-

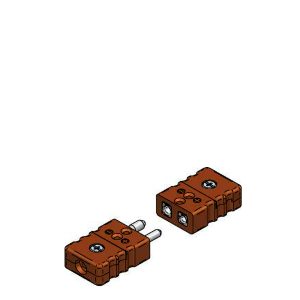

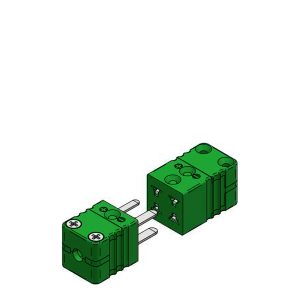

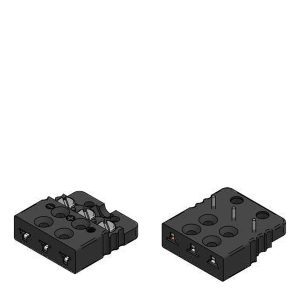

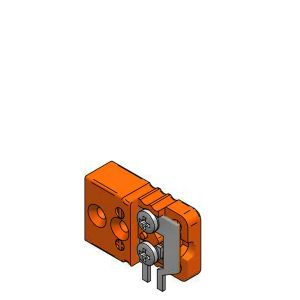

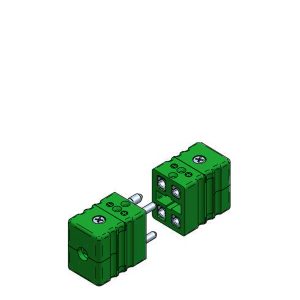

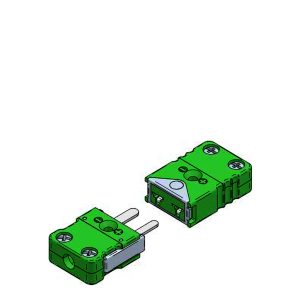

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins • Central cover screw design for quick wiring • Molded barriers prevent short circuit • Captive cover screw for easy assembly • Connects with standard horizontal and vertical panels

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins • Central cover screw design for quick wiring • Molded barriers prevent short circuit • Captive cover screw for easy assembly • Connects with standard horizontal and vertical panels -

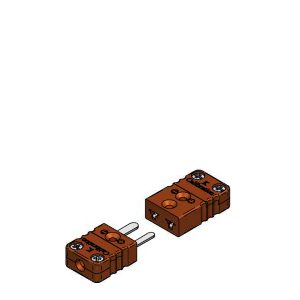

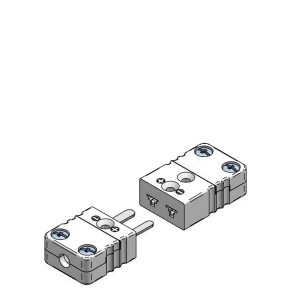

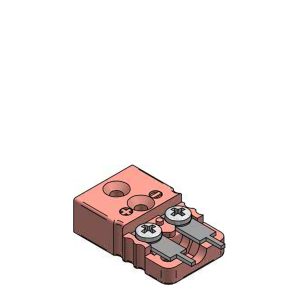

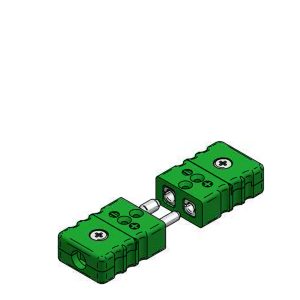

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins • Central cover screw design for quick wiring • Molded barriers prevent short circuit • Captive cover screw for easy assembly • Connects with standard horizontal and vertical panels

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins • Central cover screw design for quick wiring • Molded barriers prevent short circuit • Captive cover screw for easy assembly • Connects with standard horizontal and vertical panels -

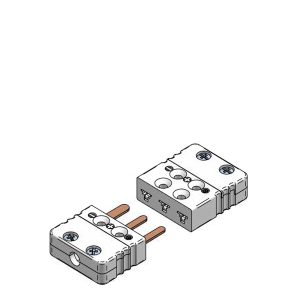

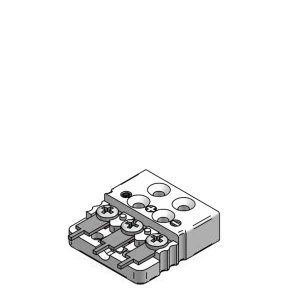

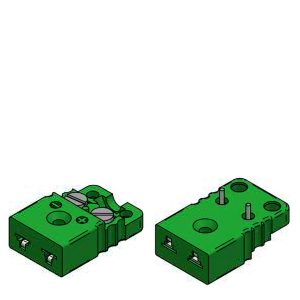

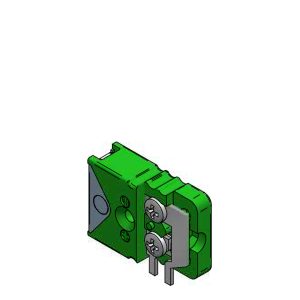

Features • Glass filled high quality thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins • Central cover screw design for quick wiring • Molded barriers prevent short circuit • Captive cover screw for easy assembly • Easy wire connection through sandwich construction • Stainless Steel screws with Phillips head

Features • Glass filled high quality thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins • Central cover screw design for quick wiring • Molded barriers prevent short circuit • Captive cover screw for easy assembly • Easy wire connection through sandwich construction • Stainless Steel screws with Phillips head -

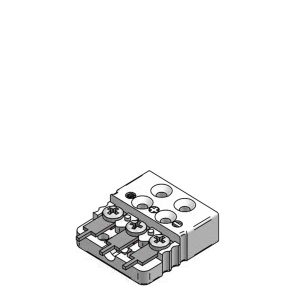

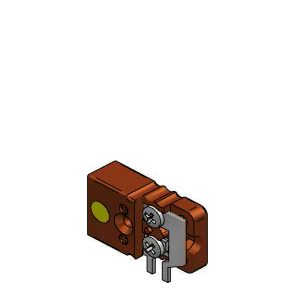

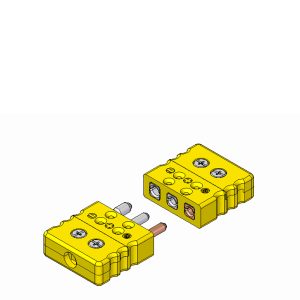

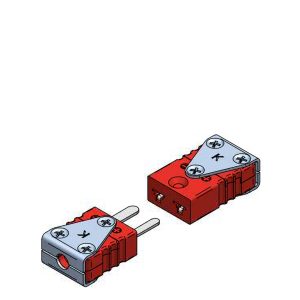

Features • Body of ultra high temp thermoset compound with original thermocouple material pins and springloaded inserts. • Polarized pins ensure proper connection. • Easy wire connection through sandwich construction. • Molded barriers prevent short circuit. • Rugged one body design. • Stainless steel bracket and screws for usage in robust environment

Features • Body of ultra high temp thermoset compound with original thermocouple material pins and springloaded inserts. • Polarized pins ensure proper connection. • Easy wire connection through sandwich construction. • Molded barriers prevent short circuit. • Rugged one body design. • Stainless steel bracket and screws for usage in robust environment -

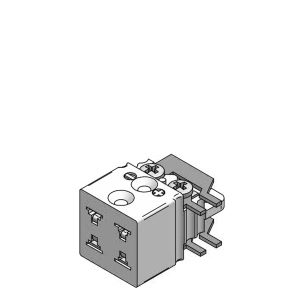

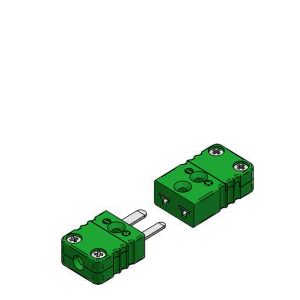

Features • Glass filled high quality thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins ensure proper connection • Easy wire connection through sandwich construction • Molded barriers prevent short circuit • Rugged one body design • Stainless Steel screws with Phillips head

Features • Glass filled high quality thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins ensure proper connection • Easy wire connection through sandwich construction • Molded barriers prevent short circuit • Rugged one body design • Stainless Steel screws with Phillips head -

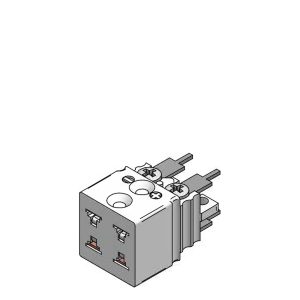

Features • Glass filled high quality thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins ensure proper connection • Easy wire connection through sandwich construction • Molded barriers prevent short circuit • Rugged one body design • Stainless Steel screws with Phillips head • Stainless steel locking clip • Locking Connector Miniature also fits on our part numbers CMP and CMJ

Features • Glass filled high quality thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins ensure proper connection • Easy wire connection through sandwich construction • Molded barriers prevent short circuit • Rugged one body design • Stainless Steel screws with Phillips head • Stainless steel locking clip • Locking Connector Miniature also fits on our part numbers CMP and CMJ -

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts. • Copper pins with silver plating • Rugged one body design. • Stainless steel locking clip • Locking Connector Jack Miniature also accepts Miniature • Connector Plugs without locking feature

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts. • Copper pins with silver plating • Rugged one body design. • Stainless steel locking clip • Locking Connector Jack Miniature also accepts Miniature • Connector Plugs without locking feature -

Features

Features- MultiCon = Meter + Controller + Recorder + HMI + SCADA in one package

- Stable firmware based on Linux

- 13 available input/output blocks

- Colour LCD display 3,5" TFT, with touchscreen

- Recording data with maximum speed 10Hz (ten samples per second)

- 2 or 4 GB internal data memory

- RS-485 (Modbus RTU), USB Host, Ethernet communication

- Wall mounted IP 65 case

-

Features

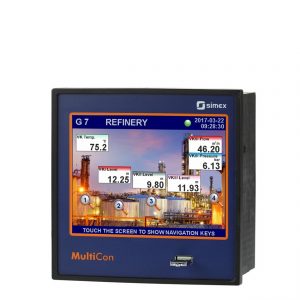

Features- MultiCon = Meter + Controller + Recorder + HMI + SCADA in one package

- stable firmware based on Linux

- 27 available input/output modules

- 60 logical channels

- colour LCD display 3.5" TFT, with touchscreen

- recording data with maximum speed 10Hz (ten samples per second)

- 2 or 4 GB internal data memory

- RS-485 (Modbus RTU), USB Host, Ethernet communication

- panel, compact device in 96 x 96 mm case

-

Features

Features- MultiCon = Meter + Controller + Recorder + HMI + SCADA in one package

- stable firmware based on Linux

- 41 available input/output modules

- 90 logical channels

- colour LCD display 5.7" TFT, with touchscreen

- recording data with maximum speed 10Hz (ten samples per second)

- 2 or 4 GB internal data memory

- RS-485 (Modbus RTU), USB Host, Ethernet communication

- panel, compact device in 144 x 144 mm case