- Wall mount enclosure for DM3000 / DM4500 panel meters

- Impact Resistant ABS Plastic

- Pre Cut – ready to use

-

Features • Integrated 3 sensors in 1 device with LCD display • Measuring temperature, humidity and carbon dioxide • 2 analog outputs and Modbus RS-485 • Optional analog output + RS-485 • Quick easy installation and maintenance due to well designed • Cost-efficient and reliable • Data can be logged and transferred to PC via RS-485 function link free software

Features • Integrated 3 sensors in 1 device with LCD display • Measuring temperature, humidity and carbon dioxide • 2 analog outputs and Modbus RS-485 • Optional analog output + RS-485 • Quick easy installation and maintenance due to well designed • Cost-efficient and reliable • Data can be logged and transferred to PC via RS-485 function link free software -

Features • IP67, Stainless steel SUS304, Pressure resistance 16 bar • 330° rotatable, lightweight, unrestricted installation • Optional on-site real-time display • Process temperature up to 180°C, custom up to 200°C (Optional) • Output:Analog / RS-485 • Wide measurement range, Temp. : -40 ... +180°C, Humidity : 0 ... 100%RH • Measuring parameter:relative humidity, dew point temperature, frost point temperature, wet-bulb temperature, vapor pressure, mixture ratio, absolute humidity and specific enthalpy.

Features • IP67, Stainless steel SUS304, Pressure resistance 16 bar • 330° rotatable, lightweight, unrestricted installation • Optional on-site real-time display • Process temperature up to 180°C, custom up to 200°C (Optional) • Output:Analog / RS-485 • Wide measurement range, Temp. : -40 ... +180°C, Humidity : 0 ... 100%RH • Measuring parameter:relative humidity, dew point temperature, frost point temperature, wet-bulb temperature, vapor pressure, mixture ratio, absolute humidity and specific enthalpy. -

Features • Industrial sensor comes with high accuracy and long-term stability • Capable of temperature compensation and linear calibration • 2 analog output or Modbus RS-485 • Optional analog output + RS-485 • Probe:PC • Power supply:DC 8 ... 35 V and AC 12 ... 30 VRS-485 and Modbus RTU • Free programmable software - Physical quantities / Output / Data logger / Charts / Calibration

Features • Industrial sensor comes with high accuracy and long-term stability • Capable of temperature compensation and linear calibration • 2 analog output or Modbus RS-485 • Optional analog output + RS-485 • Probe:PC • Power supply:DC 8 ... 35 V and AC 12 ... 30 VRS-485 and Modbus RTU • Free programmable software - Physical quantities / Output / Data logger / Charts / Calibration -

Features • IP65 , rugged aluminum case, fit in variety harsh environment • Capable of temperature compensation. Linear adjustment temperature & humidity by computer, analog output or option RS-485 • Measure high accuracy Temp. & humidity, reaction quickly, the sensor can work well after temporary condensation, long term stable in high humidity environment • Process Temp. : up to 200°C, S.S. probe proof pressure : 10 bar, metal connector : installation repeatedly • Switch multifunction physical quantities:[%RH]、[°C]、[mbar]、[g/kg]、[g/m3]、[kj/kg] • Calibration physical quantities, measuring range, analog output, station, etc • Free calibration software : data logger / record 65535 datas / charts

Features • IP65 , rugged aluminum case, fit in variety harsh environment • Capable of temperature compensation. Linear adjustment temperature & humidity by computer, analog output or option RS-485 • Measure high accuracy Temp. & humidity, reaction quickly, the sensor can work well after temporary condensation, long term stable in high humidity environment • Process Temp. : up to 200°C, S.S. probe proof pressure : 10 bar, metal connector : installation repeatedly • Switch multifunction physical quantities:[%RH]、[°C]、[mbar]、[g/kg]、[g/m3]、[kj/kg] • Calibration physical quantities, measuring range, analog output, station, etc • Free calibration software : data logger / record 65535 datas / charts -

Features • Dew point calibration, highly accuracy, 4 ... 20 mA and RS-485 output • Reduce insensitivity temperature zone, quickly response • Hysteresis compensation, resistance to moisture, extreme high and low humidity impact • EMC anti-interference, anti-condensation, low-temperature influence, long-term stability • Three thread (1/2″PT, 1/2″G, and 5/8″UNF) mode can be selected

Features • Dew point calibration, highly accuracy, 4 ... 20 mA and RS-485 output • Reduce insensitivity temperature zone, quickly response • Hysteresis compensation, resistance to moisture, extreme high and low humidity impact • EMC anti-interference, anti-condensation, low-temperature influence, long-term stability • Three thread (1/2″PT, 1/2″G, and 5/8″UNF) mode can be selected -

Features

Features- MultiCon = Meter + Controller + Recorder + HMI + SCADA in one package

- Stable firmware based on Linux

- 13 available input/output blocks

- Colour LCD display 3,5" TFT, with touchscreen

- Recording data with maximum speed 10Hz (ten samples per second)

- 2 or 4 GB internal data memory

- RS-485 (Modbus RTU), USB Host, Ethernet communication

- Wall mounted IP 65 case

-

Features

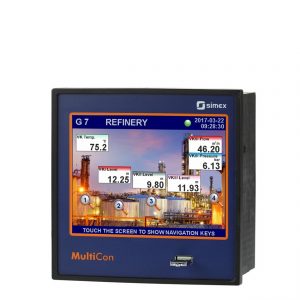

Features- MultiCon = Meter + Controller + Recorder + HMI + SCADA in one package

- stable firmware based on Linux

- 27 available input/output modules

- 60 logical channels

- colour LCD display 3.5" TFT, with touchscreen

- recording data with maximum speed 10Hz (ten samples per second)

- 2 or 4 GB internal data memory

- RS-485 (Modbus RTU), USB Host, Ethernet communication

- panel, compact device in 96 x 96 mm case

-

Features

Features- MultiCon = Meter + Controller + Recorder + HMI + SCADA in one package

- stable firmware based on Linux

- 41 available input/output modules

- 90 logical channels

- colour LCD display 5.7" TFT, with touchscreen

- recording data with maximum speed 10Hz (ten samples per second)

- 2 or 4 GB internal data memory

- RS-485 (Modbus RTU), USB Host, Ethernet communication

- panel, compact device in 144 x 144 mm case

-

Features • Operator interface with color touch screen display, 3.5 “ • Up to 8 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 200 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Management of active and historic alarms • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection

Features • Operator interface with color touch screen display, 3.5 “ • Up to 8 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 200 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Management of active and historic alarms • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection -

Features • Operator interface with color touch screen display, 7” • Up to 16 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 250 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection

Features • Operator interface with color touch screen display, 7” • Up to 16 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 250 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection -

Features • Multi-input and multi-range performance • Small instrument depths (62mm - 65mm) save space, thus securing a larger installation area. • SV setting: 3 points • PID Value: 3 types • 2-output heating and cooling control available (optional) • Total 32 steps Program available (optional) (1-4 pattern, 32-8 step) • RS-485 Interface available (optional) (Master/slave function, Modbus/Shimaden Protocol) • Heater break/heater loop alarm (optional) • A wide selection of additional functions (optional) is available to suit various needs. • Possible to switch off SV/PV value by key operation • Parameter mask (non-display) / lock (key lock) function

Features • Multi-input and multi-range performance • Small instrument depths (62mm - 65mm) save space, thus securing a larger installation area. • SV setting: 3 points • PID Value: 3 types • 2-output heating and cooling control available (optional) • Total 32 steps Program available (optional) (1-4 pattern, 32-8 step) • RS-485 Interface available (optional) (Master/slave function, Modbus/Shimaden Protocol) • Heater break/heater loop alarm (optional) • A wide selection of additional functions (optional) is available to suit various needs. • Possible to switch off SV/PV value by key operation • Parameter mask (non-display) / lock (key lock) function -

Features • Multi-input and multi-range performance • Small instrument depths (62mm - 65mm) save space, thus securing a larger installation area. • SV setting: 3 points • PID Value: 3 types • 2-output heating and cooling control available (optional) • Total 32 steps Program available (optional) (1-4 pattern, 32-8 step) • RS-485 Interface available (optional) (Master/slave function, Modbus/Shimaden Protocol) • Heater break/heater loop alarm (optional) • A wide selection of additional functions (optional) is available to suit various needs. • Possible to switch off SV/PV value by key operation • Parameter mask (non-display) / lock (key lock) function

Features • Multi-input and multi-range performance • Small instrument depths (62mm - 65mm) save space, thus securing a larger installation area. • SV setting: 3 points • PID Value: 3 types • 2-output heating and cooling control available (optional) • Total 32 steps Program available (optional) (1-4 pattern, 32-8 step) • RS-485 Interface available (optional) (Master/slave function, Modbus/Shimaden Protocol) • Heater break/heater loop alarm (optional) • A wide selection of additional functions (optional) is available to suit various needs. • Possible to switch off SV/PV value by key operation • Parameter mask (non-display) / lock (key lock) function -

Features • Universal input configurable from faceplate • Accuracy better than 0.2% f.s. under nominal conditions • Control output: relay, logic, Triac , continuous, digital insulated • Hot/cold function with selection of cooling fluid • 3 alarms with completely configurable function • Analog retransmission output • Isolated digital input with configurable function • Auxiliary input for CT (TA) (50mAac) • Heater break or probe short-circuit alarm • Self-tuning, Auto-tuning, Soft-start, bumpless Man/Auto function • Double set, set ramp, timed output function • Optically isolated RS485 serial line. Protocol: GEFRAN CENCAL or MODBUS RTU • Self-diagnosis • Rapid configuration from PC with Winstrum packet

Features • Universal input configurable from faceplate • Accuracy better than 0.2% f.s. under nominal conditions • Control output: relay, logic, Triac , continuous, digital insulated • Hot/cold function with selection of cooling fluid • 3 alarms with completely configurable function • Analog retransmission output • Isolated digital input with configurable function • Auxiliary input for CT (TA) (50mAac) • Heater break or probe short-circuit alarm • Self-tuning, Auto-tuning, Soft-start, bumpless Man/Auto function • Double set, set ramp, timed output function • Optically isolated RS485 serial line. Protocol: GEFRAN CENCAL or MODBUS RTU • Self-diagnosis • Rapid configuration from PC with Winstrum packet -

Features • Universal input configurable from faceplate • Accuracy better than 0.2% f.s. under nominal conditions • Control output: relay, logic, Triac , continuous, digital insulated • Hot/cold function with selection of cooling fluid • 3 alarms with completely configurable function • Analog retransmission output • Isolated digital input with configurable function • Auxiliary input for CT (TA) (50mAac) • Heater break or probe short-circuit alarm • Self-tuning, Auto-tuning, Soft-start, bumpless Man/Auto function • Double set, set ramp, timed output function • Optically isolated RS485 serial line.Protocol: GEFRAN CENCAL or MODBUS RTU • Self-diagnosis • Rapid configuration from PC with Winstrum packet

Features • Universal input configurable from faceplate • Accuracy better than 0.2% f.s. under nominal conditions • Control output: relay, logic, Triac , continuous, digital insulated • Hot/cold function with selection of cooling fluid • 3 alarms with completely configurable function • Analog retransmission output • Isolated digital input with configurable function • Auxiliary input for CT (TA) (50mAac) • Heater break or probe short-circuit alarm • Self-tuning, Auto-tuning, Soft-start, bumpless Man/Auto function • Double set, set ramp, timed output function • Optically isolated RS485 serial line.Protocol: GEFRAN CENCAL or MODBUS RTU • Self-diagnosis • Rapid configuration from PC with Winstrum packet -

Features • Universal input configurable from faceplate • Accuracy better than 0.2% f.s. under nominal conditions • Control output: relay, logic, Triac or continuous • Hot/cold function with selection of cooling fluid • 3 alarms with completely configurable function • Analog retransmission output • Up to 2 isolated digital inputs with configurable function • Isolated digital input with configurable function • Auxiliary input for CT (TA) (50mAac) • Heater break or probe short-circuit alarm • Self-tuning, Auto-tuning, Soft-start, bumpless Man/Auto function • Double set, set ramp, timed output function • Optically isolated RS485 serial line. Protocol: GEFRAN MODBUS RTU • Self-diagnosis • Rapid configuration from PC with Winstrum packet

Features • Universal input configurable from faceplate • Accuracy better than 0.2% f.s. under nominal conditions • Control output: relay, logic, Triac or continuous • Hot/cold function with selection of cooling fluid • 3 alarms with completely configurable function • Analog retransmission output • Up to 2 isolated digital inputs with configurable function • Isolated digital input with configurable function • Auxiliary input for CT (TA) (50mAac) • Heater break or probe short-circuit alarm • Self-tuning, Auto-tuning, Soft-start, bumpless Man/Auto function • Double set, set ramp, timed output function • Optically isolated RS485 serial line. Protocol: GEFRAN MODBUS RTU • Self-diagnosis • Rapid configuration from PC with Winstrum packet -

Features • 2-channel controller (Basic type: 1-channel controller) • Independent 2-loop / Internal Cascade / 2-input operation control • High accuracy ± (0.1% FS + 1 digit) • High Sampling Cycle 0.1 sec. • High resolution 1/ 1000 °C display achieved *Only for R.T.D. input (scale: 0.000~30.000 °C) • Auto-Tuning PID / Expert PID / Self-Tuning PID • Multi-Setting of 10 Set Values • Independent Universal-Input • User Friendly Operation (Menu Driven: 4 Lines LCD Display) • Easy Setting & Maintenance via Infrared COM port on the front panel • Interface RS-232C/RS-485 (MODBUS / Shimaden) • The front dust/splash-proof IP66 • Universal Power Supply (100~240V AC ±10%) • Sensor power supply

Features • 2-channel controller (Basic type: 1-channel controller) • Independent 2-loop / Internal Cascade / 2-input operation control • High accuracy ± (0.1% FS + 1 digit) • High Sampling Cycle 0.1 sec. • High resolution 1/ 1000 °C display achieved *Only for R.T.D. input (scale: 0.000~30.000 °C) • Auto-Tuning PID / Expert PID / Self-Tuning PID • Multi-Setting of 10 Set Values • Independent Universal-Input • User Friendly Operation (Menu Driven: 4 Lines LCD Display) • Easy Setting & Maintenance via Infrared COM port on the front panel • Interface RS-232C/RS-485 (MODBUS / Shimaden) • The front dust/splash-proof IP66 • Universal Power Supply (100~240V AC ±10%) • Sensor power supply -

Features • 3-channel controller, 3-channel input, 3-channel setting and simultaneous 3-channel display are possible • Accuracy: ± (0.3% FS + 1 digit) • Follow-up type PV input function • Follow-up type SV setting function • Remote/local and DI input function • Programmable 1 pattern with 9-step function • Included a new processing system, Expert PID, remarkably improved PID control efficiency; overshoot and undershoot are controlled effectively. • Interface RS232C/RS485

Features • 3-channel controller, 3-channel input, 3-channel setting and simultaneous 3-channel display are possible • Accuracy: ± (0.3% FS + 1 digit) • Follow-up type PV input function • Follow-up type SV setting function • Remote/local and DI input function • Programmable 1 pattern with 9-step function • Included a new processing system, Expert PID, remarkably improved PID control efficiency; overshoot and undershoot are controlled effectively. • Interface RS232C/RS485 -

Features • 2-channel controller (Basic type: 1-channel controller) • Independent 2-loop / 2-input operation control • High accuracy ± (0.1% FS + 1 digit) • High Sampling Cycle 0.1 sec. • High resolution 1/ 1000 °C display achieved *Only for R.T.D. input (scale: 0.000~30.000 °C) • Programmable Max. 400 steps (400 steps x 1 pattern to 20 steps x 20 patterns) • Auto-Tuning PID / Expert PID • Max. 10 Zone PID control available • Independent Universal-Input • User Friendly Operation (Menu Driven: 4 Lines LCD Display) • Easy Setting & Maintenance via Infrared COM port on the front panel • Interface RS-232C/RS-485 (MODBUS / Shimaden) • The front dust/splash-proof IP66 • Universal Power Supply (100~240V AC ±10%) • Sensor power supply

Features • 2-channel controller (Basic type: 1-channel controller) • Independent 2-loop / 2-input operation control • High accuracy ± (0.1% FS + 1 digit) • High Sampling Cycle 0.1 sec. • High resolution 1/ 1000 °C display achieved *Only for R.T.D. input (scale: 0.000~30.000 °C) • Programmable Max. 400 steps (400 steps x 1 pattern to 20 steps x 20 patterns) • Auto-Tuning PID / Expert PID • Max. 10 Zone PID control available • Independent Universal-Input • User Friendly Operation (Menu Driven: 4 Lines LCD Display) • Easy Setting & Maintenance via Infrared COM port on the front panel • Interface RS-232C/RS-485 (MODBUS / Shimaden) • The front dust/splash-proof IP66 • Universal Power Supply (100~240V AC ±10%) • Sensor power supply -

Features • Operator interface with large LCD Display, customizable, with choice of colors • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 16 function block applications • Timer, set point and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • Universal input configurable for thermocouples, resistance thermometers, linear inputs • Remote set point input • Relay, logic, isolated analog outputs • Up to two CT inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU • Removable faceplate for immediate replacement • Sampling time 60ms

Features • Operator interface with large LCD Display, customizable, with choice of colors • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 16 function block applications • Timer, set point and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • Universal input configurable for thermocouples, resistance thermometers, linear inputs • Remote set point input • Relay, logic, isolated analog outputs • Up to two CT inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU • Removable faceplate for immediate replacement • Sampling time 60ms -

Features • Operator interface with large LCD Display and three configurable bargraphs • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even withe power off • Preventive maintenance with energy counters (kWh) and load switching • 32 function block applications • 8 Math application blocks • Timer, set point and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • 2 Universal inputs configurable for thermocouples, resistance thermometers, linear inputs • 1 linear analog input configurable for auxiliary functions • 2 PID control loops • 2 set point programmers (192 steps in 16 programs, or 12 programs with 16 fixed steps each) • Relay, logic, isolated analog outputs • Up to two TA inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU slave • RS485 serial communication in Modbus RTU master for reading/ writing information to Modbus slave devices • Ethernet Modbus TCP communication in Slave mode • Web server for browser access to web pages residing in the device, for monitoring and setting parameters • Bridge function for creation of Modbus RTU 485 sub-network • Weekly clock\calendar with RTC • Removable faceplate for immediate replacement • Accuracy 0,1%, sampling time 60 ms

Features • Operator interface with large LCD Display and three configurable bargraphs • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even withe power off • Preventive maintenance with energy counters (kWh) and load switching • 32 function block applications • 8 Math application blocks • Timer, set point and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • 2 Universal inputs configurable for thermocouples, resistance thermometers, linear inputs • 1 linear analog input configurable for auxiliary functions • 2 PID control loops • 2 set point programmers (192 steps in 16 programs, or 12 programs with 16 fixed steps each) • Relay, logic, isolated analog outputs • Up to two TA inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU slave • RS485 serial communication in Modbus RTU master for reading/ writing information to Modbus slave devices • Ethernet Modbus TCP communication in Slave mode • Web server for browser access to web pages residing in the device, for monitoring and setting parameters • Bridge function for creation of Modbus RTU 485 sub-network • Weekly clock\calendar with RTC • Removable faceplate for immediate replacement • Accuracy 0,1%, sampling time 60 ms -

Features

Features- Operator interface with large LCD Display, customizable, with choice of colors

- Scrolling diagnostics messages, configurable, in the selected language

- Easy, guided configuration, copy/paste parameters even with power off

- Preventive maintenance with energy counters (kWh) and load switching

- 16 function block applications

- Timer, setpoint and algorithm programmer for controlling motorized valves

- Advanced tuning of control parameters

- Different password levels

- Universal input configurable for thermocouples, resistance thermometers, linear inputs

- Remote setpoint input

- Relay, logic, isolated analog outputs

- Up to two CT inputs for interrupted load diagnostics

- RS485 serial communication in Modbus RTU

- Removable faceplate for immediate replacement

- Sampling time 60ms

-

Features • Operator interface with large LCD Display, customizable, with choice of colors • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 16 function block applications • Timer, set point and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • Universal input configurable for thermocouples, resistance thermometers, linear inputs • Remote set point input • Relay, logic, isolated analog outputs • Up to two CT inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU • Removable faceplate for immediate replacement • Sampling time 60ms

Features • Operator interface with large LCD Display, customizable, with choice of colors • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 16 function block applications • Timer, set point and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • Universal input configurable for thermocouples, resistance thermometers, linear inputs • Remote set point input • Relay, logic, isolated analog outputs • Up to two CT inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU • Removable faceplate for immediate replacement • Sampling time 60ms -

Features • Operator interface with large LCD Display and three configurable bargraphs • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 32 function block applications • 8 Math application blocks • Timer, setpoint and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • 2 setpoint programmers (192 steps in 16 programs, or 12 programs with 16 fixed steps each) • 1 ingresso analogico lineare configurabile per funzioni ausiliarie • 2 PID control loops • 2 Programmatori di setpoint (192 passi in 16 programmi oppure 12 programmi da 16 passi fissi ciascuno) • Relay, logic, isolated analog outputs • Up to two TA inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU slave • RS485 serial communication in Modbus RTU master for reading/ writing information to Modbus slave devices • Ethernet Modbus TCP communication in Slave mode • Web server for browser access to web pages residing in the devvice, for monitoring and setting parameters • Bridge function for creation of Modbus RTU 485 sub-network • Weekly clock\calendar with RTC • Removable faceplate for immediate replacement • Accuracy 0,1%, sampling time 60 ms

Features • Operator interface with large LCD Display and three configurable bargraphs • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 32 function block applications • 8 Math application blocks • Timer, setpoint and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • 2 setpoint programmers (192 steps in 16 programs, or 12 programs with 16 fixed steps each) • 1 ingresso analogico lineare configurabile per funzioni ausiliarie • 2 PID control loops • 2 Programmatori di setpoint (192 passi in 16 programmi oppure 12 programmi da 16 passi fissi ciascuno) • Relay, logic, isolated analog outputs • Up to two TA inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU slave • RS485 serial communication in Modbus RTU master for reading/ writing information to Modbus slave devices • Ethernet Modbus TCP communication in Slave mode • Web server for browser access to web pages residing in the devvice, for monitoring and setting parameters • Bridge function for creation of Modbus RTU 485 sub-network • Weekly clock\calendar with RTC • Removable faceplate for immediate replacement • Accuracy 0,1%, sampling time 60 ms -

Features • Operator interface with large LCD Display, customizable, with choice of colors • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/ paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 16 function block applications • Timer, setpoint and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • Universal input configurable for thermocouples, resistance thermometers, linear inputs • Remote setpoint input • Relay, logic, isolated analog outputs • Up to two CT inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU • Removable faceplate for immediate replacement • Sampling time 60 ms

Features • Operator interface with large LCD Display, customizable, with choice of colors • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/ paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 16 function block applications • Timer, setpoint and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • Universal input configurable for thermocouples, resistance thermometers, linear inputs • Remote setpoint input • Relay, logic, isolated analog outputs • Up to two CT inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU • Removable faceplate for immediate replacement • Sampling time 60 ms -

Features • Operator interface with color touch screen display, 7” • Up to 16 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 250 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection

Features • Operator interface with color touch screen display, 7” • Up to 16 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 250 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection -

Features • Operator interface with color touch screen display, 3.5 “ • Up to 8 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 200 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Management of active and historic alarms • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection

Features • Operator interface with color touch screen display, 3.5 “ • Up to 8 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 200 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Management of active and historic alarms • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection -

Features • Universal input configurable from the faceplate • Acquisition of the input signal every 120msec ; resolution 30000steps • Two control outputs: relay, logic or analogue with Open/Close valve function • 3 configurable alarms • 2 analogue outputs (retransmission) • 2 digital inputs with configurable function • Auxiliary input for valve position potentiometer feedback • Heater Break or shortcircuit probe alarm • Self and Auto-tuning, Soft-start, Local/Remote setpoint, Auto/Man • Multiset function, timer set ramp

Features • Universal input configurable from the faceplate • Acquisition of the input signal every 120msec ; resolution 30000steps • Two control outputs: relay, logic or analogue with Open/Close valve function • 3 configurable alarms • 2 analogue outputs (retransmission) • 2 digital inputs with configurable function • Auxiliary input for valve position potentiometer feedback • Heater Break or shortcircuit probe alarm • Self and Auto-tuning, Soft-start, Local/Remote setpoint, Auto/Man • Multiset function, timer set ramp -

Features • Up to 16 inputs/16 outputs • For Temperature, Pressure, Flow, Level, RH, Conductivity, etc. • Various Input (X)/Output (Y) combinations : X4Y0, X4Y8, X8Y4, X8Y16, X16Y16, etc • Universal Input : 8 Thermocouples, Pt100, mV or mA input front panel selection without DIP for each channel • Front panel user calibration • Input burn protection • Non-volatile memory for parameters - no batteries • 3 key, 5 level programming • Setpoint and level locks • Tactile membrane keypad • 5 software versions : Indicator, Multisetpoint, Grouping, etc • RS485 with MODBUS RTU • Powerful, flexible SCADA software available • FDA21CFR Part11 compliant SCADA version also • Option : Printer interface (no computer needed) • 85~265 V AC SMPS or 24 V DC supply

Features • Up to 16 inputs/16 outputs • For Temperature, Pressure, Flow, Level, RH, Conductivity, etc. • Various Input (X)/Output (Y) combinations : X4Y0, X4Y8, X8Y4, X8Y16, X16Y16, etc • Universal Input : 8 Thermocouples, Pt100, mV or mA input front panel selection without DIP for each channel • Front panel user calibration • Input burn protection • Non-volatile memory for parameters - no batteries • 3 key, 5 level programming • Setpoint and level locks • Tactile membrane keypad • 5 software versions : Indicator, Multisetpoint, Grouping, etc • RS485 with MODBUS RTU • Powerful, flexible SCADA software available • FDA21CFR Part11 compliant SCADA version also • Option : Printer interface (no computer needed) • 85~265 V AC SMPS or 24 V DC supply -

Features • Upto 16 inputs/16 outputs • For Temperature, Pressure, Flow, Level, RH, Conductivity, etc. • Various Input (X)/Output (Y) combinations : X4Y0, X4Y8, X8Y4, X8Y16, X16Y16, etc • Universal Input : 8 Thermocouples, Pt100, mV or mA input front panel selection without DIP for each channel • Front panel user calibration • Input burn protection • Non-volatile memory for parameters - no batteries • 3 key, 5 level programming • Setpoint and level locks • Tactile membrane keypad • 5 software versions : Indicator, Multisetpoint, Grouping, etc • RS485 with MODBUS RTU • Powerful, flexible SCADA software available • FDA21CFR Part11 compliant SCADA version also • Option : Printer interface (no computer needed) • 85~265 V AC SMPS or 24 V DC supply

Features • Upto 16 inputs/16 outputs • For Temperature, Pressure, Flow, Level, RH, Conductivity, etc. • Various Input (X)/Output (Y) combinations : X4Y0, X4Y8, X8Y4, X8Y16, X16Y16, etc • Universal Input : 8 Thermocouples, Pt100, mV or mA input front panel selection without DIP for each channel • Front panel user calibration • Input burn protection • Non-volatile memory for parameters - no batteries • 3 key, 5 level programming • Setpoint and level locks • Tactile membrane keypad • 5 software versions : Indicator, Multisetpoint, Grouping, etc • RS485 with MODBUS RTU • Powerful, flexible SCADA software available • FDA21CFR Part11 compliant SCADA version also • Option : Printer interface (no computer needed) • 85~265 V AC SMPS or 24 V DC supply