- Zero-crossing voltage switching (ZC)

- Overtemperature protection

- Compact designs

-

Features

Features- Operator interface with large LCD Display,customizable, with choice of colors

- Scrolling diagnostics messages, configurable, in the selected language

- Easy, guided configuration, copy/paste parameters even with power off

- Preventive maintenance with energy counters (kWh) and load switching

- 16 function block applications

- Timer, setpoint and algorithm programmer for controlling motorized valves

- Advanced tuning of control parameters

- Different password levels

- Universal input configurable for thermocouples, resistance thermometers, linear inputs

- Remote setpoint input

- Relay, logic, isolated analog outputs

- CT inputs for interrupted load diagnostics

- RS485 serial communication in Modbus RTU

- Removable faceplate for immediate replacement

- Sampling time 60ms

- 10V power supply for potentiometer and 24V for transmitter

-

Features • Command input from analogue voltage or current signal or potentiometer. • Switching at voltage zero crossing. • Partialization of wave train power with dynamically optimized time cycle. • Antiparallel double SCR • 2 led for supply indication, “ON” state, 1 optional LED for load interrupt alarm • 4000V isolation between input circuit and power output • MOV (varistor) • Optional monitoring of interrupted load

Features • Command input from analogue voltage or current signal or potentiometer. • Switching at voltage zero crossing. • Partialization of wave train power with dynamically optimized time cycle. • Antiparallel double SCR • 2 led for supply indication, “ON” state, 1 optional LED for load interrupt alarm • 4000V isolation between input circuit and power output • MOV (varistor) • Optional monitoring of interrupted load -

Features • Command input from analogue voltage or current signal or potentiometer. • Switching at voltage zero crossing. • Partialization of wave train power with dynamically optimized time cycle. • Antiparallel double SCR • 2 led for supply indication, “ON” state, 1 optional LED for load interrupt alarm • 4000V isolation between input circuit and power output • MOV (varistor) • Optional monitoring of interrupted load

Features • Command input from analogue voltage or current signal or potentiometer. • Switching at voltage zero crossing. • Partialization of wave train power with dynamically optimized time cycle. • Antiparallel double SCR • 2 led for supply indication, “ON” state, 1 optional LED for load interrupt alarm • 4000V isolation between input circuit and power output • MOV (varistor) • Optional monitoring of interrupted load -

Features

Features- Operator interface with large LCD Display, customizable, with choice of colors

- Scrolling diagnostics messages, configurable, in the selected language

- Easy, guided configuration, copy/paste parameters even with power off

- Preventive maintenance with energy counters (kWh) and load switching

- 16 function block applications

- Timer, setpoint and algorithm programmer for controlling motorized valves

- Advanced tuning of control parameters

- Different password levels

- Universal input configurable for thermocouples, resistance thermometers, linear inputs

- Remote setpoint input

- Relay, logic, isolated analog outputs

- Up to two CT inputs for interrupted load diagnostics

- RS485 serial communication in Modbus RTU

- Removable faceplate for immediate replacement

- Sampling time 60ms

-

Features • Universal input configurable from the faceplate • Acquisition of the input signal every 120msec ; resolution 30000steps • Two control outputs: relay, logic or analogue with Open/Close valve function • 3 configurable alarms • 2 analogue outputs (retransmission) • 2 digital inputs with configurable function • Auxiliary input for valve position potentiometer feedback • Heater Break or shortcircuit probe alarm • Self and Auto-tuning, Soft-start, Local/Remote setpoint, Auto/Man • Multiset function, timer set ramp

Features • Universal input configurable from the faceplate • Acquisition of the input signal every 120msec ; resolution 30000steps • Two control outputs: relay, logic or analogue with Open/Close valve function • 3 configurable alarms • 2 analogue outputs (retransmission) • 2 digital inputs with configurable function • Auxiliary input for valve position potentiometer feedback • Heater Break or shortcircuit probe alarm • Self and Auto-tuning, Soft-start, Local/Remote setpoint, Auto/Man • Multiset function, timer set ramp -

Features • Operator interface with color touch screen display, 3.5 “ • Up to 8 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 200 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Management of active and historic alarms • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection

Features • Operator interface with color touch screen display, 3.5 “ • Up to 8 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 200 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Management of active and historic alarms • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection -

Features • Operator interface with color touch screen display, 7” • Up to 16 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 250 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection

Features • Operator interface with color touch screen display, 7” • Up to 16 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 250 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection -

Features • Operator interface with large LCD Display, customizable, with choice of colors • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/ paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 16 function block applications • Timer, setpoint and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • Universal input configurable for thermocouples, resistance thermometers, linear inputs • Remote setpoint input • Relay, logic, isolated analog outputs • Up to two CT inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU • Removable faceplate for immediate replacement • Sampling time 60 ms

Features • Operator interface with large LCD Display, customizable, with choice of colors • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/ paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 16 function block applications • Timer, setpoint and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • Universal input configurable for thermocouples, resistance thermometers, linear inputs • Remote setpoint input • Relay, logic, isolated analog outputs • Up to two CT inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU • Removable faceplate for immediate replacement • Sampling time 60 ms -

Features • Operator interface with large LCD Display and three configurable bargraphs • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 32 function block applications • 8 Math application blocks • Timer, setpoint and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • 2 setpoint programmers (192 steps in 16 programs, or 12 programs with 16 fixed steps each) • 1 ingresso analogico lineare configurabile per funzioni ausiliarie • 2 PID control loops • 2 Programmatori di setpoint (192 passi in 16 programmi oppure 12 programmi da 16 passi fissi ciascuno) • Relay, logic, isolated analog outputs • Up to two TA inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU slave • RS485 serial communication in Modbus RTU master for reading/ writing information to Modbus slave devices • Ethernet Modbus TCP communication in Slave mode • Web server for browser access to web pages residing in the devvice, for monitoring and setting parameters • Bridge function for creation of Modbus RTU 485 sub-network • Weekly clock\calendar with RTC • Removable faceplate for immediate replacement • Accuracy 0,1%, sampling time 60 ms

Features • Operator interface with large LCD Display and three configurable bargraphs • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 32 function block applications • 8 Math application blocks • Timer, setpoint and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • 2 setpoint programmers (192 steps in 16 programs, or 12 programs with 16 fixed steps each) • 1 ingresso analogico lineare configurabile per funzioni ausiliarie • 2 PID control loops • 2 Programmatori di setpoint (192 passi in 16 programmi oppure 12 programmi da 16 passi fissi ciascuno) • Relay, logic, isolated analog outputs • Up to two TA inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU slave • RS485 serial communication in Modbus RTU master for reading/ writing information to Modbus slave devices • Ethernet Modbus TCP communication in Slave mode • Web server for browser access to web pages residing in the devvice, for monitoring and setting parameters • Bridge function for creation of Modbus RTU 485 sub-network • Weekly clock\calendar with RTC • Removable faceplate for immediate replacement • Accuracy 0,1%, sampling time 60 ms -

Features • Operator interface with large LCD Display, customizable, with choice of colors • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 16 function block applications • Timer, set point and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • Universal input configurable for thermocouples, resistance thermometers, linear inputs • Remote set point input • Relay, logic, isolated analog outputs • Up to two CT inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU • Removable faceplate for immediate replacement • Sampling time 60ms

Features • Operator interface with large LCD Display, customizable, with choice of colors • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 16 function block applications • Timer, set point and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • Universal input configurable for thermocouples, resistance thermometers, linear inputs • Remote set point input • Relay, logic, isolated analog outputs • Up to two CT inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU • Removable faceplate for immediate replacement • Sampling time 60ms -

Features • Operator interface with large LCD Display and three configurable bargraphs • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even withe power off • Preventive maintenance with energy counters (kWh) and load switching • 32 function block applications • 8 Math application blocks • Timer, set point and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • 2 Universal inputs configurable for thermocouples, resistance thermometers, linear inputs • 1 linear analog input configurable for auxiliary functions • 2 PID control loops • 2 set point programmers (192 steps in 16 programs, or 12 programs with 16 fixed steps each) • Relay, logic, isolated analog outputs • Up to two TA inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU slave • RS485 serial communication in Modbus RTU master for reading/ writing information to Modbus slave devices • Ethernet Modbus TCP communication in Slave mode • Web server for browser access to web pages residing in the device, for monitoring and setting parameters • Bridge function for creation of Modbus RTU 485 sub-network • Weekly clock\calendar with RTC • Removable faceplate for immediate replacement • Accuracy 0,1%, sampling time 60 ms

Features • Operator interface with large LCD Display and three configurable bargraphs • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even withe power off • Preventive maintenance with energy counters (kWh) and load switching • 32 function block applications • 8 Math application blocks • Timer, set point and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • 2 Universal inputs configurable for thermocouples, resistance thermometers, linear inputs • 1 linear analog input configurable for auxiliary functions • 2 PID control loops • 2 set point programmers (192 steps in 16 programs, or 12 programs with 16 fixed steps each) • Relay, logic, isolated analog outputs • Up to two TA inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU slave • RS485 serial communication in Modbus RTU master for reading/ writing information to Modbus slave devices • Ethernet Modbus TCP communication in Slave mode • Web server for browser access to web pages residing in the device, for monitoring and setting parameters • Bridge function for creation of Modbus RTU 485 sub-network • Weekly clock\calendar with RTC • Removable faceplate for immediate replacement • Accuracy 0,1%, sampling time 60 ms -

Features • Operator interface with large LCD Display, customizable, with choice of colors • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 16 function block applications • Timer, set point and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • Universal input configurable for thermocouples, resistance thermometers, linear inputs • Remote set point input • Relay, logic, isolated analog outputs • Up to two CT inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU • Removable faceplate for immediate replacement • Sampling time 60ms

Features • Operator interface with large LCD Display, customizable, with choice of colors • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 16 function block applications • Timer, set point and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • Universal input configurable for thermocouples, resistance thermometers, linear inputs • Remote set point input • Relay, logic, isolated analog outputs • Up to two CT inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU • Removable faceplate for immediate replacement • Sampling time 60ms -

Features • Universal input configurable from faceplate • Accuracy better than 0.2% f.s. under nominal conditions • Control output: relay, logic, Triac or continuous • Hot/cold function with selection of cooling fluid • 3 alarms with completely configurable function • Analog retransmission output • Up to 2 isolated digital inputs with configurable function • Isolated digital input with configurable function • Auxiliary input for CT (TA) (50mAac) • Heater break or probe short-circuit alarm • Self-tuning, Auto-tuning, Soft-start, bumpless Man/Auto function • Double set, set ramp, timed output function • Optically isolated RS485 serial line. Protocol: GEFRAN MODBUS RTU • Self-diagnosis • Rapid configuration from PC with Winstrum packet

Features • Universal input configurable from faceplate • Accuracy better than 0.2% f.s. under nominal conditions • Control output: relay, logic, Triac or continuous • Hot/cold function with selection of cooling fluid • 3 alarms with completely configurable function • Analog retransmission output • Up to 2 isolated digital inputs with configurable function • Isolated digital input with configurable function • Auxiliary input for CT (TA) (50mAac) • Heater break or probe short-circuit alarm • Self-tuning, Auto-tuning, Soft-start, bumpless Man/Auto function • Double set, set ramp, timed output function • Optically isolated RS485 serial line. Protocol: GEFRAN MODBUS RTU • Self-diagnosis • Rapid configuration from PC with Winstrum packet -

Features • Universal input configurable from faceplate • Accuracy better than 0.2% f.s. under nominal conditions • Control output: relay, logic, Triac , continuous, digital insulated • Hot/cold function with selection of cooling fluid • 3 alarms with completely configurable function • Analog retransmission output • Isolated digital input with configurable function • Auxiliary input for CT (TA) (50mAac) • Heater break or probe short-circuit alarm • Self-tuning, Auto-tuning, Soft-start, bumpless Man/Auto function • Double set, set ramp, timed output function • Optically isolated RS485 serial line.Protocol: GEFRAN CENCAL or MODBUS RTU • Self-diagnosis • Rapid configuration from PC with Winstrum packet

Features • Universal input configurable from faceplate • Accuracy better than 0.2% f.s. under nominal conditions • Control output: relay, logic, Triac , continuous, digital insulated • Hot/cold function with selection of cooling fluid • 3 alarms with completely configurable function • Analog retransmission output • Isolated digital input with configurable function • Auxiliary input for CT (TA) (50mAac) • Heater break or probe short-circuit alarm • Self-tuning, Auto-tuning, Soft-start, bumpless Man/Auto function • Double set, set ramp, timed output function • Optically isolated RS485 serial line.Protocol: GEFRAN CENCAL or MODBUS RTU • Self-diagnosis • Rapid configuration from PC with Winstrum packet -

Features • Universal input configurable from faceplate • Accuracy better than 0.2% f.s. under nominal conditions • Control output: relay, logic, Triac , continuous, digital insulated • Hot/cold function with selection of cooling fluid • 3 alarms with completely configurable function • Analog retransmission output • Isolated digital input with configurable function • Auxiliary input for CT (TA) (50mAac) • Heater break or probe short-circuit alarm • Self-tuning, Auto-tuning, Soft-start, bumpless Man/Auto function • Double set, set ramp, timed output function • Optically isolated RS485 serial line. Protocol: GEFRAN CENCAL or MODBUS RTU • Self-diagnosis • Rapid configuration from PC with Winstrum packet

Features • Universal input configurable from faceplate • Accuracy better than 0.2% f.s. under nominal conditions • Control output: relay, logic, Triac , continuous, digital insulated • Hot/cold function with selection of cooling fluid • 3 alarms with completely configurable function • Analog retransmission output • Isolated digital input with configurable function • Auxiliary input for CT (TA) (50mAac) • Heater break or probe short-circuit alarm • Self-tuning, Auto-tuning, Soft-start, bumpless Man/Auto function • Double set, set ramp, timed output function • Optically isolated RS485 serial line. Protocol: GEFRAN CENCAL or MODBUS RTU • Self-diagnosis • Rapid configuration from PC with Winstrum packet -

Features • Operator interface with color touch screen display, 7” • Up to 16 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 250 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection

Features • Operator interface with color touch screen display, 7” • Up to 16 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 250 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection -

Features • Operator interface with color touch screen display, 3.5 “ • Up to 8 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 200 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Management of active and historic alarms • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection

Features • Operator interface with color touch screen display, 3.5 “ • Up to 8 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 200 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Management of active and historic alarms • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection -

Features • Interface module integrated in the connector • Standard output 0...10Vdc (PCIR 101) • Standard output 4...20mA(PCIR 102) • High linearity • Adjustable Zero and Span • Low zero and span thermal drift • 4 pole female DIN43650 connector for LTM and PKM potentiometer • DIN 43650 4-pin female connector for direct connection to LTM and PKM potentiometers (the DIN 43650 connector in the PCM series is smaller and cannot be connected directly)

Features • Interface module integrated in the connector • Standard output 0...10Vdc (PCIR 101) • Standard output 4...20mA(PCIR 102) • High linearity • Adjustable Zero and Span • Low zero and span thermal drift • 4 pole female DIN43650 connector for LTM and PKM potentiometer • DIN 43650 4-pin female connector for direct connection to LTM and PKM potentiometers (the DIN 43650 connector in the PCM series is smaller and cannot be connected directly) -

Features • Sealed industrial version • Independent linearity up to ± 0,05% (standard ± 0,5%) • Working temperature: -55...+100°C • Repetibility 0,01% della C.E.T. • Life duration: >100x106 operations at 10 r.p.s. (within C.E.U.) • Infinite resolution • Electrical connection: 5-pole connector DIN 43322 • Grade of protection IP65 • Suitable for use in explosive environments with presence of gas (groups IIA, IIB, IIC) and combustible powders. Standards for simple device: ATEX CEI EN 50020 2003 - paragraph 5.4 a

Features • Sealed industrial version • Independent linearity up to ± 0,05% (standard ± 0,5%) • Working temperature: -55...+100°C • Repetibility 0,01% della C.E.T. • Life duration: >100x106 operations at 10 r.p.s. (within C.E.U.) • Infinite resolution • Electrical connection: 5-pole connector DIN 43322 • Grade of protection IP65 • Suitable for use in explosive environments with presence of gas (groups IIA, IIB, IIC) and combustible powders. Standards for simple device: ATEX CEI EN 50020 2003 - paragraph 5.4 a -

Features • Models 09, 11, 20 • Servo mounting • Independent linearity up to ± 0,05% (standard ± 0,5%) • Repetibility 0,01% C.E.T. • Rotation speed ≤ 600 r.p.m. (within C.E.U.) • Life duration: >100x106 operations at 10 r.p.s. • Infinite resolution • Electrical terminals: turrets • Grade of protection IP40 • Suitable for use in explosive environments with presence of gas (groups IIA, IIB, IIC) and combustible powders. Standards for simple device: ATEX CEI EN 50020 2003 - paragraph 5.4 a

Features • Models 09, 11, 20 • Servo mounting • Independent linearity up to ± 0,05% (standard ± 0,5%) • Repetibility 0,01% C.E.T. • Rotation speed ≤ 600 r.p.m. (within C.E.U.) • Life duration: >100x106 operations at 10 r.p.s. • Infinite resolution • Electrical terminals: turrets • Grade of protection IP40 • Suitable for use in explosive environments with presence of gas (groups IIA, IIB, IIC) and combustible powders. Standards for simple device: ATEX CEI EN 50020 2003 - paragraph 5.4 a -

Principal Characteristics • Transducer with exposed tracks, allowing rod diameter is reduced to be reduced to a minimum to permit installation in small cylinders. • Thanks to a special constructive technique, the IC transducer provides high resistance to the working pressures of oil-pressure cylinders (max 340 bar) • Available with internal flanges or external threads to guarantee mechanical compatibility with all principal cylinder types.

Principal Characteristics • Transducer with exposed tracks, allowing rod diameter is reduced to be reduced to a minimum to permit installation in small cylinders. • Thanks to a special constructive technique, the IC transducer provides high resistance to the working pressures of oil-pressure cylinders (max 340 bar) • Available with internal flanges or external threads to guarantee mechanical compatibility with all principal cylinder types. -

Applicative Characteristics • The PMI-SLE transducer, is the amplified version of the PMI-SL, a product designed for all inside cylinder applications which require a smaller transducer (the rod diameter is only 12,7 mm). • The PMI Slim offers the same robustness: stainlessteel body, IP67 protection level, and pressure resistance up to 250 bar (400 bar peak) • Available with flanged or threaded heads, to guarantee mechanical compatibility with all main cylinder types • Patented solution • Ideal for applications inside hydraulic cylinders, demanding simple solutions which guarantee measurement repeatability.

Applicative Characteristics • The PMI-SLE transducer, is the amplified version of the PMI-SL, a product designed for all inside cylinder applications which require a smaller transducer (the rod diameter is only 12,7 mm). • The PMI Slim offers the same robustness: stainlessteel body, IP67 protection level, and pressure resistance up to 250 bar (400 bar peak) • Available with flanged or threaded heads, to guarantee mechanical compatibility with all main cylinder types • Patented solution • Ideal for applications inside hydraulic cylinders, demanding simple solutions which guarantee measurement repeatability. -

Applicative Characteristics • The PMI-SL transducer, an evolution of the PMI-12, is designed for all inside cylinder applications which require a smaller transducer. For this reason, the diameter has been reduced to 12.7 mm. • The PMI Slim offers the same robustness as the PMI-12: AISI 316 stainless steel body, IP67 protection level, and pressure resistance up to 250 bar (400 bar peak) • Available with flanged or threaded heads, to guarantee mechanical compatibility with all main cylinder types • Patented solution • Ideal for applications inside hydraulic cylinders, demanding simple solutions which guarantee measurement repeatability

Applicative Characteristics • The PMI-SL transducer, an evolution of the PMI-12, is designed for all inside cylinder applications which require a smaller transducer. For this reason, the diameter has been reduced to 12.7 mm. • The PMI Slim offers the same robustness as the PMI-12: AISI 316 stainless steel body, IP67 protection level, and pressure resistance up to 250 bar (400 bar peak) • Available with flanged or threaded heads, to guarantee mechanical compatibility with all main cylinder types • Patented solution • Ideal for applications inside hydraulic cylinders, demanding simple solutions which guarantee measurement repeatability -

Main Characteristics • The PMI-12 transducer is designed for use inside oil pressure cylinders, applications that demand high strength. • The AISI316 stainless steel body and elevated protection level permit installation in cylinders with pressures up to 250 bar (400 bar peak). • Available with internal flanges or external threads to guarantee mechanical compatibility with all principal cylinder types. • Patented

Main Characteristics • The PMI-12 transducer is designed for use inside oil pressure cylinders, applications that demand high strength. • The AISI316 stainless steel body and elevated protection level permit installation in cylinders with pressures up to 250 bar (400 bar peak). • Available with internal flanges or external threads to guarantee mechanical compatibility with all principal cylinder types. • Patented -

Principal Characteristics • The PMA-12 transducer, a development of the PME series, is designed for installation with self-aligning joints. • The IP67 protection level makes the PMA-12 highly suitable for humid and wet environments and in temporary immersion (CEI EN 60529). • Available only with cable output. • Ideal for applications on metalworking and ceramics machines, as well as on earth-moving machines and utility vehicles. Recommended in all cases where the angle of the drive axle changes constantly.

Principal Characteristics • The PMA-12 transducer, a development of the PME series, is designed for installation with self-aligning joints. • The IP67 protection level makes the PMA-12 highly suitable for humid and wet environments and in temporary immersion (CEI EN 60529). • Available only with cable output. • Ideal for applications on metalworking and ceramics machines, as well as on earth-moving machines and utility vehicles. Recommended in all cases where the angle of the drive axle changes constantly. -

Features • Rectilinear displacement transducer without drag shaft, completely water-tight (IP67), designed to work in humid environments (CEI EN 60529) • The PME series has an external magnetic actuator linked to an internal measurement cursor • The magnetic cursor replaces the drag shaft used in traditional displacement transducers, making the instrument even more compact • Installation is made simpler because there is no variation in the electrical output signal outside the Theoretical Electrical Stroke • The instrument can be used in compressed air applications with max. working pressure of 20 bar.

Features • Rectilinear displacement transducer without drag shaft, completely water-tight (IP67), designed to work in humid environments (CEI EN 60529) • The PME series has an external magnetic actuator linked to an internal measurement cursor • The magnetic cursor replaces the drag shaft used in traditional displacement transducers, making the instrument even more compact • Installation is made simpler because there is no variation in the electrical output signal outside the Theoretical Electrical Stroke • The instrument can be used in compressed air applications with max. working pressure of 20 bar. -

Features • This transducer is designed to guarantee a high protection level (IP67) in applications under harsh conditions and outdoors, where it may be necessary to work in the direct presence of dust, dirt, or liquids (not in prolonged immersion) • Its high protection level and very small size make the PZ67-A unique in terms of reliability and flexible installation • It is ideal for glass cutting and washing machines or for honers and sanders if there is direct exposure to liquids or even just steam • Indicated for test and bench equipment, especially if outdoors

Features • This transducer is designed to guarantee a high protection level (IP67) in applications under harsh conditions and outdoors, where it may be necessary to work in the direct presence of dust, dirt, or liquids (not in prolonged immersion) • Its high protection level and very small size make the PZ67-A unique in terms of reliability and flexible installation • It is ideal for glass cutting and washing machines or for honers and sanders if there is direct exposure to liquids or even just steam • Indicated for test and bench equipment, especially if outdoors -

Features • This transducer is designed to guarantee a high protection level (IP67) in applications under harsh conditions and outdoors, where it may be necessary to work in the direct presence of dust, dirt, or liquids (not in prolonged immersion) • Its high protection level and very small size make the PZ67-S unique in terms of reliability and flexible installation • It is ideal for glass cutting and washing machines or for honers and sanders if there is direct exposure to liquids or even just steam • Indicated for test and bench equipment, especially if outdoors

Features • This transducer is designed to guarantee a high protection level (IP67) in applications under harsh conditions and outdoors, where it may be necessary to work in the direct presence of dust, dirt, or liquids (not in prolonged immersion) • Its high protection level and very small size make the PZ67-S unique in terms of reliability and flexible installation • It is ideal for glass cutting and washing machines or for honers and sanders if there is direct exposure to liquids or even just steam • Indicated for test and bench equipment, especially if outdoors -

Principal Characteristics • The 3/4” cylindrical housing, plus the option of all fastening systems (brackets, joints or flange), makes the PZ34 series highly versatile for a wide range of applications. • The optimized mechanical structure makes the product suitable for developing various special executions (contact Gefran customer service for details). • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • Ideal for wood and glass working and finishing machines and for car test benches.

Principal Characteristics • The 3/4” cylindrical housing, plus the option of all fastening systems (brackets, joints or flange), makes the PZ34 series highly versatile for a wide range of applications. • The optimized mechanical structure makes the product suitable for developing various special executions (contact Gefran customer service for details). • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • Ideal for wood and glass working and finishing machines and for car test benches. -

Principal Characteristics • The 1/2” cylindrical housing, plus the option of all fastening systems (brackets, joints or flange), makes the PZ12 series highly versatile for a wide range of applications. • The optimized mechanical structure makes the product suitable for developing various special executions (contact Gefran customer service for details). • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • Ideal for wood and glass working and finishing machines and for car test benches.

Principal Characteristics • The 1/2” cylindrical housing, plus the option of all fastening systems (brackets, joints or flange), makes the PZ12 series highly versatile for a wide range of applications. • The optimized mechanical structure makes the product suitable for developing various special executions (contact Gefran customer service for details). • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • Ideal for wood and glass working and finishing machines and for car test benches. -

Principal Characteristics • The side connection creates a through-rod structure with double rod support, guaranteeing greater overall strength of the transducer. • The return spring automatically returns the rod to zero position, making the transducer suitable for comparator applications. • The tip with roller bearing is suitable for applications where the object to be measured may be subject to shifts transverse to the transducer axle (shaft is prevented from rotating). • Ideal for checking the flatness or thickness of panels of various materials. Can also be used for valves or mechanical parts when the rod cannot be attached to the moving object

Principal Characteristics • The side connection creates a through-rod structure with double rod support, guaranteeing greater overall strength of the transducer. • The return spring automatically returns the rod to zero position, making the transducer suitable for comparator applications. • The tip with roller bearing is suitable for applications where the object to be measured may be subject to shifts transverse to the transducer axle (shaft is prevented from rotating). • Ideal for checking the flatness or thickness of panels of various materials. Can also be used for valves or mechanical parts when the rod cannot be attached to the moving object -

Principal Characteristics • The side connection creates a through-rod structure with double rod support, guaranteeing greater overall strength of the transducer. • The return spring automatically returns the rod to zero position, making the transducer suitable for comparator applications. • The tip with stainless steel ball is suitable for applications where the object to be measured is not subject to shifts transverse to the transducer axle. • Ideal for checking the flatness or thickness of panels of various materials. Can also be used for valves or mechanical parts when the rod cannot be attached to the moving object.

Principal Characteristics • The side connection creates a through-rod structure with double rod support, guaranteeing greater overall strength of the transducer. • The return spring automatically returns the rod to zero position, making the transducer suitable for comparator applications. • The tip with stainless steel ball is suitable for applications where the object to be measured is not subject to shifts transverse to the transducer axle. • Ideal for checking the flatness or thickness of panels of various materials. Can also be used for valves or mechanical parts when the rod cannot be attached to the moving object. -

Principal Characteristics • The transducer’s compactness makes it suitable for installation in small spaces and for detecting small shifts. • The side connection creates a through-rod structure with double rod support, guaranteeing greater overall strength of the transducer. • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • Ideal for small mechanical devices, valves, and test tools and benches.

Principal Characteristics • The transducer’s compactness makes it suitable for installation in small spaces and for detecting small shifts. • The side connection creates a through-rod structure with double rod support, guaranteeing greater overall strength of the transducer. • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • Ideal for small mechanical devices, valves, and test tools and benches. -

Principal Characteristics • The transducer’s compactness makes it suitable for installation in small spaces and for detecting small shifts. • The joint with up-take of slack and M4 threading provides greater tolerances in movement. • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • Ideal for small mechanical devices, valves, and test tools and benches.

Principal Characteristics • The transducer’s compactness makes it suitable for installation in small spaces and for detecting small shifts. • The joint with up-take of slack and M4 threading provides greater tolerances in movement. • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • Ideal for small mechanical devices, valves, and test tools and benches. -

Applicative Characteristics • The PC67 displacement transducer was developed to guarantee a high protection level (IP67) in applications under harsh conditions and outdoors, where it may be necessary to work in the presence of dust, dirt, or liquids (not in prolonged immersion). • The robust structure of the PC series has been improved thanks to a sealing system (patent pending) that makes it extremely reliable. • Ideal for mobile hydraulic applications, on agricultural machines, earth-moving equipment and utility vehicles

Applicative Characteristics • The PC67 displacement transducer was developed to guarantee a high protection level (IP67) in applications under harsh conditions and outdoors, where it may be necessary to work in the presence of dust, dirt, or liquids (not in prolonged immersion). • The robust structure of the PC series has been improved thanks to a sealing system (patent pending) that makes it extremely reliable. • Ideal for mobile hydraulic applications, on agricultural machines, earth-moving equipment and utility vehicles -

Features • This transducer is designed to guarantee a high protection level (IP67) in applications under harsh conditions and outdoors, where it may be necessary to work in the direct presence of dust, dirt, or liquids (not in prolonged immersion) • The grooves on the profile provide an excellent alternative to the usual system of fastening with brackets • Ideal for applications on plastic injection presses with installation at points that are highly exposed to lubricants • Also indicated for processing machines on which the transducer cannot be protected by guards

Features • This transducer is designed to guarantee a high protection level (IP67) in applications under harsh conditions and outdoors, where it may be necessary to work in the direct presence of dust, dirt, or liquids (not in prolonged immersion) • The grooves on the profile provide an excellent alternative to the usual system of fastening with brackets • Ideal for applications on plastic injection presses with installation at points that are highly exposed to lubricants • Also indicated for processing machines on which the transducer cannot be protected by guards -

Features • The transducer has been improved in order to guarantee greater reliability under all conditions • Mechanical linkage using joint with take up of play, M5 thread • Installation is made simpler by the absence of electrical signal variation in output, outside the Theoretical Electrical Stroke • The new grooves provide an excellent alternative to the usual system of fastening with brackets • Ideal for applications on plastic injection presses, vertical presses, and on many other processing machines • Grade of protection IP40

Features • The transducer has been improved in order to guarantee greater reliability under all conditions • Mechanical linkage using joint with take up of play, M5 thread • Installation is made simpler by the absence of electrical signal variation in output, outside the Theoretical Electrical Stroke • The new grooves provide an excellent alternative to the usual system of fastening with brackets • Ideal for applications on plastic injection presses, vertical presses, and on many other processing machines • Grade of protection IP40 -

Principal Characteristics • The transducer is designed to satisfy extreme applicative demands in terms of mechanical strength. • The 10 mm diameter rod, large steel joints, and reinforced structure make this series mechanically ideal for Metal working, woodworking, and ceramics. • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • The structure based on self-aligning and weight-bearing ball joints permits assembly with free movement of the transducer axle

Principal Characteristics • The transducer is designed to satisfy extreme applicative demands in terms of mechanical strength. • The 10 mm diameter rod, large steel joints, and reinforced structure make this series mechanically ideal for Metal working, woodworking, and ceramics. • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • The structure based on self-aligning and weight-bearing ball joints permits assembly with free movement of the transducer axle -

Features • Current sizes 16, 32, 40 Amps per channel • Integrated current transformers • Fuses with fuse-holder disconnectors on the front (option) • 4 universal process inputs ( TC, RTD, mA, V ) • 4 independent hot/cold PIDs • 4 main outputs (directly connected to the static unit) • 4 auxiliary analogue inputs (option) • 4 settable outputs (option): relay/logic/TRIAC/analogue • 2 settable relay outputs • 2 settable digital inputs • Modbus RTU communication port • Communication port for Fieldbus (option): Profinet, Profibus DP, Ethernet IP, EtherCAT, Modbus TCP/RTU, CANopen, DeviceNET • ODVA (Ethernet/IP) and PI (ProfiNET) certification • DIN rail or panel mounting • CE, UL, CSA certifications and SCCR UL 508 100KA approval

Features • Current sizes 16, 32, 40 Amps per channel • Integrated current transformers • Fuses with fuse-holder disconnectors on the front (option) • 4 universal process inputs ( TC, RTD, mA, V ) • 4 independent hot/cold PIDs • 4 main outputs (directly connected to the static unit) • 4 auxiliary analogue inputs (option) • 4 settable outputs (option): relay/logic/TRIAC/analogue • 2 settable relay outputs • 2 settable digital inputs • Modbus RTU communication port • Communication port for Fieldbus (option): Profinet, Profibus DP, Ethernet IP, EtherCAT, Modbus TCP/RTU, CANopen, DeviceNET • ODVA (Ethernet/IP) and PI (ProfiNET) certification • DIN rail or panel mounting • CE, UL, CSA certifications and SCCR UL 508 100KA approval -

Features • Command input from analogue voltage or current signal or potentiometer. • Switching at voltage zero crossing. • Partialization of wave train power with dynamically optimized time cycle. • Antiparallel double SCR • 2 led for supply indication, “ON” state, 1 optional LED for load interrupt alarm • 4000V isolation between input circuit and power output • MOV (varistor) • Optional monitoring of interrupted load • DIN rail mounting (standard); Panel mounting (optional)

Features • Command input from analogue voltage or current signal or potentiometer. • Switching at voltage zero crossing. • Partialization of wave train power with dynamically optimized time cycle. • Antiparallel double SCR • 2 led for supply indication, “ON” state, 1 optional LED for load interrupt alarm • 4000V isolation between input circuit and power output • MOV (varistor) • Optional monitoring of interrupted load • DIN rail mounting (standard); Panel mounting (optional) -

Features • Pressure ranges from: 0-17 to 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FS (H); < ±0.5% FS (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). • SIL2 and PL d approvals for Functional Safety • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi (up to 400°C/750°F) • Stem material: 17-4 PH

Features • Pressure ranges from: 0-17 to 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FS (H); < ±0.5% FS (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). • SIL2 and PL d approvals for Functional Safety • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi (up to 400°C/750°F) • Stem material: 17-4 PH -

Features • Pressure ranges from: 0-17 to 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FS (H); < ±0.5% FS (M) • “Mercury free” hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi up to 400°C (750°F) • Stem material: 17-4 PH • IO-Link output, ready for “Industry 4.0” • Rangeabilty: 3:1 • PLd and SIL2 approvals for Functional safety • Autozero function • Auxiliary information over IO-Link protocol

Features • Pressure ranges from: 0-17 to 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FS (H); < ±0.5% FS (M) • “Mercury free” hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi up to 400°C (750°F) • Stem material: 17-4 PH • IO-Link output, ready for “Industry 4.0” • Rangeabilty: 3:1 • PLd and SIL2 approvals for Functional safety • Autozero function • Auxiliary information over IO-Link protocol -

Features • Pressure ranges from: 0-17 ato 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FSO (H); < ±0.5% FSO (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. NaK is defined as a safe substance (GRAS). • Quantity of NaK contained per model: K70 series (30mm³) [0.00183 in³], K71, K72, K73 (40mm³) [0.00244 in³] • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100 bar-1500 psi up to 400°C (750°F) • Material of stem 17-4PH

Features • Pressure ranges from: 0-17 ato 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FSO (H); < ±0.5% FSO (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. NaK is defined as a safe substance (GRAS). • Quantity of NaK contained per model: K70 series (30mm³) [0.00183 in³], K71, K72, K73 (40mm³) [0.00244 in³] • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100 bar-1500 psi up to 400°C (750°F) • Material of stem 17-4PH -

Features • Pressure ranges from: 0-17 to 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FSO (H); < ±0.5% FSO (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. NaK is defined as a safe substance (GRAS) • Quantity of NaK contained per model: KE0 series (30mm³) [0.00183 in³], KE1, KE2, KE3 (40mm³) [0.00244 in³] • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi up to 400°C (750°F) • Stem material: 17-4 PH

Features • Pressure ranges from: 0-17 to 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FSO (H); < ±0.5% FSO (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. NaK is defined as a safe substance (GRAS) • Quantity of NaK contained per model: KE0 series (30mm³) [0.00183 in³], KE1, KE2, KE3 (40mm³) [0.00244 in³] • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi up to 400°C (750°F) • Stem material: 17-4 PH -

Features • Pressure ranges from: 0-17 to 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FS (H); < ±0.5% FS (M) • SIL2 approvals for Functional Safety • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Stem drift Auto compensation function (SP version) • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100 bar-1500 psi up to 400°C (750°F) • Material of stem 17-4PH

Features • Pressure ranges from: 0-17 to 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FS (H); < ±0.5% FS (M) • SIL2 approvals for Functional Safety • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Stem drift Auto compensation function (SP version) • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100 bar-1500 psi up to 400°C (750°F) • Material of stem 17-4PH -

Features • Pressure ranges from: 0-17 to 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FS (H); < ±0.5% FS (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. • SIL2 approvals for Functional Safety • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Stem drift Auto compensation function (SP version) • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi up to 400°C (750°F) • Stem material: 17-4 PH

Features • Pressure ranges from: 0-17 to 0-1000 bar / 0-250 to 0-15000 psi • Accuracy: < ±0.25% FS (H); < ±0.5% FS (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. • SIL2 approvals for Functional Safety • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Stem drift Auto compensation function (SP version) • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi up to 400°C (750°F) • Stem material: 17-4 PH -

Features Electrical • Digital output signal with DP404 CAN OPEN communication protocol • Transmission frequency (Baud rate): 10 Kbaud to 1Mbaud (default 500 Kbaud) • Software selection of Baud rate and ID nodes • Operation with 1 or 2 settable alarm limits • “Autozero” for temperature compensation • 80% FSO calibration signal

Features Electrical • Digital output signal with DP404 CAN OPEN communication protocol • Transmission frequency (Baud rate): 10 Kbaud to 1Mbaud (default 500 Kbaud) • Software selection of Baud rate and ID nodes • Operation with 1 or 2 settable alarm limits • “Autozero” for temperature compensation • 80% FSO calibration signal -

Features • Pressure ranges from: 0-35 to 0-1000 bar / 0-500 to 0-15000 psi • Accuracy: < ±0.25% FSO (H); < ±0.5% FSO (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. NaK is defined as a safe substance (GRAS). • Quantity of NaK contained per model: KN0 series (30mm3) [0.00183 in3], KN1, KN2, KN3 (40mm3) [0.00244 in3] • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Stem drift Auto compensation function (SP version) • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100 bar-1500 psi up to 400°C (750°F) • Material of stem 17-4PH

Features • Pressure ranges from: 0-35 to 0-1000 bar / 0-500 to 0-15000 psi • Accuracy: < ±0.25% FSO (H); < ±0.5% FSO (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. NaK is defined as a safe substance (GRAS). • Quantity of NaK contained per model: KN0 series (30mm3) [0.00183 in3], KN1, KN2, KN3 (40mm3) [0.00244 in3] • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Stem drift Auto compensation function (SP version) • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100 bar-1500 psi up to 400°C (750°F) • Material of stem 17-4PH -

Features • Pressure ranges from: 0-35 to 0-1000 bar / 0-500 to 0-15000 psi • Accuracy <±0.25% FSO (H); <±0.5% FSO (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. NaK is defined as a safe substance (GRAS • Quantity of NaK contained per model: K30 series (30mm³) [0.00183 in³], K31-K32-K33 series (40mm³) [0.00244 in³] • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi up to 400°C (750°F) • Stem material: 17-4 PH

Features • Pressure ranges from: 0-35 to 0-1000 bar / 0-500 to 0-15000 psi • Accuracy <±0.25% FSO (H); <±0.5% FSO (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. NaK is defined as a safe substance (GRAS • Quantity of NaK contained per model: K30 series (30mm³) [0.00183 in³], K31-K32-K33 series (40mm³) [0.00244 in³] • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi up to 400°C (750°F) • Stem material: 17-4 PH -

Features • Pressure ranges from: 0-35 to 0-1000 bar / 0-500 to 0-15000 psi • Accuracy: < ±0.25% FSO (H); < ±0.5% FSO (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. NaK is defined as a safe substance (GRAS) • Quantity of NaK contained per model: KE0 series (30mm³) [0.00183 in³], KE1, KE2, KE3 (40mm³) [0.00244 in³] • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Stem drift Auto compensation function (SP version) • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi up to 400°C (750°F) • Stem material: 17-4 PH

Features • Pressure ranges from: 0-35 to 0-1000 bar / 0-500 to 0-15000 psi • Accuracy: < ±0.25% FSO (H); < ±0.5% FSO (M) • Hydraulic transmission system for pressure signal guarantees stability at working temperature (NaK). Liquid conforming to RoHS Directive. NaK is defined as a safe substance (GRAS) • Quantity of NaK contained per model: KE0 series (30mm³) [0.00183 in³], KE1, KE2, KE3 (40mm³) [0.00244 in³] • 1/2-20UNF, M18x1.5 standard threads; other types available on request • Autozero function on board / external option • Stem drift Auto compensation function (SP version) • Inconel 718 diaphragm with GTP+ coating for temperatures up to 538°C (1000°F) • 15-5 PH diaphragm with GTP+ coating for temperatures up to 400°C (750°F) • Hastelloy C276 diaphragm for temperatures up to 300°C (570°F) • 17-7 PH corrugated diaphragm with GTP+ coating for ranges below 100bar-1500psi up to 400°C (750°F) • Stem material: 17-4 PH -

Features

Features- Measurement range : ±10° ±15° ±20° ±30° ±45° ±60° ±85° (dual axis XY); 360° (±180°) (single axis Z)

- Supply voltage: +5Vdc (only for 0.5..4.5Vdc output); +10…+36Vdc (see output signal for right supply voltage)

- Output signal: 0.5...4.5V RATIOMETRIC (supply +5Vdc); 0.5...4.5V; 0...10V; 4...20mA; CANopen

- Electrical connections: AMP Superseal 6P 282108-1; 6 wires output 18 AWG 1.65mm OD (cable+connector on request)

- Resolution: 0.05° (±10° to ±20°); 0.05°(±30°); 0.1°(±45°); 0.1°(±60°); 0.1°(±85°); 0.1° (±180°) analog output; 0.05° CANopen output

-

Features • Measurement range: ±180° - different values on request programmable in steps of ±15° (ONLY for analogue versions) • Supply voltage: +5Vdc (only for 0.5..4.5Vdc output); +9…+36Vdc (see output signal for right supply voltage) • Output signal: 0.5...4.5V RATIOMETRIC (supply +5Vdc); 0.5...4.5V; 0...10V; 4...20mA; CANopen, SAE J1939 • Electrical connections: AMP Superseal 6P 282108-1; cable output 18 AWG 1.65mm OD • Resolution and speed of rotation: 12 bit (analog output); 14 bit (CANopen/SAE J1939 output); 120 rpm max. • Linearity: < ±0.5%FS • Working and coefficient temperature: -40°C ... +85°C (higher values on request); thermal drift < 50 ppm/°C

Features • Measurement range: ±180° - different values on request programmable in steps of ±15° (ONLY for analogue versions) • Supply voltage: +5Vdc (only for 0.5..4.5Vdc output); +9…+36Vdc (see output signal for right supply voltage) • Output signal: 0.5...4.5V RATIOMETRIC (supply +5Vdc); 0.5...4.5V; 0...10V; 4...20mA; CANopen, SAE J1939 • Electrical connections: AMP Superseal 6P 282108-1; cable output 18 AWG 1.65mm OD • Resolution and speed of rotation: 12 bit (analog output); 14 bit (CANopen/SAE J1939 output); 120 rpm max. • Linearity: < ±0.5%FS • Working and coefficient temperature: -40°C ... +85°C (higher values on request); thermal drift < 50 ppm/°C -

Features • Measurement range: ±180° different values on request programmable in steps of ±15° (ONLY for analogue versions) • Supply voltage: +5Vdc (only for 0.5..4.5Vdc output); +9…+36Vdc (see output signal for right supply voltage) • Output signal : 0.5...4.5V Ratiometric (supply +5Vdc); 0.5...4.5V; 0...10V; 4...20mA; CANopen, SAE J1939 • Electrical connections: AMP Superseal 6P 282108-1; DEUTSCH 6P DT04-6P • Resolution and speed of rotation: 12 bit (analog output); 14 bit (CANopen/SAE J1939 output); 120 rpm max. • Linearity: < ± 0.5% FS • Working and coefficient temperature: -40°C ... +85°C (higher values on request); thermal drift < 50 ppm/°C

Features • Measurement range: ±180° different values on request programmable in steps of ±15° (ONLY for analogue versions) • Supply voltage: +5Vdc (only for 0.5..4.5Vdc output); +9…+36Vdc (see output signal for right supply voltage) • Output signal : 0.5...4.5V Ratiometric (supply +5Vdc); 0.5...4.5V; 0...10V; 4...20mA; CANopen, SAE J1939 • Electrical connections: AMP Superseal 6P 282108-1; DEUTSCH 6P DT04-6P • Resolution and speed of rotation: 12 bit (analog output); 14 bit (CANopen/SAE J1939 output); 120 rpm max. • Linearity: < ± 0.5% FS • Working and coefficient temperature: -40°C ... +85°C (higher values on request); thermal drift < 50 ppm/°C -

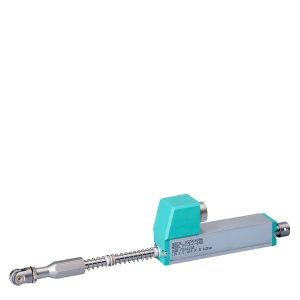

Features • The transducer has been improved in order to guarantee greater reliability under all conditions • A sturdier structure makes the LT series even stronger for applications with heavy vibration • Installation is made simpler by the absence of electrical signal variation in output, outside the Theoretical Electrical Stroke • The new grooves provide an excellent alternative to the usual system of fastening with brackets • Ideal for applications on plastic injection presses, vertical presses, and on many other processing machines

Features • The transducer has been improved in order to guarantee greater reliability under all conditions • A sturdier structure makes the LT series even stronger for applications with heavy vibration • Installation is made simpler by the absence of electrical signal variation in output, outside the Theoretical Electrical Stroke • The new grooves provide an excellent alternative to the usual system of fastening with brackets • Ideal for applications on plastic injection presses, vertical presses, and on many other processing machines -

Main Characteristics • Absolute transducer • Strokes from 50 to 4000mm (RK-4-_ _ _ _ -N/E/R) • Direct analog output (RK-4-_ _ _ _ -N/K/E) • Reverse analog output (RK-4-_ _ _ _ -R) • Operating temperature: -30...+90°C • Resistance to vibration (DIN IEC68T2/6 20g) • Power supply 18Vdc...30Vdc • Optional 12Vdc power supply (RK-4-_ _ _ _ -K)

Main Characteristics • Absolute transducer • Strokes from 50 to 4000mm (RK-4-_ _ _ _ -N/E/R) • Direct analog output (RK-4-_ _ _ _ -N/K/E) • Reverse analog output (RK-4-_ _ _ _ -R) • Operating temperature: -30...+90°C • Resistance to vibration (DIN IEC68T2/6 20g) • Power supply 18Vdc...30Vdc • Optional 12Vdc power supply (RK-4-_ _ _ _ -K) -

Main Characteristics • Absolute transducer • Strokes from 50 to 4000mm (RK-2-_ _ _ _ -N/E/S) • Digital output RS422 Start/Stop (RK-2-_ _ _ _ -S) • Direct analog output (RK-2-_ _ _ _ -N/K/E) • Operating temperature: -30...+90°C • Resistance to vibration (DIN IEC68T2/6 20g) • Power supply 18Vdc...30Vdc • Optional 12Vdc power supply (RK-2-_ _ _ _ -K) • The digital version (RK-2-_ _ _ _ -S) allows the remote connection (max. 50 m) of optional electronics for use of advanced analog (EKA)

Main Characteristics • Absolute transducer • Strokes from 50 to 4000mm (RK-2-_ _ _ _ -N/E/S) • Digital output RS422 Start/Stop (RK-2-_ _ _ _ -S) • Direct analog output (RK-2-_ _ _ _ -N/K/E) • Operating temperature: -30...+90°C • Resistance to vibration (DIN IEC68T2/6 20g) • Power supply 18Vdc...30Vdc • Optional 12Vdc power supply (RK-2-_ _ _ _ -K) • The digital version (RK-2-_ _ _ _ -S) allows the remote connection (max. 50 m) of optional electronics for use of advanced analog (EKA) -

Main Characteristics • Optimized mechanical structure • Strokes from 50 to 4000 mm • Wide range of connectors for the electrical connection • Rod, nipple, exagonal flange AISI 316 • Power supply 10....32 Vdc • Resistance to vibration (DIN IEC68T2/6 15g) • Protection IP67 • Work temperature: -30°…+90°C • Synchronous Serial Interface direct to controllers • Output data resolution available from 0.5 to 40μm • Data format: binary or Gray code; incremental/decremental • Electromagnetic compatibility EMC 2014/30/EU • Compliant to the directive RoHS 2011/65/EU

Main Characteristics • Optimized mechanical structure • Strokes from 50 to 4000 mm • Wide range of connectors for the electrical connection • Rod, nipple, exagonal flange AISI 316 • Power supply 10....32 Vdc • Resistance to vibration (DIN IEC68T2/6 15g) • Protection IP67 • Work temperature: -30°…+90°C • Synchronous Serial Interface direct to controllers • Output data resolution available from 0.5 to 40μm • Data format: binary or Gray code; incremental/decremental • Electromagnetic compatibility EMC 2014/30/EU • Compliant to the directive RoHS 2011/65/EU -

Main Characteristics • Optimized mechanical structure • Strokes from 50 to 2500 mm • Wide range of connectors for the electrical connection • Rod, nipple, exagonal flange AISI 316 • Power supply 10....32 Vdc • Resistance to vibration (DIN IEC68T2/6 12g) • Protection IP67 • Work temperature: -30°…+90°C • Synchronous Serial Interface direct to controllers • Output data resolution available from 20 to 40μm • Data format: binary or Gray code; incremental/decremental • Electromagnetic compatibility EMC 2014/30/EU • Compliant to the directive RoHS 2011/65/EU

Main Characteristics • Optimized mechanical structure • Strokes from 50 to 2500 mm • Wide range of connectors for the electrical connection • Rod, nipple, exagonal flange AISI 316 • Power supply 10....32 Vdc • Resistance to vibration (DIN IEC68T2/6 12g) • Protection IP67 • Work temperature: -30°…+90°C • Synchronous Serial Interface direct to controllers • Output data resolution available from 20 to 40μm • Data format: binary or Gray code; incremental/decremental • Electromagnetic compatibility EMC 2014/30/EU • Compliant to the directive RoHS 2011/65/EU