-

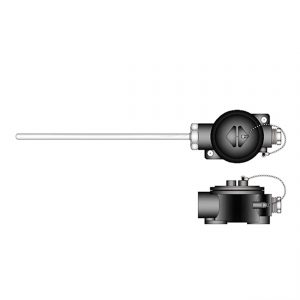

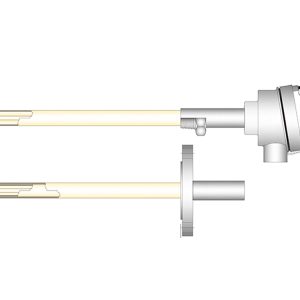

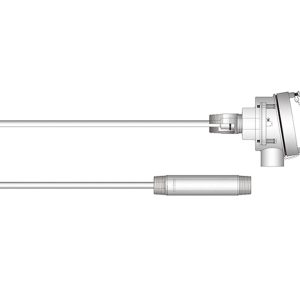

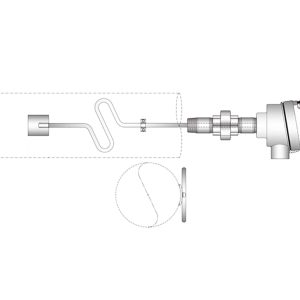

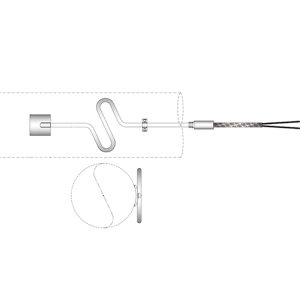

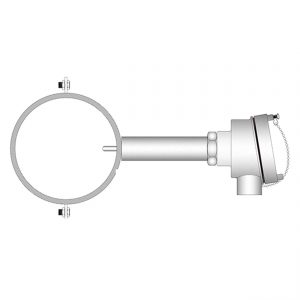

What is RTD? Resistance thermometers, also called Resistance Temperature Detector (RTD), are sensors used to measure temperature by correlating the resistance of the RTD element with temperature. Most RTD elements consist of a length of fine coiled wire wrapped around a ceramic or glass core. The element is usually quite fragile, so it's often placed inside a sheathed probe to protect it. The RTD element is made from a pure material, typically platinum, nickel, or copper. The material has a predictable change in resistance as the temperature changes that is used to determine temperature.

What is RTD? Resistance thermometers, also called Resistance Temperature Detector (RTD), are sensors used to measure temperature by correlating the resistance of the RTD element with temperature. Most RTD elements consist of a length of fine coiled wire wrapped around a ceramic or glass core. The element is usually quite fragile, so it's often placed inside a sheathed probe to protect it. The RTD element is made from a pure material, typically platinum, nickel, or copper. The material has a predictable change in resistance as the temperature changes that is used to determine temperature. -

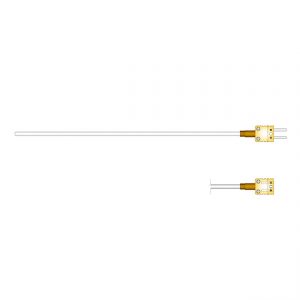

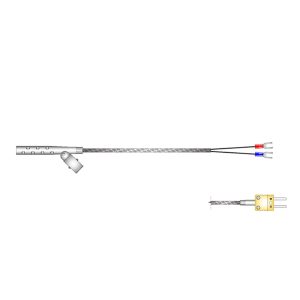

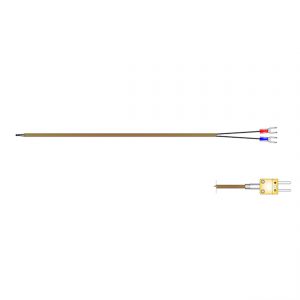

What is Thermocouple? A thermocouple is a temperature-measuring device consisting of two dissimilar conductors that contact each other at one or more spots, where temperature diffirential experienced by the different conductors (or semiconductors). Thermocouples are a widely used type of temperature sensor for measurement and control, and can also convert a temperature gradient into electricity.

What is Thermocouple? A thermocouple is a temperature-measuring device consisting of two dissimilar conductors that contact each other at one or more spots, where temperature diffirential experienced by the different conductors (or semiconductors). Thermocouples are a widely used type of temperature sensor for measurement and control, and can also convert a temperature gradient into electricity. -

Features • Universal input configurable from faceplate • Accuracy better than 0.2% f.s. under nominal conditions • Control output: relay, logic, Triac , continuous, digital insulated • Hot/cold function with selection of cooling fluid • 3 alarms with completely configurable function • Analog retransmission output • Isolated digital input with configurable function • Auxiliary input for CT (TA) (50mAac) • Heater break or probe short-circuit alarm • Self-tuning, Auto-tuning, Soft-start, bumpless Man/Auto function • Double set, set ramp, timed output function • Optically isolated RS485 serial line.Protocol: GEFRAN CENCAL or MODBUS RTU • Self-diagnosis • Rapid configuration from PC with Winstrum packet

Features • Universal input configurable from faceplate • Accuracy better than 0.2% f.s. under nominal conditions • Control output: relay, logic, Triac , continuous, digital insulated • Hot/cold function with selection of cooling fluid • 3 alarms with completely configurable function • Analog retransmission output • Isolated digital input with configurable function • Auxiliary input for CT (TA) (50mAac) • Heater break or probe short-circuit alarm • Self-tuning, Auto-tuning, Soft-start, bumpless Man/Auto function • Double set, set ramp, timed output function • Optically isolated RS485 serial line.Protocol: GEFRAN CENCAL or MODBUS RTU • Self-diagnosis • Rapid configuration from PC with Winstrum packet -

What is RTD? Resistance thermometers, also called Resistance Temperature Detectors (RTD), are sensors used to measure temperature by correlating the resistance of the RTD element with temperature. Most RTD elements consist of a length of fine coiled wire wrapped around a ceramic or glass core. The element is usually quite fragile, so it's often placed inside a sheathed probe to protect it. The RTD element is made from a pure material, typically platinum, nickel, or copper. The material has a predictable change in resistance as the temperature changes that is used to determine temperature.

What is RTD? Resistance thermometers, also called Resistance Temperature Detectors (RTD), are sensors used to measure temperature by correlating the resistance of the RTD element with temperature. Most RTD elements consist of a length of fine coiled wire wrapped around a ceramic or glass core. The element is usually quite fragile, so it's often placed inside a sheathed probe to protect it. The RTD element is made from a pure material, typically platinum, nickel, or copper. The material has a predictable change in resistance as the temperature changes that is used to determine temperature. -

Features

Features- Operator interface with large LCD Display, customizable, with choice of colors

- Scrolling diagnostics messages, configurable, in the selected language

- Easy, guided configuration, copy/paste parameters even with power off

- Preventive maintenance with energy counters (kWh) and load switching

- 16 function block applications

- Timer, setpoint and algorithm programmer for controlling motorized valves

- Advanced tuning of control parameters

- Different password levels

- Universal input configurable for thermocouples, resistance thermometers, linear inputs

- Remote setpoint input

- Relay, logic, isolated analog outputs

- Up to two CT inputs for interrupted load diagnostics

- RS485 serial communication in Modbus RTU

- Removable faceplate for immediate replacement

- Sampling time 60ms

-

Features • Universal input configurable from faceplate • Accuracy better than 0.2% f.s. under nominal conditions • Control output: relay, logic, Triac or continuous • Hot/cold function with selection of cooling fluid • 3 alarms with completely configurable function • Analog retransmission output • Up to 2 isolated digital inputs with configurable function • Isolated digital input with configurable function • Auxiliary input for CT (TA) (50mAac) • Heater break or probe short-circuit alarm • Self-tuning, Auto-tuning, Soft-start, bumpless Man/Auto function • Double set, set ramp, timed output function • Optically isolated RS485 serial line. Protocol: GEFRAN MODBUS RTU • Self-diagnosis • Rapid configuration from PC with Winstrum packet

Features • Universal input configurable from faceplate • Accuracy better than 0.2% f.s. under nominal conditions • Control output: relay, logic, Triac or continuous • Hot/cold function with selection of cooling fluid • 3 alarms with completely configurable function • Analog retransmission output • Up to 2 isolated digital inputs with configurable function • Isolated digital input with configurable function • Auxiliary input for CT (TA) (50mAac) • Heater break or probe short-circuit alarm • Self-tuning, Auto-tuning, Soft-start, bumpless Man/Auto function • Double set, set ramp, timed output function • Optically isolated RS485 serial line. Protocol: GEFRAN MODBUS RTU • Self-diagnosis • Rapid configuration from PC with Winstrum packet -

What is RTD? Resistance thermometers, also called Resistance Temperature Detectors (RTD), are sensors used to measure temperature by correlating the resistance of the RTD element with temperature. Most RTD elements consist of a length of fine coiled wire wrapped around a ceramic or glass core. The element is usually quite fragile, so it's often placed inside a sheathed probe to protect it. The RTD element is made from a pure material, typically platinum, nickel or copper. The material has a predictable change in resistance as the temperature changes are used to determine temperature.

What is RTD? Resistance thermometers, also called Resistance Temperature Detectors (RTD), are sensors used to measure temperature by correlating the resistance of the RTD element with temperature. Most RTD elements consist of a length of fine coiled wire wrapped around a ceramic or glass core. The element is usually quite fragile, so it's often placed inside a sheathed probe to protect it. The RTD element is made from a pure material, typically platinum, nickel or copper. The material has a predictable change in resistance as the temperature changes are used to determine temperature. -

What is Thermocouple? A thermocouple is a temperature-measuring device consisting of two dissimilar conductors that contact each other at one or more spots, where temperature diffirential experienced by the different conductors (or semiconductors). Thermocouples are a widely used type of temperature sensor for measurement and control, and can also convert a temperature gradient into electricity.

What is Thermocouple? A thermocouple is a temperature-measuring device consisting of two dissimilar conductors that contact each other at one or more spots, where temperature diffirential experienced by the different conductors (or semiconductors). Thermocouples are a widely used type of temperature sensor for measurement and control, and can also convert a temperature gradient into electricity. -

Features • Operator interface with large LCD Display, customizable, with choice of colors • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/ paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 16 function block applications • Timer, setpoint and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • Universal input configurable for thermocouples, resistance thermometers, linear inputs • Remote setpoint input • Relay, logic, isolated analog outputs • Up to two CT inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU • Removable faceplate for immediate replacement • Sampling time 60 ms

Features • Operator interface with large LCD Display, customizable, with choice of colors • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/ paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 16 function block applications • Timer, setpoint and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • Universal input configurable for thermocouples, resistance thermometers, linear inputs • Remote setpoint input • Relay, logic, isolated analog outputs • Up to two CT inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU • Removable faceplate for immediate replacement • Sampling time 60 ms -

Features

Features- Operator interface with large LCD Display,customizable, with choice of colors

- Scrolling diagnostics messages, configurable, in the selected language

- Easy, guided configuration, copy/paste parameters even with power off

- Preventive maintenance with energy counters (kWh) and load switching

- 16 function block applications

- Timer, setpoint and algorithm programmer for controlling motorized valves

- Advanced tuning of control parameters

- Different password levels

- Universal input configurable for thermocouples, resistance thermometers, linear inputs

- Remote setpoint input

- Relay, logic, isolated analog outputs

- CT inputs for interrupted load diagnostics

- RS485 serial communication in Modbus RTU

- Removable faceplate for immediate replacement

- Sampling time 60ms

- 10V power supply for potentiometer and 24V for transmitter

-

Features • Universal input configurable from the faceplate • Acquisition of the input signal every 120msec ; resolution 30000steps • Two control outputs: relay, logic or analogue with Open/Close valve function • 3 configurable alarms • 2 analogue outputs (retransmission) • 2 digital inputs with configurable function • Auxiliary input for valve position potentiometer feedback • Heater Break or shortcircuit probe alarm • Self and Auto-tuning, Soft-start, Local/Remote setpoint, Auto/Man • Multiset function, timer set ramp

Features • Universal input configurable from the faceplate • Acquisition of the input signal every 120msec ; resolution 30000steps • Two control outputs: relay, logic or analogue with Open/Close valve function • 3 configurable alarms • 2 analogue outputs (retransmission) • 2 digital inputs with configurable function • Auxiliary input for valve position potentiometer feedback • Heater Break or shortcircuit probe alarm • Self and Auto-tuning, Soft-start, Local/Remote setpoint, Auto/Man • Multiset function, timer set ramp -

Features • Operator interface with large LCD Display, customizable, with choice of colors • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 16 function block applications • Timer, set point and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • Universal input configurable for thermocouples, resistance thermometers, linear inputs • Remote set point input • Relay, logic, isolated analog outputs • Up to two CT inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU • Removable faceplate for immediate replacement • Sampling time 60ms

Features • Operator interface with large LCD Display, customizable, with choice of colors • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 16 function block applications • Timer, set point and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • Universal input configurable for thermocouples, resistance thermometers, linear inputs • Remote set point input • Relay, logic, isolated analog outputs • Up to two CT inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU • Removable faceplate for immediate replacement • Sampling time 60ms -

Features • Operator interface with large LCD Display and three configurable bargraphs • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 32 function block applications • 8 Math application blocks • Timer, setpoint and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • 2 setpoint programmers (192 steps in 16 programs, or 12 programs with 16 fixed steps each) • 1 ingresso analogico lineare configurabile per funzioni ausiliarie • 2 PID control loops • 2 Programmatori di setpoint (192 passi in 16 programmi oppure 12 programmi da 16 passi fissi ciascuno) • Relay, logic, isolated analog outputs • Up to two TA inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU slave • RS485 serial communication in Modbus RTU master for reading/ writing information to Modbus slave devices • Ethernet Modbus TCP communication in Slave mode • Web server for browser access to web pages residing in the devvice, for monitoring and setting parameters • Bridge function for creation of Modbus RTU 485 sub-network • Weekly clock\calendar with RTC • Removable faceplate for immediate replacement • Accuracy 0,1%, sampling time 60 ms

Features • Operator interface with large LCD Display and three configurable bargraphs • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 32 function block applications • 8 Math application blocks • Timer, setpoint and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • 2 setpoint programmers (192 steps in 16 programs, or 12 programs with 16 fixed steps each) • 1 ingresso analogico lineare configurabile per funzioni ausiliarie • 2 PID control loops • 2 Programmatori di setpoint (192 passi in 16 programmi oppure 12 programmi da 16 passi fissi ciascuno) • Relay, logic, isolated analog outputs • Up to two TA inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU slave • RS485 serial communication in Modbus RTU master for reading/ writing information to Modbus slave devices • Ethernet Modbus TCP communication in Slave mode • Web server for browser access to web pages residing in the devvice, for monitoring and setting parameters • Bridge function for creation of Modbus RTU 485 sub-network • Weekly clock\calendar with RTC • Removable faceplate for immediate replacement • Accuracy 0,1%, sampling time 60 ms -

Features • Security of the Push-Pull self-latching system • Unipole types transmitting current up to 230 A and multipole types with up to 106 contacts • 60° screening for full EMC shielding • Solder or print contacts (straight or elbow) • Polarisation by stepped insert (half-moon) fitted with male and female contacts

Features • Security of the Push-Pull self-latching system • Unipole types transmitting current up to 230 A and multipole types with up to 106 contacts • 60° screening for full EMC shielding • Solder or print contacts (straight or elbow) • Polarisation by stepped insert (half-moon) fitted with male and female contacts -

Features • Operator interface with color touch screen display, 3.5 “ • Up to 8 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 200 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Management of active and historic alarms • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection

Features • Operator interface with color touch screen display, 3.5 “ • Up to 8 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 200 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Management of active and historic alarms • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection -

Features • Operator interface with color touch screen display, 7” • Up to 16 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 250 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection

Features • Operator interface with color touch screen display, 7” • Up to 16 PID control loops • Cascade, ratio and valve PID controls • Profile programmer with ramps and retention; synchronous and asynchronous • Up to 250 Programs with 50 segments • 3 password protected user levels • Energy meter (kWh) • Configurable logic operations • Configurable math functions • Data Log with Real Time Clock • Batch Report management • Open format files (CSV) or encrypted for DataLog and production batches • Setting up custom pages • Active and historical alarm management • USB for data export and parameter cloning • Control parameter advanced tuning • Configurable analogue and digital I/O signals • HMI/SCADA/PLC data exchange via Ethernet Modbus TCP • Message language selection -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower Watt densities available for highly viscous solutions & technical acids -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Optional patented purge feature promotes longer heater life • Lower Watt densities available for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Optional patented purge feature promotes longer heater life • Lower Watt densities available for highly viscous solutions & technical acids -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Optional patented purge feature promotes a longer heater life by reducing chemical permeation • Lower Watt densities available for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Optional patented purge feature promotes a longer heater life by reducing chemical permeation • Lower Watt densities available for highly viscous solutions & technical acids -

Features • Universal input configurable from faceplate • Accuracy better than 0.2% f.s. under nominal conditions • Control output: relay, logic, Triac , continuous, digital insulated • Hot/cold function with selection of cooling fluid • 3 alarms with completely configurable function • Analog retransmission output • Isolated digital input with configurable function • Auxiliary input for CT (TA) (50mAac) • Heater break or probe short-circuit alarm • Self-tuning, Auto-tuning, Soft-start, bumpless Man/Auto function • Double set, set ramp, timed output function • Optically isolated RS485 serial line. Protocol: GEFRAN CENCAL or MODBUS RTU • Self-diagnosis • Rapid configuration from PC with Winstrum packet

Features • Universal input configurable from faceplate • Accuracy better than 0.2% f.s. under nominal conditions • Control output: relay, logic, Triac , continuous, digital insulated • Hot/cold function with selection of cooling fluid • 3 alarms with completely configurable function • Analog retransmission output • Isolated digital input with configurable function • Auxiliary input for CT (TA) (50mAac) • Heater break or probe short-circuit alarm • Self-tuning, Auto-tuning, Soft-start, bumpless Man/Auto function • Double set, set ramp, timed output function • Optically isolated RS485 serial line. Protocol: GEFRAN CENCAL or MODBUS RTU • Self-diagnosis • Rapid configuration from PC with Winstrum packet -

Features • Operator interface with large LCD Display, customizable, with choice of colors • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 16 function block applications • Timer, set point and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • Universal input configurable for thermocouples, resistance thermometers, linear inputs • Remote set point input • Relay, logic, isolated analog outputs • Up to two CT inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU • Removable faceplate for immediate replacement • Sampling time 60ms

Features • Operator interface with large LCD Display, customizable, with choice of colors • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even with power off • Preventive maintenance with energy counters (kWh) and load switching • 16 function block applications • Timer, set point and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • Universal input configurable for thermocouples, resistance thermometers, linear inputs • Remote set point input • Relay, logic, isolated analog outputs • Up to two CT inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU • Removable faceplate for immediate replacement • Sampling time 60ms -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit. • Lower watt densities for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit. • Lower watt densities for highly viscous solutions & technical acids -

Features • Operator interface with large LCD Display and three configurable bargraphs • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even withe power off • Preventive maintenance with energy counters (kWh) and load switching • 32 function block applications • 8 Math application blocks • Timer, set point and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • 2 Universal inputs configurable for thermocouples, resistance thermometers, linear inputs • 1 linear analog input configurable for auxiliary functions • 2 PID control loops • 2 set point programmers (192 steps in 16 programs, or 12 programs with 16 fixed steps each) • Relay, logic, isolated analog outputs • Up to two TA inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU slave • RS485 serial communication in Modbus RTU master for reading/ writing information to Modbus slave devices • Ethernet Modbus TCP communication in Slave mode • Web server for browser access to web pages residing in the device, for monitoring and setting parameters • Bridge function for creation of Modbus RTU 485 sub-network • Weekly clock\calendar with RTC • Removable faceplate for immediate replacement • Accuracy 0,1%, sampling time 60 ms

Features • Operator interface with large LCD Display and three configurable bargraphs • Scrolling diagnostics messages, configurable, in the selected language • Easy, guided configuration, copy/paste parameters even withe power off • Preventive maintenance with energy counters (kWh) and load switching • 32 function block applications • 8 Math application blocks • Timer, set point and algorithm programmer for controlling motorized valves • Advanced tuning of control parameters • Different password levels • 2 Universal inputs configurable for thermocouples, resistance thermometers, linear inputs • 1 linear analog input configurable for auxiliary functions • 2 PID control loops • 2 set point programmers (192 steps in 16 programs, or 12 programs with 16 fixed steps each) • Relay, logic, isolated analog outputs • Up to two TA inputs for interrupted load diagnostics • RS485 serial communication in Modbus RTU slave • RS485 serial communication in Modbus RTU master for reading/ writing information to Modbus slave devices • Ethernet Modbus TCP communication in Slave mode • Web server for browser access to web pages residing in the device, for monitoring and setting parameters • Bridge function for creation of Modbus RTU 485 sub-network • Weekly clock\calendar with RTC • Removable faceplate for immediate replacement • Accuracy 0,1%, sampling time 60 ms -

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower watt densities for highly viscous solutions & technical acids

Features • Inert to most aqueous acid, alkaline, anodizing, & pickling solutions up to 100°C (212°F) • Rugged, heavy wall PTFE covered stainless steel element reduces permeation. Guaranteed 100% pinhole free • Space saving & long service life with low Watt density design of 10 W/in2 (1.5 W/cm2) • Vapor-resistant, flame retardant polypropylene terminal enclosure with 3 ft (.9m) flexible PVC liquid tight conduit • Lower watt densities for highly viscous solutions & technical acids -

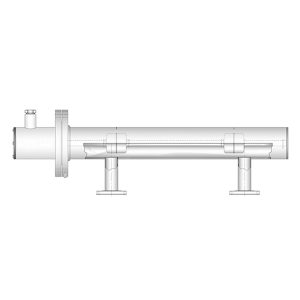

Basket strainers are designed to protect pumps for large incoming particles. This can prevent serious damage of your pumps, and will therefore reduce maintenance cost and process down time. [ Click here for more details ]

Basket strainers are designed to protect pumps for large incoming particles. This can prevent serious damage of your pumps, and will therefore reduce maintenance cost and process down time. [ Click here for more details ] -

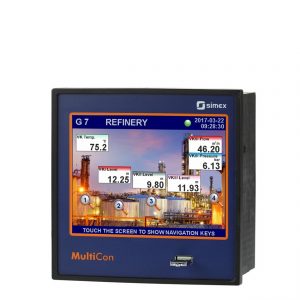

Features

Features- MultiCon = Meter + Controller + Recorder + HMI + SCADA in one package

- stable firmware based on Linux

- 41 available input/output modules

- 90 logical channels

- colour LCD display 5.7" TFT, with touchscreen

- recording data with maximum speed 10Hz (ten samples per second)

- 2 or 4 GB internal data memory

- RS-485 (Modbus RTU), USB Host, Ethernet communication

- panel, compact device in 144 x 144 mm case

-

Features

Features- MultiCon = Meter + Controller + Recorder + HMI + SCADA in one package

- stable firmware based on Linux

- 27 available input/output modules

- 60 logical channels

- colour LCD display 3.5" TFT, with touchscreen

- recording data with maximum speed 10Hz (ten samples per second)

- 2 or 4 GB internal data memory

- RS-485 (Modbus RTU), USB Host, Ethernet communication

- panel, compact device in 96 x 96 mm case

-

Features

Features- MultiCon = Meter + Controller + Recorder + HMI + SCADA in one package

- Stable firmware based on Linux

- 13 available input/output blocks

- Colour LCD display 3,5" TFT, with touchscreen

- Recording data with maximum speed 10Hz (ten samples per second)

- 2 or 4 GB internal data memory

- RS-485 (Modbus RTU), USB Host, Ethernet communication

- Wall mounted IP 65 case

-

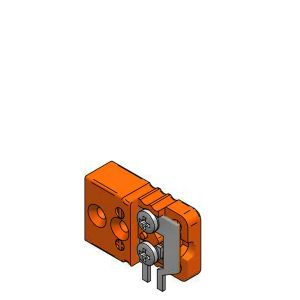

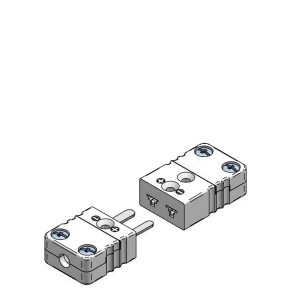

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts. • Copper pins with silver plating • Rugged one body design. • Stainless steel locking clip • Locking Connector Jack Miniature also accepts Miniature • Connector Plugs without locking feature

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts. • Copper pins with silver plating • Rugged one body design. • Stainless steel locking clip • Locking Connector Jack Miniature also accepts Miniature • Connector Plugs without locking feature -

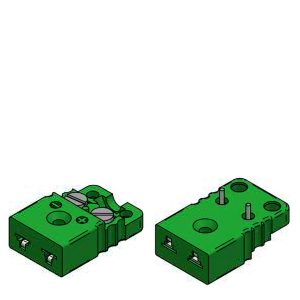

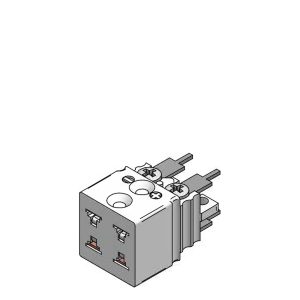

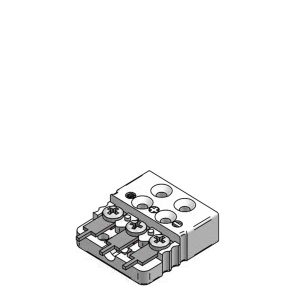

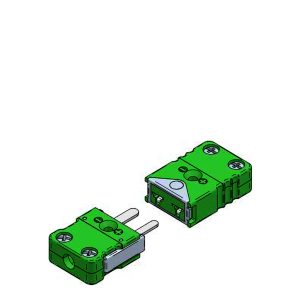

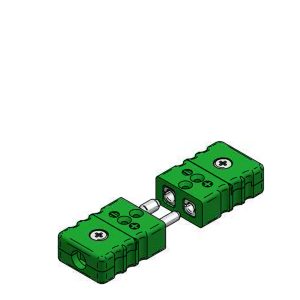

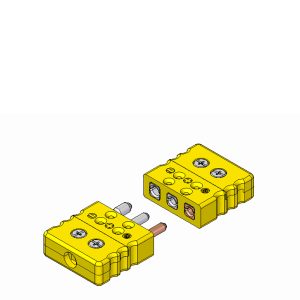

Features • Glass filled high quality thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins ensure proper connection • Easy wire connection through sandwich construction • Molded barriers prevent short circuit • Rugged one body design • Stainless Steel screws with Phillips head • Stainless steel locking clip • Locking Connector Miniature also fits on our part numbers CMP and CMJ

Features • Glass filled high quality thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins ensure proper connection • Easy wire connection through sandwich construction • Molded barriers prevent short circuit • Rugged one body design • Stainless Steel screws with Phillips head • Stainless steel locking clip • Locking Connector Miniature also fits on our part numbers CMP and CMJ -

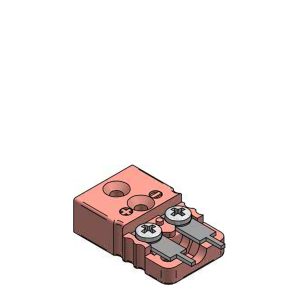

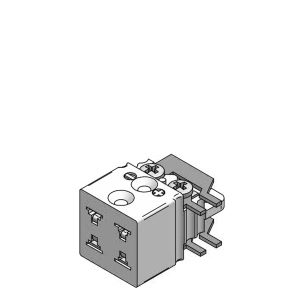

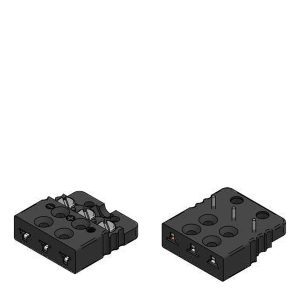

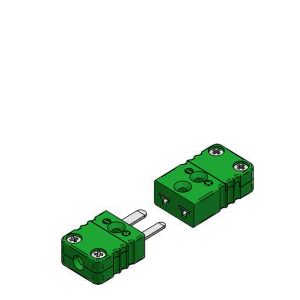

Features • Glass filled high quality thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins ensure proper connection • Easy wire connection through sandwich construction • Molded barriers prevent short circuit • Rugged one body design • Stainless Steel screws with Phillips head

Features • Glass filled high quality thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins ensure proper connection • Easy wire connection through sandwich construction • Molded barriers prevent short circuit • Rugged one body design • Stainless Steel screws with Phillips head -

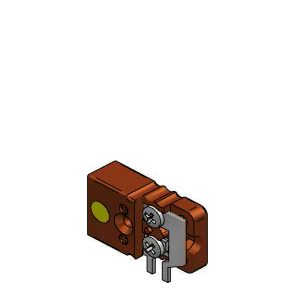

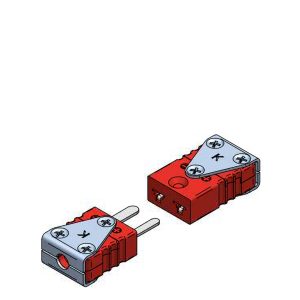

Features • Body of ultra high temp thermoset compound with original thermocouple material pins and springloaded inserts. • Polarized pins ensure proper connection. • Easy wire connection through sandwich construction. • Molded barriers prevent short circuit. • Rugged one body design. • Stainless steel bracket and screws for usage in robust environment

Features • Body of ultra high temp thermoset compound with original thermocouple material pins and springloaded inserts. • Polarized pins ensure proper connection. • Easy wire connection through sandwich construction. • Molded barriers prevent short circuit. • Rugged one body design. • Stainless steel bracket and screws for usage in robust environment -

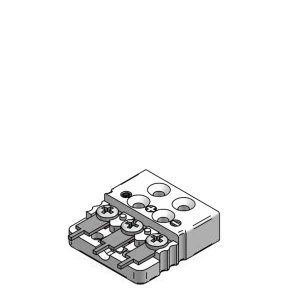

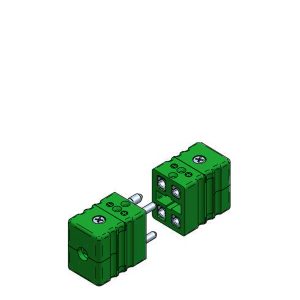

Features • Glass filled high quality thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins • Central cover screw design for quick wiring • Molded barriers prevent short circuit • Captive cover screw for easy assembly • Easy wire connection through sandwich construction • Stainless Steel screws with Phillips head

Features • Glass filled high quality thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins • Central cover screw design for quick wiring • Molded barriers prevent short circuit • Captive cover screw for easy assembly • Easy wire connection through sandwich construction • Stainless Steel screws with Phillips head -

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins • Central cover screw design for quick wiring • Molded barriers prevent short circuit • Captive cover screw for easy assembly • Connects with standard horizontal and vertical panels

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins • Central cover screw design for quick wiring • Molded barriers prevent short circuit • Captive cover screw for easy assembly • Connects with standard horizontal and vertical panels -

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins • Central cover screw design for quick wiring • Molded barriers prevent short circuit • Captive cover screw for easy assembly • Connects with standard horizontal and vertical panels

Features • Glass filled thermoplastic body with original thermocouple material pins and springloaded inserts • Polarized pins • Central cover screw design for quick wiring • Molded barriers prevent short circuit • Captive cover screw for easy assembly • Connects with standard horizontal and vertical panels