- MX40-PP 2000 - 4200 l/h

- MX40-PVDF 2000 - 4200 l/h

- MX60-PP 2000 - 6000 l/h

- MX60-PVDF 2000 - 6000 l/h

- MX61-PP 2000 - 6000 l/h

- MX61-PVDF 2000 - 6000 l/h

- MX62-PP 2000 - 6000 l/h

- MX62-PVDF 2000 - 6000 l/h

- MX90-PP 2000 - 8200 l/h

- MX90-PVDF 2000 - 8200 l/h

- MX91-PP 2000 - 8200 l/h

- MX91-PVDF 2000 - 8200 l/h

- MX120-PP 2000 - 12000 l/h

- MX120-PVDF 2000 - 12000 l/h

-

MX40 .. MX120 Series Family

MX40 .. MX120 Series Family -

MXH Series Family

MXH Series Family- MXH150-PP 6000 - 15000 l/h

- MXH150-PVDF 6000 - 15000 l/h

- MXH220-PP 6000 - 22000 l/h

- MXH220-PVDF 6000 - 22000 l/h

- MXH300-PP 6000 - 30000 l/h

- MXH300-PVDF 6000 - 30000 l/h

- MXH380-PP 6000 - 38000 l/h

- MXH380-PVDF 6000 - 38000 l/h

- MXH450-PVDF 6000 - 45000 l/h

-

Principal Characteristics • The transducer’s compactness makes it suitable for installation in small spaces and for detecting small shifts. • The joint with up-take of slack and M4 threading provides greater tolerances in movement. • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • Ideal for small mechanical devices, valves, and test tools and benches.

Principal Characteristics • The transducer’s compactness makes it suitable for installation in small spaces and for detecting small shifts. • The joint with up-take of slack and M4 threading provides greater tolerances in movement. • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • Ideal for small mechanical devices, valves, and test tools and benches. -

Principal Characteristics • The transducer is designed to satisfy extreme applicative demands in terms of mechanical strength. • The 10 mm diameter rod, large steel joints, and reinforced structure make this series mechanically ideal for Metal working, woodworking, and ceramics. • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • The structure based on self-aligning and weight-bearing ball joints permits assembly with free movement of the transducer axle

Principal Characteristics • The transducer is designed to satisfy extreme applicative demands in terms of mechanical strength. • The 10 mm diameter rod, large steel joints, and reinforced structure make this series mechanically ideal for Metal working, woodworking, and ceramics. • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • The structure based on self-aligning and weight-bearing ball joints permits assembly with free movement of the transducer axle -

Applicative Characteristics • The PC67 displacement transducer was developed to guarantee a high protection level (IP67) in applications under harsh conditions and outdoors, where it may be necessary to work in the presence of dust, dirt, or liquids (not in prolonged immersion). • The robust structure of the PC series has been improved thanks to a sealing system (patent pending) that makes it extremely reliable. • Ideal for mobile hydraulic applications, on agricultural machines, earth-moving equipment and utility vehicles

Applicative Characteristics • The PC67 displacement transducer was developed to guarantee a high protection level (IP67) in applications under harsh conditions and outdoors, where it may be necessary to work in the presence of dust, dirt, or liquids (not in prolonged immersion). • The robust structure of the PC series has been improved thanks to a sealing system (patent pending) that makes it extremely reliable. • Ideal for mobile hydraulic applications, on agricultural machines, earth-moving equipment and utility vehicles -

Features • Interface module integrated in the connector • Standard output 0...10Vdc (PCIR 101) • Standard output 4...20mA(PCIR 102) • High linearity • Adjustable Zero and Span • Low zero and span thermal drift • 4 pole female DIN43650 connector for LTM and PKM potentiometer • DIN 43650 4-pin female connector for direct connection to LTM and PKM potentiometers (the DIN 43650 connector in the PCM series is smaller and cannot be connected directly)

Features • Interface module integrated in the connector • Standard output 0...10Vdc (PCIR 101) • Standard output 4...20mA(PCIR 102) • High linearity • Adjustable Zero and Span • Low zero and span thermal drift • 4 pole female DIN43650 connector for LTM and PKM potentiometer • DIN 43650 4-pin female connector for direct connection to LTM and PKM potentiometers (the DIN 43650 connector in the PCM series is smaller and cannot be connected directly) -

Features

Features- Silicon chips on differential pressure module of MEMS integration technology

- Offset function / UI software

- Low-pressure monitoring, high pressure resistance

- RS-485 communication interface(Optional), Modbus RTU protocol

- Physical unit switch(User Interface):mbar / Pa / hPa / kPa / mmH2O / mmWS / inH2O / mmHg

- Square root function

-

Features • The transducer has been improved in order to guarantee greater reliability under all conditions • Mechanical linkage using joint with take up of play, M5 thread • Installation is made simpler by the absence of electrical signal variation in output, outside the Theoretical Electrical Stroke • The new grooves provide an excellent alternative to the usual system of fastening with brackets • Ideal for applications on plastic injection presses, vertical presses, and on many other processing machines • Grade of protection IP40

Features • The transducer has been improved in order to guarantee greater reliability under all conditions • Mechanical linkage using joint with take up of play, M5 thread • Installation is made simpler by the absence of electrical signal variation in output, outside the Theoretical Electrical Stroke • The new grooves provide an excellent alternative to the usual system of fastening with brackets • Ideal for applications on plastic injection presses, vertical presses, and on many other processing machines • Grade of protection IP40 -

Principal Characteristics • The PMA-12 transducer, a development of the PME series, is designed for installation with self-aligning joints. • The IP67 protection level makes the PMA-12 highly suitable for humid and wet environments and in temporary immersion (CEI EN 60529). • Available only with cable output. • Ideal for applications on metalworking and ceramics machines, as well as on earth-moving machines and utility vehicles. Recommended in all cases where the angle of the drive axle changes constantly.

Principal Characteristics • The PMA-12 transducer, a development of the PME series, is designed for installation with self-aligning joints. • The IP67 protection level makes the PMA-12 highly suitable for humid and wet environments and in temporary immersion (CEI EN 60529). • Available only with cable output. • Ideal for applications on metalworking and ceramics machines, as well as on earth-moving machines and utility vehicles. Recommended in all cases where the angle of the drive axle changes constantly. -

Features

Features- Silicon chips on differential pressure module of MEMS integration technology

- Offset function / UI software

- Low-pressure monitoring, high pressure resistance

- RS-485 communication interface (Optional), Modbus RTU protocol

- Physical unit switch (User Interface):mbar / Pa / hPa / kPa / mmH2O / mmWS / inH2O / mmHg

- Square root function

-

Features • Rectilinear displacement transducer without drag shaft, completely water-tight (IP67), designed to work in humid environments (CEI EN 60529) • The PME series has an external magnetic actuator linked to an internal measurement cursor • The magnetic cursor replaces the drag shaft used in traditional displacement transducers, making the instrument even more compact • Installation is made simpler because there is no variation in the electrical output signal outside the Theoretical Electrical Stroke • The instrument can be used in compressed air applications with max. working pressure of 20 bar.

Features • Rectilinear displacement transducer without drag shaft, completely water-tight (IP67), designed to work in humid environments (CEI EN 60529) • The PME series has an external magnetic actuator linked to an internal measurement cursor • The magnetic cursor replaces the drag shaft used in traditional displacement transducers, making the instrument even more compact • Installation is made simpler because there is no variation in the electrical output signal outside the Theoretical Electrical Stroke • The instrument can be used in compressed air applications with max. working pressure of 20 bar. -

Main Characteristics • The PMI-12 transducer is designed for use inside oil pressure cylinders, applications that demand high strength. • The AISI316 stainless steel body and elevated protection level permit installation in cylinders with pressures up to 250 bar (400 bar peak). • Available with internal flanges or external threads to guarantee mechanical compatibility with all principal cylinder types. • Patented

Main Characteristics • The PMI-12 transducer is designed for use inside oil pressure cylinders, applications that demand high strength. • The AISI316 stainless steel body and elevated protection level permit installation in cylinders with pressures up to 250 bar (400 bar peak). • Available with internal flanges or external threads to guarantee mechanical compatibility with all principal cylinder types. • Patented -

Applicative Characteristics • The PMI-SL transducer, an evolution of the PMI-12, is designed for all inside cylinder applications which require a smaller transducer. For this reason, the diameter has been reduced to 12.7 mm. • The PMI Slim offers the same robustness as the PMI-12: AISI 316 stainless steel body, IP67 protection level, and pressure resistance up to 250 bar (400 bar peak) • Available with flanged or threaded heads, to guarantee mechanical compatibility with all main cylinder types • Patented solution • Ideal for applications inside hydraulic cylinders, demanding simple solutions which guarantee measurement repeatability

Applicative Characteristics • The PMI-SL transducer, an evolution of the PMI-12, is designed for all inside cylinder applications which require a smaller transducer. For this reason, the diameter has been reduced to 12.7 mm. • The PMI Slim offers the same robustness as the PMI-12: AISI 316 stainless steel body, IP67 protection level, and pressure resistance up to 250 bar (400 bar peak) • Available with flanged or threaded heads, to guarantee mechanical compatibility with all main cylinder types • Patented solution • Ideal for applications inside hydraulic cylinders, demanding simple solutions which guarantee measurement repeatability -

Applicative Characteristics • The PMI-SLE transducer, is the amplified version of the PMI-SL, a product designed for all inside cylinder applications which require a smaller transducer (the rod diameter is only 12,7 mm). • The PMI Slim offers the same robustness: stainlessteel body, IP67 protection level, and pressure resistance up to 250 bar (400 bar peak) • Available with flanged or threaded heads, to guarantee mechanical compatibility with all main cylinder types • Patented solution • Ideal for applications inside hydraulic cylinders, demanding simple solutions which guarantee measurement repeatability.

Applicative Characteristics • The PMI-SLE transducer, is the amplified version of the PMI-SL, a product designed for all inside cylinder applications which require a smaller transducer (the rod diameter is only 12,7 mm). • The PMI Slim offers the same robustness: stainlessteel body, IP67 protection level, and pressure resistance up to 250 bar (400 bar peak) • Available with flanged or threaded heads, to guarantee mechanical compatibility with all main cylinder types • Patented solution • Ideal for applications inside hydraulic cylinders, demanding simple solutions which guarantee measurement repeatability. -

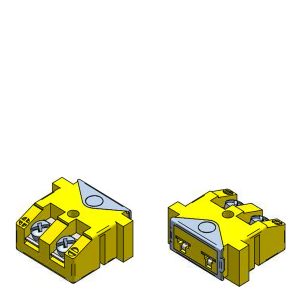

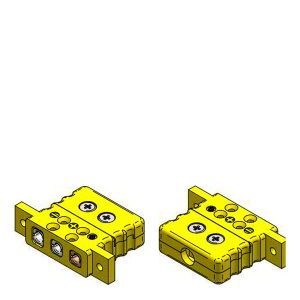

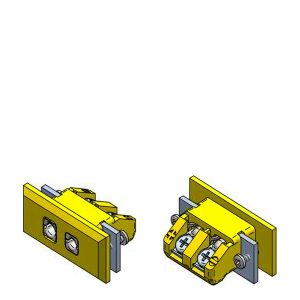

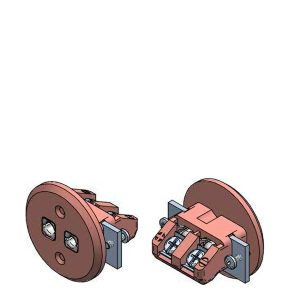

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins ensure proper connection • Easy wire connection through sandwich construction • Molded barriers prevent short circuit • Rugged one body design • Polarity indication on body • Stainless steel bracket and screws for rear panel mounting

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins ensure proper connection • Easy wire connection through sandwich construction • Molded barriers prevent short circuit • Rugged one body design • Polarity indication on body • Stainless steel bracket and screws for rear panel mounting -

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins ensure proper connection • Easy wire connection through sandwich construction • Molded barriers prevent short circuit • Rugged one body design • Polarity indication on body • Stainless steel bracket and screws for rear panel mounting

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins ensure proper connection • Easy wire connection through sandwich construction • Molded barriers prevent short circuit • Rugged one body design • Polarity indication on body • Stainless steel bracket and screws for rear panel mounting -

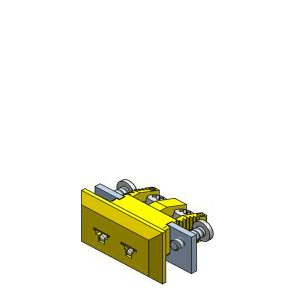

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins ensure proper connection • Easy wire connection through sandwich construction • Molded barriers prevent short circuit • Rugged one body design • Polarity indication on body • Stainless steel screws and brackets for front mounting

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins ensure proper connection • Easy wire connection through sandwich construction • Molded barriers prevent short circuit • Rugged one body design • Polarity indication on body • Stainless steel screws and brackets for front mounting -

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins ensure proper connection • Easy wire connection through sandwich construction • Molded barriers prevent short circuit • Rugged one body design • Polarity indication on body • Stainless steel bracket and screws for rear panel mounting

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins ensure proper connection • Easy wire connection through sandwich construction • Molded barriers prevent short circuit • Rugged one body design • Polarity indication on body • Stainless steel bracket and screws for rear panel mounting -

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts. • Polarized pins ensure proper connection • Easy wire connection through sandwich construction • Molded barriers prevent short circuit • Rugged one body design • Polarity indication on body • Stainless steel bracket and screws for rear panel mounting

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts. • Polarized pins ensure proper connection • Easy wire connection through sandwich construction • Molded barriers prevent short circuit • Rugged one body design • Polarity indication on body • Stainless steel bracket and screws for rear panel mounting -

Features • Sealed industrial version • Independent linearity up to ± 0,05% (standard ± 0,5%) • Working temperature: -55...+100°C • Repetibility 0,01% della C.E.T. • Life duration: >100x106 operations at 10 r.p.s. (within C.E.U.) • Infinite resolution • Electrical connection: 5-pole connector DIN 43322 • Grade of protection IP65 • Suitable for use in explosive environments with presence of gas (groups IIA, IIB, IIC) and combustible powders. Standards for simple device: ATEX CEI EN 50020 2003 - paragraph 5.4 a

Features • Sealed industrial version • Independent linearity up to ± 0,05% (standard ± 0,5%) • Working temperature: -55...+100°C • Repetibility 0,01% della C.E.T. • Life duration: >100x106 operations at 10 r.p.s. (within C.E.U.) • Infinite resolution • Electrical connection: 5-pole connector DIN 43322 • Grade of protection IP65 • Suitable for use in explosive environments with presence of gas (groups IIA, IIB, IIC) and combustible powders. Standards for simple device: ATEX CEI EN 50020 2003 - paragraph 5.4 a -

Priming chambers add a self-priming feature to a standard horizontal pump. A centrifugal pump by its principle is not self-priming, because of its limited ability to transport air. The priming chamber is initially filled with solution. The priming time depends on length/diameter of suction pipe. After the initial filling of the chamber, next time, the pump will automatically reprime. [ Click here for more details ]

Priming chambers add a self-priming feature to a standard horizontal pump. A centrifugal pump by its principle is not self-priming, because of its limited ability to transport air. The priming chamber is initially filled with solution. The priming time depends on length/diameter of suction pipe. After the initial filling of the chamber, next time, the pump will automatically reprime. [ Click here for more details ] -

Features • Models 09, 11, 20 • Servo mounting • Independent linearity up to ± 0,05% (standard ± 0,5%) • Repetibility 0,01% C.E.T. • Rotation speed ≤ 600 r.p.m. (within C.E.U.) • Life duration: >100x106 operations at 10 r.p.s. • Infinite resolution • Electrical terminals: turrets • Grade of protection IP40 • Suitable for use in explosive environments with presence of gas (groups IIA, IIB, IIC) and combustible powders. Standards for simple device: ATEX CEI EN 50020 2003 - paragraph 5.4 a

Features • Models 09, 11, 20 • Servo mounting • Independent linearity up to ± 0,05% (standard ± 0,5%) • Repetibility 0,01% C.E.T. • Rotation speed ≤ 600 r.p.m. (within C.E.U.) • Life duration: >100x106 operations at 10 r.p.s. • Infinite resolution • Electrical terminals: turrets • Grade of protection IP40 • Suitable for use in explosive environments with presence of gas (groups IIA, IIB, IIC) and combustible powders. Standards for simple device: ATEX CEI EN 50020 2003 - paragraph 5.4 a -

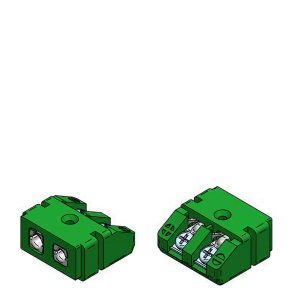

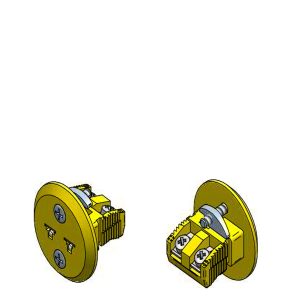

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins ensure proper connection • Molded barriers prevent short circuit • Polarity indication on the body • Rugged one body design • Stainless steel screws and bracket for rear mounting

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins ensure proper connection • Molded barriers prevent short circuit • Polarity indication on the body • Rugged one body design • Stainless steel screws and bracket for rear mounting -

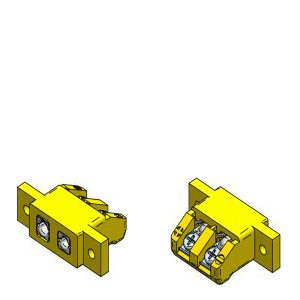

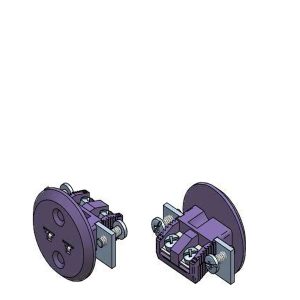

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins ensure proper connection • Easy wire connection through sandwich construction • Molded barriers prevent short circuit • Rugged one body design • Polarity indication on body • Stainless steel screws and brackets for front mounting

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins ensure proper connection • Easy wire connection through sandwich construction • Molded barriers prevent short circuit • Rugged one body design • Polarity indication on body • Stainless steel screws and brackets for front mounting -

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins ensure proper connection • Easy wire connection through sandwich construction • Molded barriers prevent short circuit • Rugged one body design • Polarity indication on body • Stainless steel screws and bracket for rear mounting

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins ensure proper connection • Easy wire connection through sandwich construction • Molded barriers prevent short circuit • Rugged one body design • Polarity indication on body • Stainless steel screws and bracket for rear mounting -

Principal Characteristics • The transducer’s compactness makes it suitable for installation in small spaces and for detecting small shifts. • The side connection creates a through-rod structure with double rod support, guaranteeing greater overall strength of the transducer. • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • Ideal for small mechanical devices, valves, and test tools and benches.

Principal Characteristics • The transducer’s compactness makes it suitable for installation in small spaces and for detecting small shifts. • The side connection creates a through-rod structure with double rod support, guaranteeing greater overall strength of the transducer. • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • Ideal for small mechanical devices, valves, and test tools and benches. -

Principal Characteristics • The side connection creates a through-rod structure with double rod support, guaranteeing greater overall strength of the transducer. • The return spring automatically returns the rod to zero position, making the transducer suitable for comparator applications. • The tip with stainless steel ball is suitable for applications where the object to be measured is not subject to shifts transverse to the transducer axle. • Ideal for checking the flatness or thickness of panels of various materials. Can also be used for valves or mechanical parts when the rod cannot be attached to the moving object.

Principal Characteristics • The side connection creates a through-rod structure with double rod support, guaranteeing greater overall strength of the transducer. • The return spring automatically returns the rod to zero position, making the transducer suitable for comparator applications. • The tip with stainless steel ball is suitable for applications where the object to be measured is not subject to shifts transverse to the transducer axle. • Ideal for checking the flatness or thickness of panels of various materials. Can also be used for valves or mechanical parts when the rod cannot be attached to the moving object. -

Principal Characteristics • The side connection creates a through-rod structure with double rod support, guaranteeing greater overall strength of the transducer. • The return spring automatically returns the rod to zero position, making the transducer suitable for comparator applications. • The tip with roller bearing is suitable for applications where the object to be measured may be subject to shifts transverse to the transducer axle (shaft is prevented from rotating). • Ideal for checking the flatness or thickness of panels of various materials. Can also be used for valves or mechanical parts when the rod cannot be attached to the moving object

Principal Characteristics • The side connection creates a through-rod structure with double rod support, guaranteeing greater overall strength of the transducer. • The return spring automatically returns the rod to zero position, making the transducer suitable for comparator applications. • The tip with roller bearing is suitable for applications where the object to be measured may be subject to shifts transverse to the transducer axle (shaft is prevented from rotating). • Ideal for checking the flatness or thickness of panels of various materials. Can also be used for valves or mechanical parts when the rod cannot be attached to the moving object -

Principal Characteristics • The 1/2” cylindrical housing, plus the option of all fastening systems (brackets, joints or flange), makes the PZ12 series highly versatile for a wide range of applications. • The optimized mechanical structure makes the product suitable for developing various special executions (contact Gefran customer service for details). • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • Ideal for wood and glass working and finishing machines and for car test benches.

Principal Characteristics • The 1/2” cylindrical housing, plus the option of all fastening systems (brackets, joints or flange), makes the PZ12 series highly versatile for a wide range of applications. • The optimized mechanical structure makes the product suitable for developing various special executions (contact Gefran customer service for details). • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • Ideal for wood and glass working and finishing machines and for car test benches. -

Principal Characteristics • The 3/4” cylindrical housing, plus the option of all fastening systems (brackets, joints or flange), makes the PZ34 series highly versatile for a wide range of applications. • The optimized mechanical structure makes the product suitable for developing various special executions (contact Gefran customer service for details). • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • Ideal for wood and glass working and finishing machines and for car test benches.

Principal Characteristics • The 3/4” cylindrical housing, plus the option of all fastening systems (brackets, joints or flange), makes the PZ34 series highly versatile for a wide range of applications. • The optimized mechanical structure makes the product suitable for developing various special executions (contact Gefran customer service for details). • Installation is simplified by the lack of electrical signal variation at output outside theoretical electrical stroke. • Ideal for wood and glass working and finishing machines and for car test benches. -

Features • This transducer is designed to guarantee a high protection level (IP67) in applications under harsh conditions and outdoors, where it may be necessary to work in the direct presence of dust, dirt, or liquids (not in prolonged immersion) • Its high protection level and very small size make the PZ67-A unique in terms of reliability and flexible installation • It is ideal for glass cutting and washing machines or for honers and sanders if there is direct exposure to liquids or even just steam • Indicated for test and bench equipment, especially if outdoors

Features • This transducer is designed to guarantee a high protection level (IP67) in applications under harsh conditions and outdoors, where it may be necessary to work in the direct presence of dust, dirt, or liquids (not in prolonged immersion) • Its high protection level and very small size make the PZ67-A unique in terms of reliability and flexible installation • It is ideal for glass cutting and washing machines or for honers and sanders if there is direct exposure to liquids or even just steam • Indicated for test and bench equipment, especially if outdoors -

Features • This transducer is designed to guarantee a high protection level (IP67) in applications under harsh conditions and outdoors, where it may be necessary to work in the direct presence of dust, dirt, or liquids (not in prolonged immersion) • Its high protection level and very small size make the PZ67-S unique in terms of reliability and flexible installation • It is ideal for glass cutting and washing machines or for honers and sanders if there is direct exposure to liquids or even just steam • Indicated for test and bench equipment, especially if outdoors

Features • This transducer is designed to guarantee a high protection level (IP67) in applications under harsh conditions and outdoors, where it may be necessary to work in the direct presence of dust, dirt, or liquids (not in prolonged immersion) • Its high protection level and very small size make the PZ67-S unique in terms of reliability and flexible installation • It is ideal for glass cutting and washing machines or for honers and sanders if there is direct exposure to liquids or even just steam • Indicated for test and bench equipment, especially if outdoors -

Features • Direct measurement of surface strain • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • Without amplifier (passive)

Features • Direct measurement of surface strain • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • Without amplifier (passive) -

Features • Complete system for the strain-measurement on one tie bar • Direct display of strain values in µe, kN or t • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 1- channel digital monitor DU1D • Battery operation possible (optional) / not rechargeable • Very compact and easy to use system

Features • Complete system for the strain-measurement on one tie bar • Direct display of strain values in µe, kN or t • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 1- channel digital monitor DU1D • Battery operation possible (optional) / not rechargeable • Very compact and easy to use system -

Features • Complete system for the simultaneous strain-measurement on up to four tie bars • Direct display of strain values in µe, kN or t • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 4- channel digital monitor DU4D • USB connection for tie bar adjustment software (optional) • Very compact and easy to use system

Features • Complete system for the simultaneous strain-measurement on up to four tie bars • Direct display of strain values in µe, kN or t • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 4- channel digital monitor DU4D • USB connection for tie bar adjustment software (optional) • Very compact and easy to use system -

Features • Complete system for the simultaneous strain-measurement on up to four tie bars • Direct display of strain values in µe, kN or t (via our Inspectmate software) • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 4- channel digital monitor-box DU-4USB • USB connection for tie bar adjustment software and power supply • Very compact and easy to use system

Features • Complete system for the simultaneous strain-measurement on up to four tie bars • Direct display of strain values in µe, kN or t (via our Inspectmate software) • Quick and non-destructive assembly with magnetic press-on technology • High accuracy and linearity in tension and pressure (like bonded strain gauges) • Ideal for use on presses, injection-moulding and die-casting machines • Application on tie bars with a diameter of 45mm or higher and flat surfaces • Dynamic applications • 4- channel digital monitor-box DU-4USB • USB connection for tie bar adjustment software and power supply • Very compact and easy to use system -

Features • Measure strain in any direction in seconds • Smallest press-on sensor with magnet mounting • Direct surface strain reading like bonded strain gages, high linearity on tension and compression • Quick and easy mounting on magnetic structures • Calibrated sensor (K=2.00) for dynamic applications • Ideal for checking FEM calculations and for stress analysis on flat steel structures • Without amplifier (passiv) • External amplifier recommended (e.g. MBA100; VDA, Monitor DU-1D

Features • Measure strain in any direction in seconds • Smallest press-on sensor with magnet mounting • Direct surface strain reading like bonded strain gages, high linearity on tension and compression • Quick and easy mounting on magnetic structures • Calibrated sensor (K=2.00) for dynamic applications • Ideal for checking FEM calculations and for stress analysis on flat steel structures • Without amplifier (passiv) • External amplifier recommended (e.g. MBA100; VDA, Monitor DU-1D -

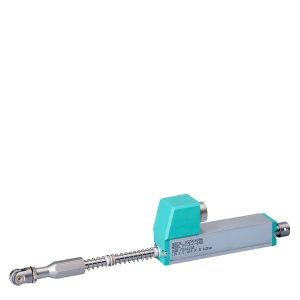

Main Characteristics • Absolute transducer • Strokes from 50 to 4000mm (RK-2-_ _ _ _ -N/E/S) • Digital output RS422 Start/Stop (RK-2-_ _ _ _ -S) • Direct analog output (RK-2-_ _ _ _ -N/K/E) • Operating temperature: -30...+90°C • Resistance to vibration (DIN IEC68T2/6 20g) • Power supply 18Vdc...30Vdc • Optional 12Vdc power supply (RK-2-_ _ _ _ -K) • The digital version (RK-2-_ _ _ _ -S) allows the remote connection (max. 50 m) of optional electronics for use of advanced analog (EKA)

Main Characteristics • Absolute transducer • Strokes from 50 to 4000mm (RK-2-_ _ _ _ -N/E/S) • Digital output RS422 Start/Stop (RK-2-_ _ _ _ -S) • Direct analog output (RK-2-_ _ _ _ -N/K/E) • Operating temperature: -30...+90°C • Resistance to vibration (DIN IEC68T2/6 20g) • Power supply 18Vdc...30Vdc • Optional 12Vdc power supply (RK-2-_ _ _ _ -K) • The digital version (RK-2-_ _ _ _ -S) allows the remote connection (max. 50 m) of optional electronics for use of advanced analog (EKA) -

Main Characteristics • Absolute transducer • Strokes from 50 to 4000mm (RK-4-_ _ _ _ -N/E/R) • Direct analog output (RK-4-_ _ _ _ -N/K/E) • Reverse analog output (RK-4-_ _ _ _ -R) • Operating temperature: -30...+90°C • Resistance to vibration (DIN IEC68T2/6 20g) • Power supply 18Vdc...30Vdc • Optional 12Vdc power supply (RK-4-_ _ _ _ -K)

Main Characteristics • Absolute transducer • Strokes from 50 to 4000mm (RK-4-_ _ _ _ -N/E/R) • Direct analog output (RK-4-_ _ _ _ -N/K/E) • Reverse analog output (RK-4-_ _ _ _ -R) • Operating temperature: -30...+90°C • Resistance to vibration (DIN IEC68T2/6 20g) • Power supply 18Vdc...30Vdc • Optional 12Vdc power supply (RK-4-_ _ _ _ -K) -

S55 .. S300 Series Family

S55 .. S300 Series Family- S55-PP 2000 - 6000 l/h

- S110-PP 2000 - 14000 l/h

- S150-PP 2000 - 18000 l/h

- S220-PP 10 - 24 m3/h

- S300-PP 10 - 32 m3/h

-

Features • Small press-on sensor with one-hole mounting • Direct measurement of surface strain • Without amplifier (passiv) • High accuracy and linearity in tension and pressure (like bonded strain gauges) • For dynamic applications • Used on presses, injection moulding and die-casting machines • Quick and easy mounting • Protected against overload • Optional accessories: - Signal amplifier VDA - Monitor DU-1D

Features • Small press-on sensor with one-hole mounting • Direct measurement of surface strain • Without amplifier (passiv) • High accuracy and linearity in tension and pressure (like bonded strain gauges) • For dynamic applications • Used on presses, injection moulding and die-casting machines • Quick and easy mounting • Protected against overload • Optional accessories: - Signal amplifier VDA - Monitor DU-1D -

Features • Direct measurement of surface strain • With high grade variable digital amplifier • Amplifies the signal on the spot, avoiding EMC problems • High accuracy and linearity in tension and pressure (like bonded strain gauges) • For dynamic applications • Used on presses, injection moulding and die-casting machines • Quick and easy mounting • Protected against overload

Features • Direct measurement of surface strain • With high grade variable digital amplifier • Amplifies the signal on the spot, avoiding EMC problems • High accuracy and linearity in tension and pressure (like bonded strain gauges) • For dynamic applications • Used on presses, injection moulding and die-casting machines • Quick and easy mounting • Protected against overload