-

Principal Characteristics • The side connection creates a through-rod structure with double rod support, guaranteeing greater overall strength of the transducer. • The return spring automatically returns the rod to zero position, making the transducer suitable for comparator applications. • The tip with stainless steel ball is suitable for applications where the object to be measured is not subject to shifts transverse to the transducer axle. • Ideal for checking the flatness or thickness of panels of various materials. Can also be used for valves or mechanical parts when the rod cannot be attached to the moving object.

Principal Characteristics • The side connection creates a through-rod structure with double rod support, guaranteeing greater overall strength of the transducer. • The return spring automatically returns the rod to zero position, making the transducer suitable for comparator applications. • The tip with stainless steel ball is suitable for applications where the object to be measured is not subject to shifts transverse to the transducer axle. • Ideal for checking the flatness or thickness of panels of various materials. Can also be used for valves or mechanical parts when the rod cannot be attached to the moving object. -

Principal Characteristics • The side connection creates a through-rod structure with double rod support, guaranteeing greater overall strength of the transducer. • The return spring automatically returns the rod to zero position, making the transducer suitable for comparator applications. • The tip with roller bearing is suitable for applications where the object to be measured may be subject to shifts transverse to the transducer axle (shaft is prevented from rotating). • Ideal for checking the flatness or thickness of panels of various materials. Can also be used for valves or mechanical parts when the rod cannot be attached to the moving object

Principal Characteristics • The side connection creates a through-rod structure with double rod support, guaranteeing greater overall strength of the transducer. • The return spring automatically returns the rod to zero position, making the transducer suitable for comparator applications. • The tip with roller bearing is suitable for applications where the object to be measured may be subject to shifts transverse to the transducer axle (shaft is prevented from rotating). • Ideal for checking the flatness or thickness of panels of various materials. Can also be used for valves or mechanical parts when the rod cannot be attached to the moving object -

Principal Characteristics • The 1/2” cylindrical housing, plus the option of all fastening systems (brackets, joints or flange), makes the PZ12 series highly versatile for a wide range of applications. • The optimized mechanical structure makes the product suitable for developing various special executions (contact Gefran customer service for details). • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • Ideal for wood and glass working and finishing machines and for car test benches.

Principal Characteristics • The 1/2” cylindrical housing, plus the option of all fastening systems (brackets, joints or flange), makes the PZ12 series highly versatile for a wide range of applications. • The optimized mechanical structure makes the product suitable for developing various special executions (contact Gefran customer service for details). • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • Ideal for wood and glass working and finishing machines and for car test benches. -

Principal Characteristics • The 3/4” cylindrical housing, plus the option of all fastening systems (brackets, joints or flange), makes the PZ34 series highly versatile for a wide range of applications. • The optimized mechanical structure makes the product suitable for developing various special executions (contact Gefran customer service for details). • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • Ideal for wood and glass working and finishing machines and for car test benches.

Principal Characteristics • The 3/4” cylindrical housing, plus the option of all fastening systems (brackets, joints or flange), makes the PZ34 series highly versatile for a wide range of applications. • The optimized mechanical structure makes the product suitable for developing various special executions (contact Gefran customer service for details). • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • Ideal for wood and glass working and finishing machines and for car test benches. -

Features • This transducer is designed to guarantee a high protection level (IP67) in applications under harsh conditions and outdoors, where it may be necessary to work in the direct presence of dust, dirt, or liquids (not in prolonged immersion) • Its high protection level and very small size make the PZ67-A unique in terms of reliability and flexible installation • It is ideal for glass cutting and washing machines or for honers and sanders if there is direct exposure to liquids or even just steam • Indicated for test and bench equipment, especially if outdoors

Features • This transducer is designed to guarantee a high protection level (IP67) in applications under harsh conditions and outdoors, where it may be necessary to work in the direct presence of dust, dirt, or liquids (not in prolonged immersion) • Its high protection level and very small size make the PZ67-A unique in terms of reliability and flexible installation • It is ideal for glass cutting and washing machines or for honers and sanders if there is direct exposure to liquids or even just steam • Indicated for test and bench equipment, especially if outdoors -

Features • This transducer is designed to guarantee a high protection level (IP67) in applications under harsh conditions and outdoors, where it may be necessary to work in the direct presence of dust, dirt, or liquids (not in prolonged immersion) • Its high protection level and very small size make the PZ67-S unique in terms of reliability and flexible installation • It is ideal for glass cutting and washing machines or for honers and sanders if there is direct exposure to liquids or even just steam • Indicated for test and bench equipment, especially if outdoors

Features • This transducer is designed to guarantee a high protection level (IP67) in applications under harsh conditions and outdoors, where it may be necessary to work in the direct presence of dust, dirt, or liquids (not in prolonged immersion) • Its high protection level and very small size make the PZ67-S unique in terms of reliability and flexible installation • It is ideal for glass cutting and washing machines or for honers and sanders if there is direct exposure to liquids or even just steam • Indicated for test and bench equipment, especially if outdoors -

Features • Direct measurement of surface strain • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • Without amplifier (passive)

Features • Direct measurement of surface strain • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • Without amplifier (passive) -

Features • Complete system for the strain-measurement on one tie bar • Direct display of strain values in µe, kN or t • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 1- channel digital monitor DU1D • Battery operation possible (optional) / not rechargeable • Very compact and easy to use system

Features • Complete system for the strain-measurement on one tie bar • Direct display of strain values in µe, kN or t • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 1- channel digital monitor DU1D • Battery operation possible (optional) / not rechargeable • Very compact and easy to use system -

Features • Complete system for the simultaneous strain-measurement on up to four tie bars • Direct display of strain values in µe, kN or t • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 4- channel digital monitor DU4D • USB connection for tie bar adjustment software (optional) • Very compact and easy to use system

Features • Complete system for the simultaneous strain-measurement on up to four tie bars • Direct display of strain values in µe, kN or t • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 4- channel digital monitor DU4D • USB connection for tie bar adjustment software (optional) • Very compact and easy to use system -

Features • Complete system for the simultaneous strain-measurement on up to four tie bars • Direct display of strain values in µe, kN or t (via our Inspectmate software) • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 4- channel digital monitor-box DU-4USB • USB connection for tie bar adjustment software and power supply • Very compact and easy to use system

Features • Complete system for the simultaneous strain-measurement on up to four tie bars • Direct display of strain values in µe, kN or t (via our Inspectmate software) • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 4- channel digital monitor-box DU-4USB • USB connection for tie bar adjustment software and power supply • Very compact and easy to use system -

Features • Measure strain in any direction in seconds • Smallest press-on sensor with magnet mounting • Direct surface strain reading like bonded strain gages, high linearity on tension and compression • Quick and easy mounting on magnetic structures • Calibrated sensor (K=2.00) for dynamic applications • Ideal for checking FEM calculations and for stress analysis on flat steel structures • Without amplifier (passiv) • External amplifier recommended (e.g. MBA100; VDA, Monitor DU-1D

Features • Measure strain in any direction in seconds • Smallest press-on sensor with magnet mounting • Direct surface strain reading like bonded strain gages, high linearity on tension and compression • Quick and easy mounting on magnetic structures • Calibrated sensor (K=2.00) for dynamic applications • Ideal for checking FEM calculations and for stress analysis on flat steel structures • Without amplifier (passiv) • External amplifier recommended (e.g. MBA100; VDA, Monitor DU-1D -

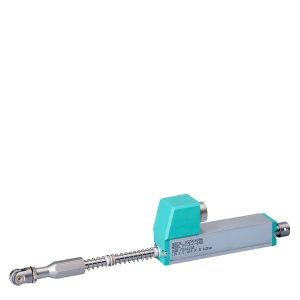

Main Characteristics • Absolute transducer • Strokes from 50 to 4000mm (RK-2-_ _ _ _ -N/E/S) • Digital output RS422 Start/Stop (RK-2-_ _ _ _ -S) • Direct analog output (RK-2-_ _ _ _ -N/K/E) • Operating temperature: -30...+90°C • Resistance to vibration (DIN IEC68T2/6 20g) • Power supply 18Vdc...30Vdc • Optional 12Vdc power supply (RK-2-_ _ _ _ -K) • The digital version (RK-2-_ _ _ _ -S) allows the remote connection (max. 50 m) of optional electronics for use of advanced analog (EKA)

Main Characteristics • Absolute transducer • Strokes from 50 to 4000mm (RK-2-_ _ _ _ -N/E/S) • Digital output RS422 Start/Stop (RK-2-_ _ _ _ -S) • Direct analog output (RK-2-_ _ _ _ -N/K/E) • Operating temperature: -30...+90°C • Resistance to vibration (DIN IEC68T2/6 20g) • Power supply 18Vdc...30Vdc • Optional 12Vdc power supply (RK-2-_ _ _ _ -K) • The digital version (RK-2-_ _ _ _ -S) allows the remote connection (max. 50 m) of optional electronics for use of advanced analog (EKA) -

Main Characteristics • Absolute transducer • Strokes from 50 to 4000mm (RK-4-_ _ _ _ -N/E/R) • Direct analog output (RK-4-_ _ _ _ -N/K/E) • Reverse analog output (RK-4-_ _ _ _ -R) • Operating temperature: -30...+90°C • Resistance to vibration (DIN IEC68T2/6 20g) • Power supply 18Vdc...30Vdc • Optional 12Vdc power supply (RK-4-_ _ _ _ -K)

Main Characteristics • Absolute transducer • Strokes from 50 to 4000mm (RK-4-_ _ _ _ -N/E/R) • Direct analog output (RK-4-_ _ _ _ -N/K/E) • Reverse analog output (RK-4-_ _ _ _ -R) • Operating temperature: -30...+90°C • Resistance to vibration (DIN IEC68T2/6 20g) • Power supply 18Vdc...30Vdc • Optional 12Vdc power supply (RK-4-_ _ _ _ -K) -

S55 .. S300 Series Family

S55 .. S300 Series Family- S55-PP 2000 - 6000 l/h

- S110-PP 2000 - 14000 l/h

- S150-PP 2000 - 18000 l/h

- S220-PP 10 - 24 m3/h

- S300-PP 10 - 32 m3/h

-

Features • Small press-on sensor with one-hole mounting • Direct measurement of surface strain • Without amplifier (passiv) • High accuracy and linearity in tension and pressure (like bonded strain gauges) • For dynamic applications • Used on presses, injection moulding and die-casting machines • Quick and easy mounting • Protected against overload • Optional accessories: - Signal amplifier VDA - Monitor DU-1D

Features • Small press-on sensor with one-hole mounting • Direct measurement of surface strain • Without amplifier (passiv) • High accuracy and linearity in tension and pressure (like bonded strain gauges) • For dynamic applications • Used on presses, injection moulding and die-casting machines • Quick and easy mounting • Protected against overload • Optional accessories: - Signal amplifier VDA - Monitor DU-1D -

Features • Direct measurement of surface strain • With high grade variable digital amplifier • Amplifies the signal on the spot, avoiding EMC problems • High accuracy and linearity in tension and pressure (like bonded strain gauges) • For dynamic applications • Used on presses, injection moulding and die-casting machines • Quick and easy mounting • Protected against overload

Features • Direct measurement of surface strain • With high grade variable digital amplifier • Amplifies the signal on the spot, avoiding EMC problems • High accuracy and linearity in tension and pressure (like bonded strain gauges) • For dynamic applications • Used on presses, injection moulding and die-casting machines • Quick and easy mounting • Protected against overload -

SHX Series Family

SHX Series Family- SHX60-SS 2000 - 6200 l/h

- SHX140-SS 2000 - 14000 l/h

- SHX250-SS 2000 - 25000 l/h

- SHX300-SS 2 - 30 m3/h

- SHX500-SS 2 - 50 m3/h

-

Features • 2-channel controller (Basic type: 1-channel controller) • Independent 2-loop / Internal Cascade / 2-input operation control • High accuracy ± (0.1% FS + 1 digit) • High Sampling Cycle 0.1 sec. • High resolution 1/ 1000 °C display achieved *Only for R.T.D. input (scale: 0.000~30.000 °C) • Auto-Tuning PID / Expert PID / Self-Tuning PID • Multi-Setting of 10 Set Values • Independent Universal-Input • User Friendly Operation (Menu Driven: 4 Lines LCD Display) • Easy Setting & Maintenance via Infrared COM port on the front panel • Interface RS-232C/RS-485 (MODBUS / Shimaden) • The front dust/splash-proof IP66 • Universal Power Supply (100~240V AC ±10%) • Sensor power supply

Features • 2-channel controller (Basic type: 1-channel controller) • Independent 2-loop / Internal Cascade / 2-input operation control • High accuracy ± (0.1% FS + 1 digit) • High Sampling Cycle 0.1 sec. • High resolution 1/ 1000 °C display achieved *Only for R.T.D. input (scale: 0.000~30.000 °C) • Auto-Tuning PID / Expert PID / Self-Tuning PID • Multi-Setting of 10 Set Values • Independent Universal-Input • User Friendly Operation (Menu Driven: 4 Lines LCD Display) • Easy Setting & Maintenance via Infrared COM port on the front panel • Interface RS-232C/RS-485 (MODBUS / Shimaden) • The front dust/splash-proof IP66 • Universal Power Supply (100~240V AC ±10%) • Sensor power supply -

Features • Multi-input and multi-range performance • Small instrument depths (62mm - 65mm) save space, thus securing a larger installation area. • SV setting: 3 points • PID Value: 3 types • 2-output heating and cooling control available (optional) • Total 32 steps Program available (optional) (1-4 pattern, 32-8 step) • RS-485 Interface available (optional) (Master/slave function, Modbus/Shimaden Protocol) • Heater break/heater loop alarm (optional) • A wide selection of additional functions (optional) is available to suit various needs. • Possible to switch off SV/PV value by key operation • Parameter mask (non-display) / lock (key lock) function

Features • Multi-input and multi-range performance • Small instrument depths (62mm - 65mm) save space, thus securing a larger installation area. • SV setting: 3 points • PID Value: 3 types • 2-output heating and cooling control available (optional) • Total 32 steps Program available (optional) (1-4 pattern, 32-8 step) • RS-485 Interface available (optional) (Master/slave function, Modbus/Shimaden Protocol) • Heater break/heater loop alarm (optional) • A wide selection of additional functions (optional) is available to suit various needs. • Possible to switch off SV/PV value by key operation • Parameter mask (non-display) / lock (key lock) function -

Features • Multi-input and multi-range performance • Small instrument depths (62mm - 65mm) save space, thus securing a larger installation area. • SV setting: 3 points • PID Value: 3 types • 2-output heating and cooling control available (optional) • Total 32 steps Program available (optional) (1-4 pattern, 32-8 step) • RS-485 Interface available (optional) (Master/slave function, Modbus/Shimaden Protocol) • Heater break/heater loop alarm (optional) • A wide selection of additional functions (optional) is available to suit various needs. • Possible to switch off SV/PV value by key operation • Parameter mask (non-display) / lock (key lock) function

Features • Multi-input and multi-range performance • Small instrument depths (62mm - 65mm) save space, thus securing a larger installation area. • SV setting: 3 points • PID Value: 3 types • 2-output heating and cooling control available (optional) • Total 32 steps Program available (optional) (1-4 pattern, 32-8 step) • RS-485 Interface available (optional) (Master/slave function, Modbus/Shimaden Protocol) • Heater break/heater loop alarm (optional) • A wide selection of additional functions (optional) is available to suit various needs. • Possible to switch off SV/PV value by key operation • Parameter mask (non-display) / lock (key lock) function -

Ceramic Block Our ceramic terminal blocks fit into all of our general purpose terminal heads. These are common and can be used for both RTD and thermocouple assemblies. They are field configurable for 2, 3, 4 or 6 wire configurations. The ceramic base protects against elevated temperature and the tin coated screw design terminals make for an easy termination.

Ceramic Block Our ceramic terminal blocks fit into all of our general purpose terminal heads. These are common and can be used for both RTD and thermocouple assemblies. They are field configurable for 2, 3, 4 or 6 wire configurations. The ceramic base protects against elevated temperature and the tin coated screw design terminals make for an easy termination.