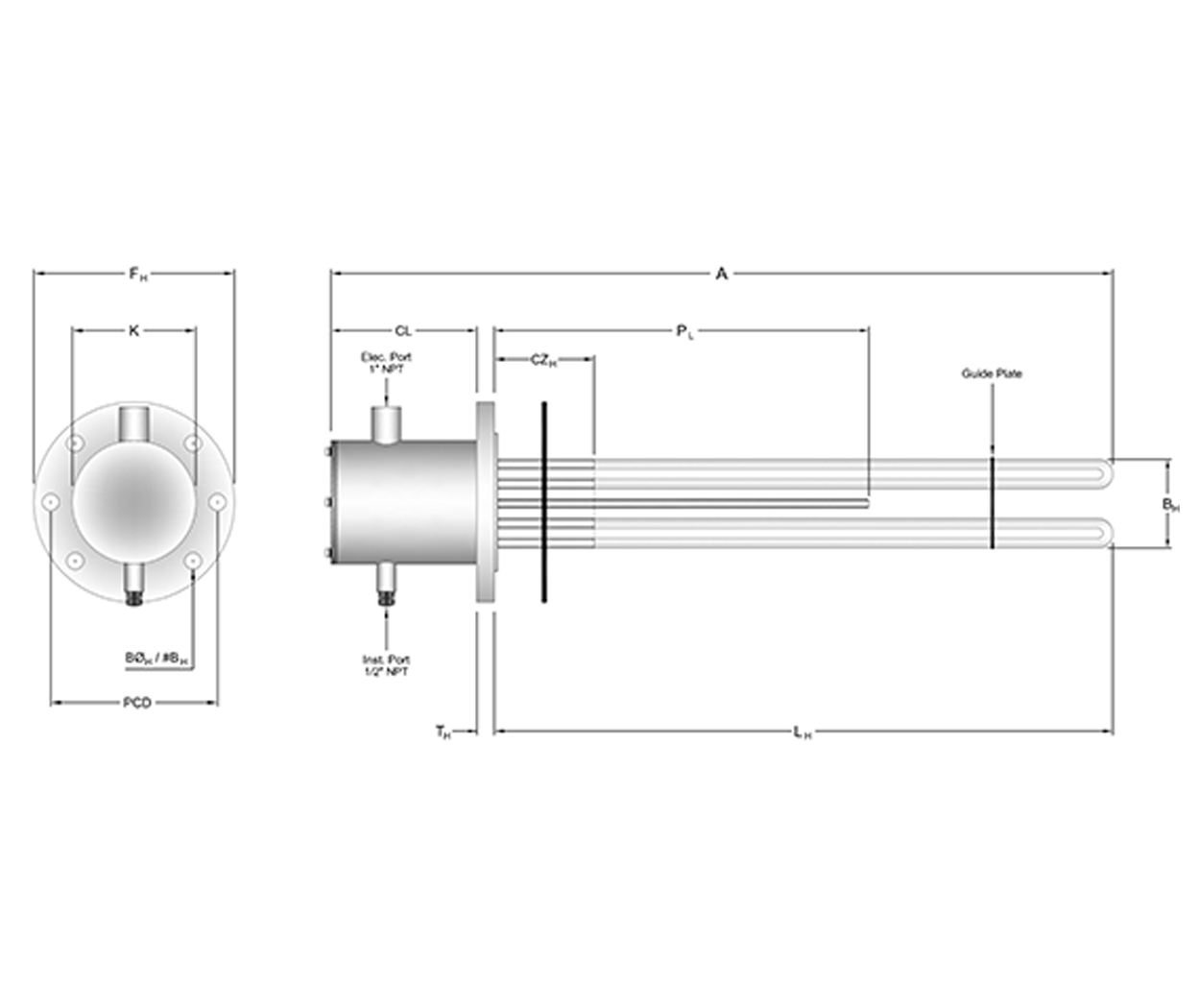

Application

Application- Flanged immersion heaters are one of the most widely used methods for heating gases and liquids (such as water, oil, heat transfer fluid and corrosive solutions ).

- Designed for use in tanks and pressurized vessels, they are easy to install and maintain to provide heat for many processes.

- The direct immersion method is energy efficient and easily monitored and controlled. "Hot Water Storage Tanks" "Warming Equipment" "Preheating all Grades of Oil" "Food Processing Equipment" "Cleaning and Rinsing Tanks" "Heat Transfer Systems" "Process Air Equipment" "Boiler Equipment" "Freeze Protection of Any Fluid"

- The heated media, viscosity, specific heat, density and corrosive properties.

- Contaminants are present in the medium.

- The heater sheath material corrosion resistant properties.

- Watt density of the heating element the heat output per square inch.

- Maximum sheath temperature this is the recommended maximum sheath temperature of the element material. It is not the operating temperature of the heated medium

-

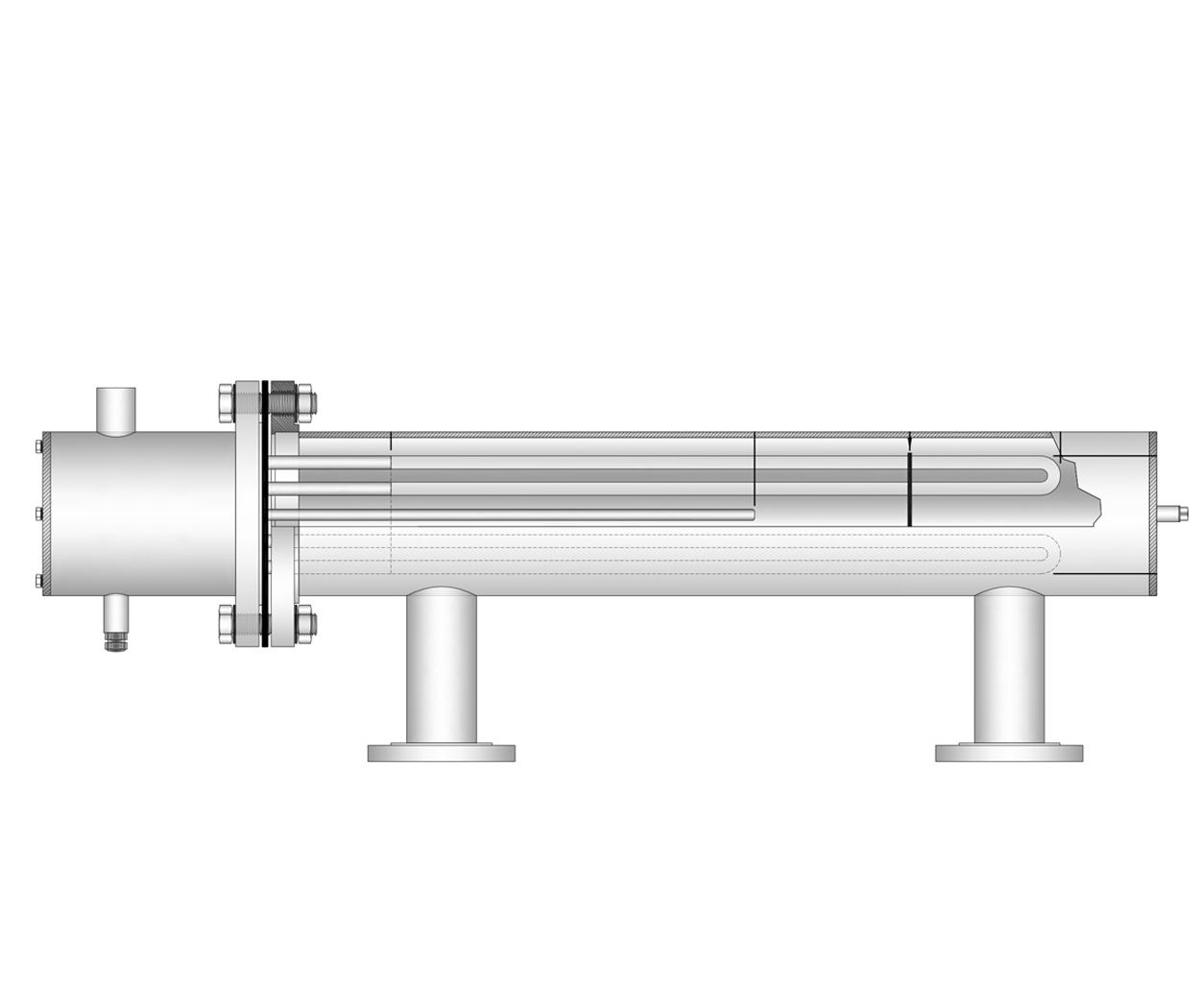

Application

Application- Flanged immersion heaters are one of the most widely used methods for heating gases and liquids (such as water, oil, heat transfer fluid and corrosive solutions ).

- Designed for use in tanks and pressurized vessels, they are easy to install and maintain to provide heat for many processes.

- The direct immersion method is energy efficient and easily monitored and controlled. "Hot Water Storage Tanks" "Warming Equipment" "Preheating all Grades of Oil" "Food Processing Equipment" "Cleaning and Rinsing Tanks" "Heat Transfer Systems" "Process Air Equipment" "Boiler Equipment" "Freeze Protection of Any Fluid"

- The heated media, viscosity, specific heat, density and corrosive properties.

- Contaminants present in the medium.

- The heater sheath material corrosion resistant properties.

- Watt density of the heating element the heat output per square inch.

- Maximum sheath temperature this is the recommended maximum sheath temperature of the element material. It is not the operating temperature of the heated medium

-

Application

Application- Flanged immersion heaters are one of the most widely used methods for heating gases and liquids (such as water, oil, heat transfer fluid and corrosive solutions ).

- Designed for use in tanks and pressurized vessels, they are easy to install and maintain to provide heat for many processes.

- The direct immersion method is energy efficient and easily monitored and controlled. "Hot Water Storage Tanks" "Warming Equipment" "Preheating all Grades of Oil" "Food Processing Equipment" "Cleaning and Rinsing Tanks" "Heat Transfer Systems" "Process Air Equipment" "Boiler Equipment" "Freeze Protection of Any Fluid"

- The heated media, viscosity, specific heat, density and corrosive properties.

- Contaminants present in the medium.

- The heater sheath material corrosion resistant properties.

- Watt density of the heating element the heat output per square inch.

- Maximum sheath temperature this is the recommended maximum sheath temperature of the element material. It is not the operating temperature of the heated medium.

-

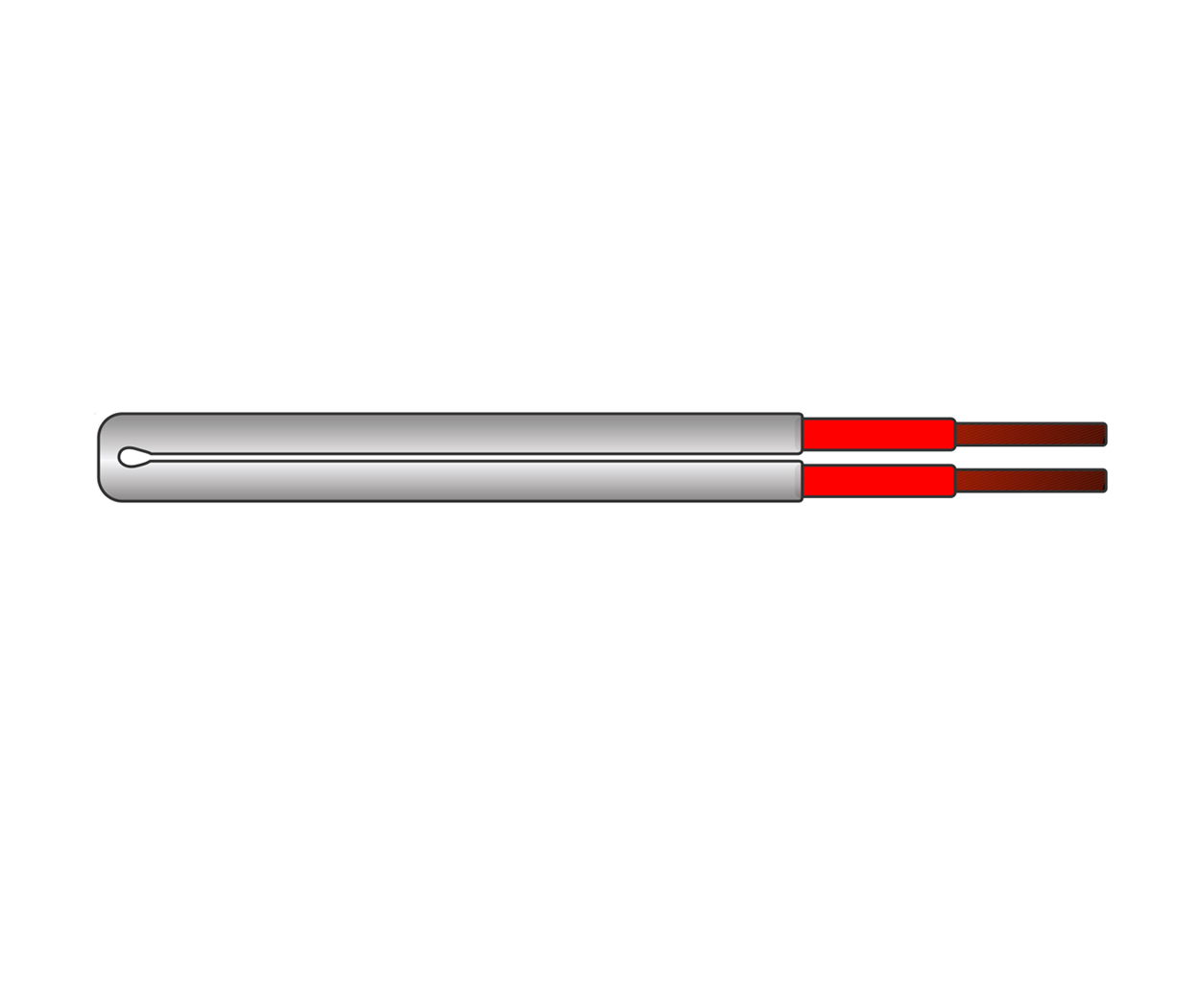

Typical Applications » Water Heating "Washrooms, dishwashing and rinsing, process water heating, jacket kettles, hot water storage tanks, and hydronic heating systems" » Freeze Protection Water cooled engines, standpipe water tanks for fire protection, oil sump heaters" » Heat Transfer Oil Heating "Process kettles, molding dies and platens, mixing and blending mills, closed-loop heat transfer systems for asphalt and heat sensitive materials" » Fuel Oil Heating "Preheating to pumping viscosity, preheating for delivery to burners" » Steam, Air and Gas Heating "Steam super heating, air preheating for process equipment"

Typical Applications » Water Heating "Washrooms, dishwashing and rinsing, process water heating, jacket kettles, hot water storage tanks, and hydronic heating systems" » Freeze Protection Water cooled engines, standpipe water tanks for fire protection, oil sump heaters" » Heat Transfer Oil Heating "Process kettles, molding dies and platens, mixing and blending mills, closed-loop heat transfer systems for asphalt and heat sensitive materials" » Fuel Oil Heating "Preheating to pumping viscosity, preheating for delivery to burners" » Steam, Air and Gas Heating "Steam super heating, air preheating for process equipment" -

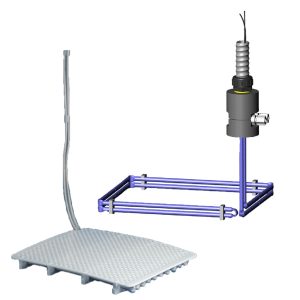

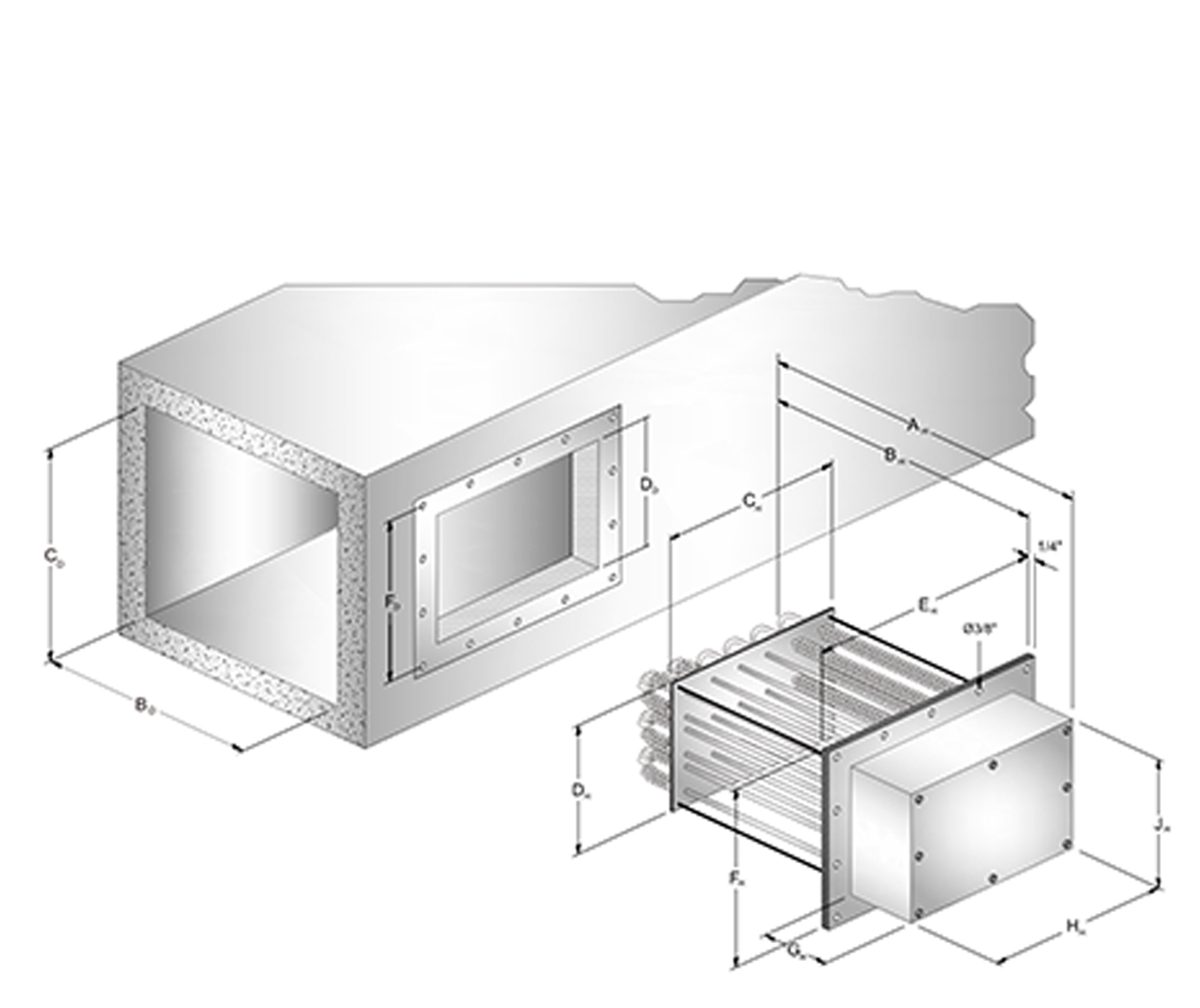

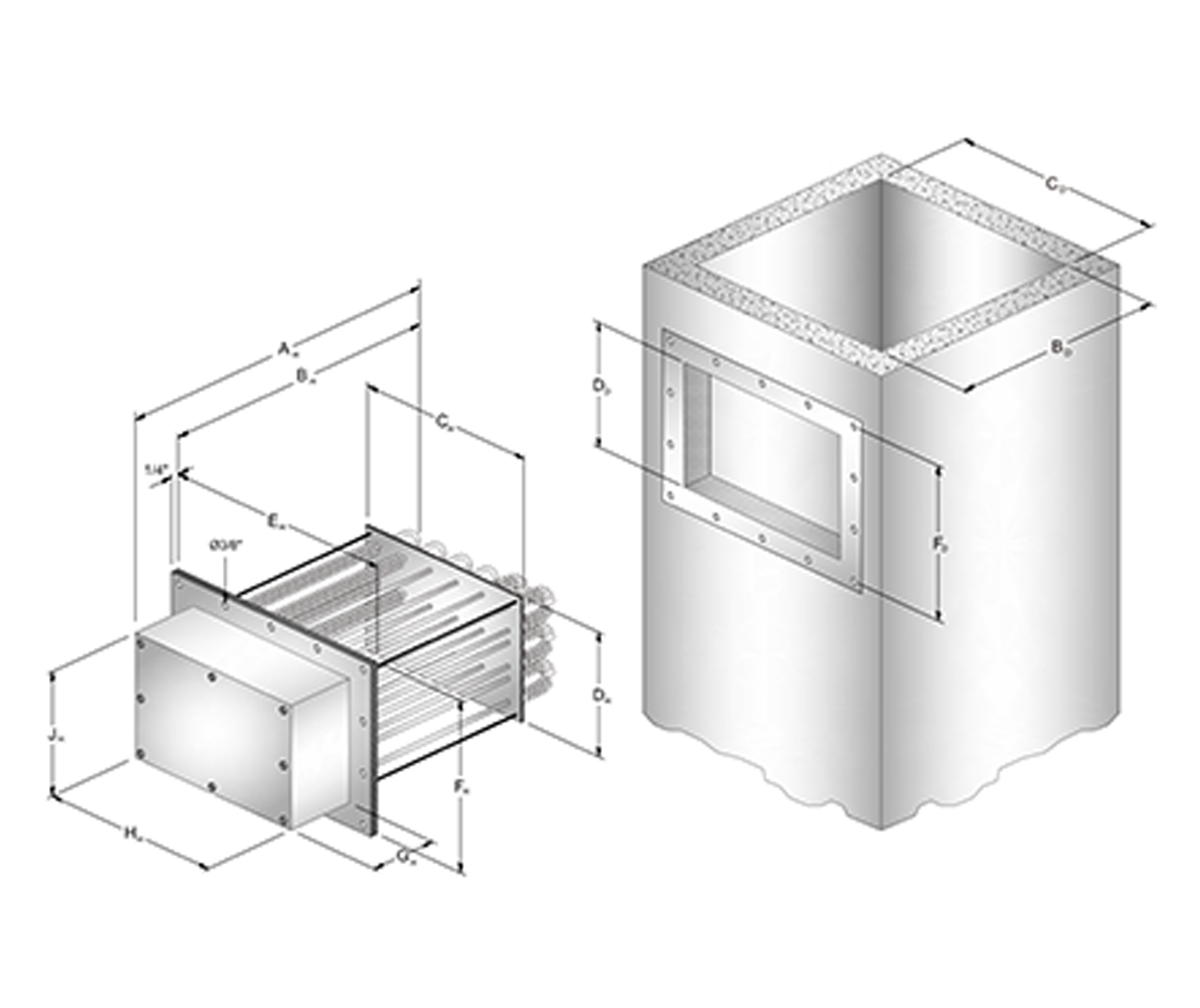

Terminal Air Heater

Terminal Air Heater- Located ahead of the blowing vents in an air-conditioning network. It is relatively low powered (a few kW)

- Circular duct heaters or "drawer type" duct heaters are the most widespread in use.

- "Drawer-type" heaters, which are designed to be installed directly in an opening made in the duct, are built around stored elements.

- They are bent upon request and can be delivered in small series in a week.

- Located upstream from the duct network at the air treatment station level

- It heats the treated air volume in its totality. Its power reaches a few tens of kW.

- Consisting of bare tubular elements or finned tubular elements, these duct heaters generate low transition losses. They are usually built around stored elements, assuring short delivery deadlines, and are installed in a frame made of galvanized steel sheet (stainless on request) sized to the dimensions of the blowing duct.

-

Terminal Air Heater

Terminal Air Heater- Located ahead of the blowing vents in an air-conditioning network. It is relatively low powered (a few kW)

- Circular duct heaters or "drawer type" duct heaters are the most widespread in use.

- "Drawer-type" heaters, which are designed to be installed directly in an opening made in the duct, are built around stored elements.

- They are bent upon request and can be delivered in small series in a week.

- Located upstream from the duct network at the air treatment station level

- It heats the treated air volume in its totality. Its power reaches a few tens of kW.

- Consisting of bare tubular elements or finned tubular elements, these duct heaters generate low transition losses. They are usually built around stored elements, assuring short delivery deadlines, and are installed in a frame made of galvanized steel sheet (stainless on request) sized to dimensions of blowing duct